Looking at the importance of catalyst sites in electrochemical CO2 conversion

(Download Image)

(Download Image)

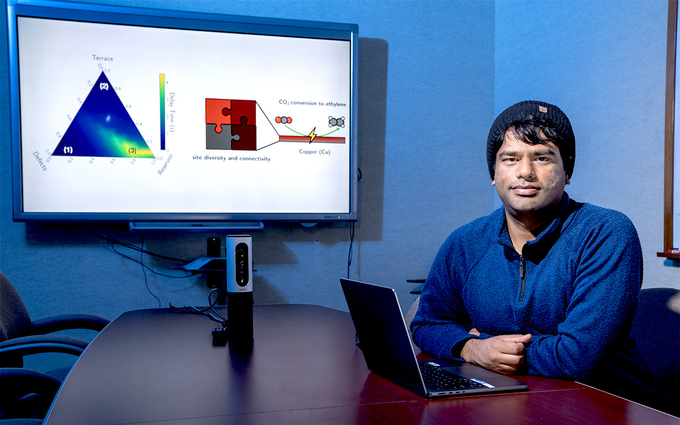

LLNL researcher Nitish Govindarajan displays a heatmap showing the effect of the active site type and concentration on the delay time and a schematic summarizing the key findings of this study. Photo by Blaise Douros/LLNL.

Intense research efforts have been directed toward studying the electrochemical conversion of CO2, a major greenhouse gas, into platform chemicals and fuels. The success of this technology can enable decarbonization of some of the largest CO2 emitters including steel, cement and chemical manufacturing industries.

Copper is unique in its ability to convert CO2 at low temperatures to a diverse range of products such as carbon monoxide, ethylene and ethanol at industrially viable current densities. As a result, there is widespread interest in understanding CO2 conversion on copper electrodes as efficient and stable CO2 electrolyzers.

In a recent study involving a multi-disciplinary team from Lawrence Livermore National Laboratory (LLNL), Lawrence Berkeley National Laboratory, University of California Berkeley and the Korea Advanced Institute of Science and Technology (KAIST), researchers used chemical transient kinetics and microkinetic modeling to understand the atomistic scale workings of copper electrodes during electrochemical conversion of carbon monoxide, a key reaction intermediate in electrochemical CO2 conversion. Their findings were published as an open-access article in the American Chemical Society journal ACS Catalysis.

Using a simple experimental protocol involving the repeated switching of gas feed from argon to carbon monoxide, researchers find that carbon monoxide conversion to multi-carbon products can proceed at the same rate for several seconds even after the gas feed is switched from carbon monoxide to argon (referred to as the delay time). This observation motivated the team to understand the origin of the delay time and its implications for designing efficient catalysts for this important reaction.

“Our surprising finding from this work is that the effective catalytic activity of the reaction improves when there is a larger fraction of less-active sites [termed reservoir sites]. We developed a microkinetic model involving three site types to explain our findings,” said LLNL researcher and co-first author Nitish Govindarajan.

“Our findings indicate that catalyst active sites cannot be analyzed in isolation from their neighbor sites. Rather, we must consider how the entire catalyst site network works cooperatively to establish a supply chain of reactants to the most active sites,” said LLNL co-principal investigator Christopher Hahn.

Additional co-authors on the paper include Chansol Kim, Sydney Hemenway, Junho Park, Anya Zoraster, Calton Kong, Rajiv Ramanujam Prabhakar and Joel Ager from Lawrence Berkeley National Laboratory and UC Berkeley, Joel Varley from LLNL, and Hee-Tae Jung from KAIST.

The research is funded as part of the Center for Closing the Carbon Cycle, an Energy Frontier Research Center, and the Clean Energy Manufacturing Program, both funded by the U.S. Department of Energy, Office of Science, Basic Energy Sciences.

Contact

Anne M. Stark

Anne M. Stark

[email protected]

(925) 422-9799

Related Links

Importance of Site Diversity and Connectivity in Electrochemical CO Reduction on CuTags

Physical and Life SciencesMaterials Science

Featured Articles