Back

The University of California (UC) and Lawrence Livermore National Laboratory (LLNL) have a storied history going back to the founding of the Laboratory in 1952. The work conducted at the Lab since that time has benefited in many areas from successful collaboration with researchers and contributors within the UC system. In the spirit of continued collaboration, a UC Early…

Lawrence Livermore National Laboratory (LLNL) scientists and engineers have put together another first-rate year securing major grants through the Department of Energy’s (DOE) Technology Commercialization Fund (TCF). “We did quite well, although the diversity of the research projects funded wasn’t as broad as last year,” said Rich Rankin, the director of the Lab’s…

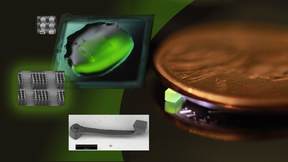

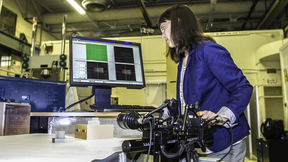

While 3D printing at the nanoscale — producing intricate features orders of magnitude smaller than the width of a human hair — has significant potential in industry and commercial applications, wide adoption has been impractical because of the slow speed and low throughput of the most widely used nanoprinting technique, two-photon lithography (TPL). But in the latest issue…

Representatives from more than 30 companies in the additive manufacturing (3D printing), automotive and aerospace industries got their first glimpse last week at Lawrence Livermore National Laboratory’s (LLNL) newest facility, the Advanced Manufacturing Laboratory, located in the Livermore Valley Open Campus (LVOC). The sneak preview was part of a "Partnering for Success"…

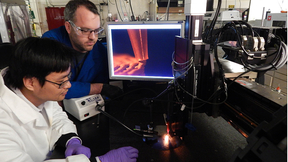

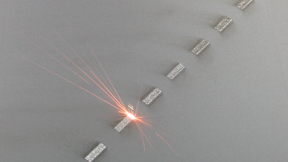

A technology originally developed to smooth out and pattern high-powered laser beams for the National Ignition Facility (NIF) can be used to 3D print metal objects faster than ever before, according to a new study by Lawrence Livermore researchers. A team of Lab scientists report the findings in the latest issue of Optics Express, published online on May 15. This new…

Metal 3D printing has enormous potential to revolutionize modern manufacturing. However, the most popular metal printing processes, which use lasers to fuse together fine metal powder, have their limitations. Parts produced using selective laser melting (SLM) and other powder-based metal techniques often end up with gaps or defects caused by a variety of factors. To…

LIVERMORE, California -- Now in its third year, Lawrence Livermore National Laboratory (LLNL) is once again partnering with the State Theatre in Modesto to bring "Science on Screen" to the theater one Saturday a month from February through April.Science on Screen is a free, educational program geared to middle-, high-school and college students and creatively pairs cutting…

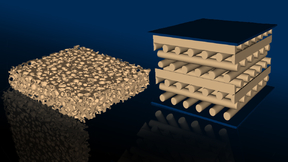

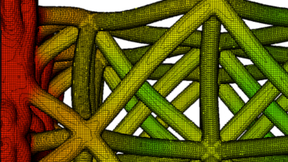

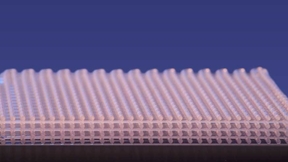

Lawrence Livermore National Laboratory (LLNL) material scientists have found that 3D-printed foam works better than standard cellular materials in terms of durability and long-term mechanical performance.Foams, also known as cellular solids, are an important class of materials with applications ranging from thermal insulation and shock-absorbing support cushions to…

While the most common method of metal 3D printing is growing exponentially, moving forward from producing prototypes to manufacturing critical parts will be possible only by reaching a fundamental understanding of the complex physics behind the process, according to a new paper authored by Lawrence Livermore National Laboratory (LLNL) researchers. The powder bed fusion…

Reactive composite materials are everywhere, from the life-saving air bags in your car to the dazzling pyrotechnics in Fourth of July fireworks. But one of the main drawbacks to using these materials has been the unpredictability of their reactions.Historically, the way to alter the performance in reactive materials (i.e. thermites) has been to either change the…

Researchers from Lawrence Livermore National Laboratory (LLNL) and a Bay Area company are joining forces to explore how design software can accelerate innovation for three-dimensional printing of advanced materials.Under an 18-month Cooperative Research and Development Agreement (CRADA), LLNL will use state-of-the-art software for generative design from San Rafael-based…

A new type of graphene aerogel will make for better energy storage, sensors, nanoelectronics, catalysis and separations.Lawrence Livermore National Laboratory researchers have made graphene aerogel microlattices with an engineered architecture via a 3D printing technique known as direct ink writing. The research appears in the April 22 edition of the journal, Nature…

LIVERMORE, Calif. – General Electric (GE) and Lawrence Livermore National Laboratory (LLNL) recently received $540,000 to develop open-source algorithms that will improve additive manufacturing of metal parts.The award is from America Makes, the National Additive Manufacturing Innovation Institute that’s focused on helping the U.S. grow capabilities and strength in 3D…

LIVERMORE, California — California employers have created a pipeline to train and educate active-duty service members and veterans for careers in advance manufacturing to fill a workforce shortage for a burgeoning industry.Lawrence Livermore and Lawrence Berkeley national laboratories, NASA Ames Research Center and NASA Jet Propulsion Laboratory and other employers are…

In 2014, Lawrence Livermore National Laboratory (LLNL) built on a 62-year tradition of translating basic science into technologies that ensure national security, address pressing real world problems and expand the boundaries of fundamental science.The top stories of the year are a reflection of the Laboratory’s ability to apply its core national security competencies to a…

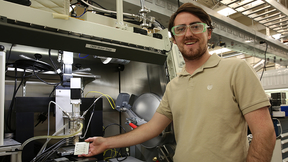

LIVERMORE, California – Lawrence Livermore National Laboratory researchers have developed an efficient method to measure residual stress in metal parts produced by powder-bed fusion additive manufacturing.This 3D printing process produces metal parts layer by layer using a high-energy laser beam to fuse metal powder particles. When each layer is complete, the build…

Materials like solid gels and porous foams are used for padding and cushioning, but each has its own advantages and limitations. Gels are effective as padding but are relatively heavy; gel performance can also be affected by temperature, and possesses a limited range of compression due to a lack of porosity. Foams are lighter and more compressible, but their performance is…

LIVERMORE, Calif. -Lawrence Livermore National Laboratory researchers have developed a new and more efficient approach to a challenging problem in additive manufacturing -- using selective laser melting, namely, the selection of appropriate process parameters that result in parts with desired properties. Selective laser melting (SLM) is a powder-based, additive…

Lawrence Livermore National Laboratory's additive manufacturing capabilities including hardware expertise, materials science R&D and high-performance computing were highlighted at a recent Silicon Valley forum.Held at theHigh Performance Computing Innovation CenterLivermore Valley Open Campus, the event drew a standing room only crowd of more than 80 people from…

Lawrence Livermore National Laboratory (LLNL) has entered into a technology development partnership with FATHOM, a company specializing in 3D printing and additive manufacturing.The collaboration combines FATHOM's advanced industry knowledge with LLNL's unique research and development capabilities and broad domain expertise in applied science and engineering to…