Back

As a grid-scale energy storage system, flow batteries have gained increasing attention as a means to address the challenges associated with fluctuations and intermittency in renewable energy sources. Vanadium redox flow batteries (VRFBs) have emerged as promising solutions for stationary grid energy storage due to their high efficiency, scalability, safety, near room…

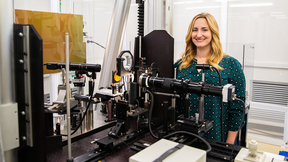

Lawrence Livermore National Laboratory (LLNL) materials scientist Kate Elder has been selected as a Fulbright U.S. Scholar and will conduct research in Finland. Elder’s project, “Establishing Process-Structure Links During Additive Manufacturing of High Entropy Alloys,” will lead to the manufacture of lighter and stronger parts, perfect for high-temperature applications…

Getting the chance to meet and mingle with scientists who have achieved Nobel Prize winning greatness will be the reality for five Lawrence Livermore National Laboratory (LLNL) postdoctoral appointees selected to attend the 73rd annual Lindau Nobel Laureate meetings. Tina Ebert, Elizabeth Grace and Raspberry Simpson were selected as the 2024 LLNL cohort; Tomi Akindele and…

If the sun is too bright, you might don a pair of sunglasses or a hat to prevent glare from damaging your eyes. Researchers at Lawrence Livermore National Laboratory (LLNL) are using this same strategy to mitigate damage to valuable optics vital to the National Ignition Facility (NIF). Every time NIF fires, its lasers can harm the optics along its beamlines, causing…

Editor’s note: The principal mission of Lawrence Livermore National Laboratory (LLNL)’s National Ignition Facility (NIF) is to support the National Nuclear Security Administration’s science-based Stockpile Stewardship Program — and with the achievement of fusion ignition in 2022 at NIF, LLNL is further exploring the possible use of nuclear fusion as a future energy source…

Four Lawrence Livermore National Laboratory (LLNL) researchers have partnered with Los Angeles-based SoCalGas and Munich, Germany-based Electrochaea to develop an electrobioreactor to allow excess renewable electricity from wind and solar sources to be stored in chemical bonds as renewable natural gas. When renewable electricity supply exceeds demand, electric-utility…

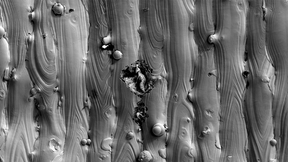

Like a hidden enemy, pitting corrosion attacks metal surfaces, making it difficult to detect and control. This type of corrosion, primarily caused by prolonged contact with seawater in nature, is especially problematic for naval vessels. In a recent paper published in Nature Communications, Lawrence Livermore National Laboratory (LLNL) scientists delved into the mysterious…

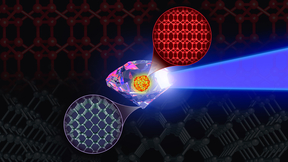

Diamond is the strongest material known. However, another form of carbon has been predicted to be even tougher than diamond. The challenge is how to create it on Earth. The eight-atom body-centered cubic (BC8) crystal is a distinct carbon phase: not diamond, but very similar. BC8 is predicted to be a stronger material, exhibiting a 30% greater resistance to compression…

In the fall of 2023, Lawrence Livermore National Laboratory (LLNL) scientists Sijia Huang and Michael Ford participated in the Department of Energy’s Energy I-Corps Program, an immersive eight-week entrepreneurial boot camp that teaches scientists and engineers the tools of the trade for commercializing technology from the Lab to the marketplace. A major part of the…

Lawrence Livermore National Laboratory’s (LLNL) popular outreach series, “Science on Saturday,” will continue its programming into March at the Grand Theatre Center for the Arts in Tracy, California. The talks are scheduled for March 2 and 9 and will focus on the theme “Magic of Materials.” The talks, which are geared toward middle and high school students, will begin at…

Lawrence Livermore National Laboratory (LLNL) employees, participating in five project teams, recently earned Department of Energy (DOE) Secretary’s Honor Awards. In addition, Karin King of the Livermore Field Office was honored for her role in the Leadership in Climate Action Team. Representing some of the highest internal, non-monetary recognition that DOE employees and…

TATB (1,3,5-triamino-2,4,6-trinitrobenzene) is an important explosive compound because of its extensive use in munitions and world-wide weapons systems. Despite its importance, researchers have been trying to understand its response to temperature extremes for the past 50 years. A Lawrence Livermore National Laboratory (LLNL) team has uncovered a new thermal decomposition…

Intense research efforts have been directed toward studying the electrochemical conversion of CO2, a major greenhouse gas, into platform chemicals and fuels. The success of this technology can enable decarbonization of some of the largest CO2 emitters including steel, cement and chemical manufacturing industries. Copper is unique in its ability to convert CO2 at low…

Six scientists at the Lawrence Livermore National Laboratory (LLNL) were recently granted awards through the Lab’s 2023 Academic Collaboration Team (ACT) annual call for proposals. Awards support university research partners for up to three years to perform research in collaboration with Lab scientists and offer an important way to build long-term connections with…

Lawrence Livermore National Laboratory's (LLNL) popular lecture series, “Science on Saturday,” returns Feb. 3 and runs through Feb. 24. The series offers four different lectures with the theme, “Magic of Materials.” Each lecture is presented by leading LLNL researchers who are joined by high-school science teachers. Below is the schedule of lectures, which can also be…

Lawrence Livermore National Laboratory (LLNL) researchers, along with scientists from more than a dozen institutions, have completed a first-of-its-kind high-resolution assessment of carbon dioxide (CO2) removal (CDR) in the United States. The report, “Roads to Removal: Options for Carbon Dioxide Removal in the United States,” charts a path for the United States to achieve…

Rising global temperatures are creating an increased demand for cooling as the number of air-conditioning units used worldwide is expected to triple by 2050. However, with 13% of the global population without access to electricity, solutions that can provide cooling without electricity are needed. In a study published in Materials Horizon, a Lawrence Livermore National…

Understanding laser material interactions has applications that include inertial confinement fusion, material research and equation of state studies. Laser ablation, and specifically increasing the pressure that can be achieved from a laser system, is a longstanding topic of scientific research with implications ranging from damage in layered devices like solar cells and…

In new experiments at Lawrence Livermore National Laboratory’s National Ignition Facility, scientists measured the extended X-ray absorption fine structure (EXAFS) of copper to probe its temperature under extreme pressure. The research appears in the journal Nature Communications. Dynamic compression experiments at high-energy-density laser facilities have expanded the…

For the second consecutive year, Lawrence Livermore National Laboratory (LLNL) hosted a group of student scholars and faculty members from Historically Black Colleges and Universities (HBCUs) on a recent five-day visit. LLNL’s goal is to develop the next wave of summer interns — and to build a strong pipeline of talent — from historically marginalized groups in science,…