New technique converts excess renewable energy to natural gas

(Download Image)

(Download Image)

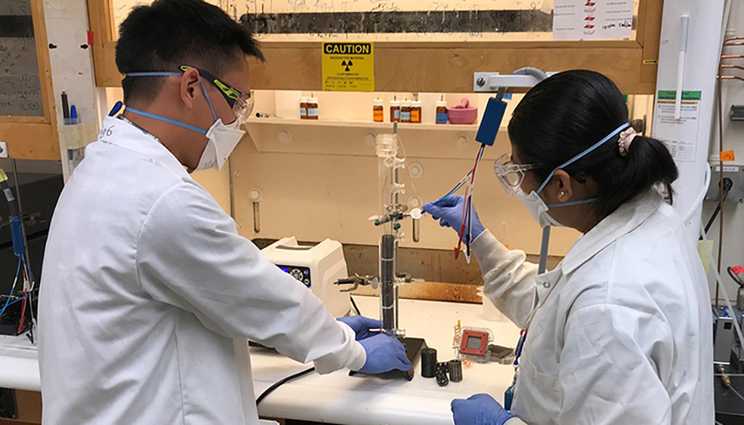

Simon Pang (left) and Buddhinie Jayathilake assemble and prepare a prototype bubble column electrobioreactor to test additively manufactured three-dimensional electrodes. Under their project, excess renewable electricity from wind and solar sources would be stored in chemical bonds as renewable natural gas. (Photo: Nathan Ellebracht)

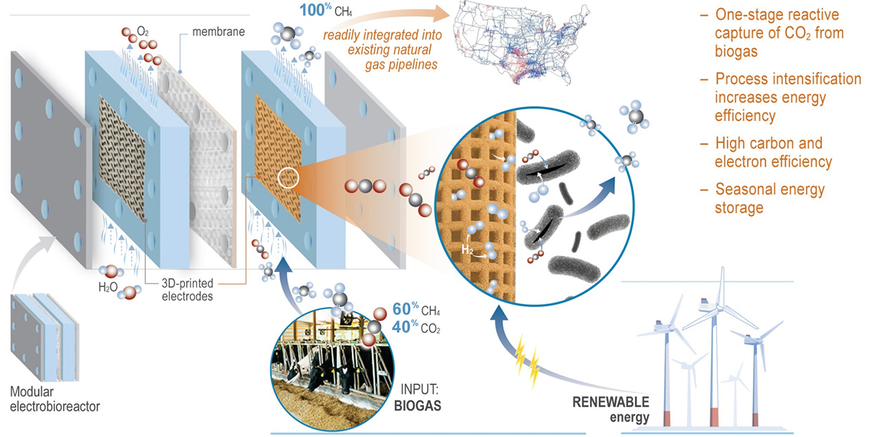

Four Lawrence Livermore National Laboratory (LLNL) researchers have partnered with Los Angeles-based SoCalGas and Munich, Germany-based Electrochaea to develop an electrobioreactor to allow excess renewable electricity from wind and solar sources to be stored in chemical bonds as renewable natural gas.

When renewable electricity supply exceeds demand, electric-utility operators intentionally curtail production of renewable electricity to avoid overloading the grid. In 2020, in California, more than 1.5 million megawatt hours of renewable electricity were curtailed, enough to power more than 100,000 households for a full year.

This practice also occurs in other countries. The team’s electrobioreactor uses the renewable electricity to convert water into hydrogen and oxygen. The microbes then use the hydrogen to convert carbon dioxide into methane, which is a major component of natural gas. Methane can then be moved around in natural gas pipelines and can be stored indefinitely, allowing the renewable energy to be recovered when it is most needed.

“This technology will help enable decarbonization of the natural gas grid infrastructure by providing a renewable source of natural gas,” said Simon Pang, a materials scientist in the Lab’s Materials Science Division who heads the LLNL portion of the project. “This renewable natural gas can be moved and used in existing infrastructure, allowing the technology to be deployed soon to meet green-energy demand. Moreover, by producing pipeline-quality renewable natural gas from biogas, we can increase the value of biogas and reduce the likelihood that it will be vented to the atmosphere, reducing greenhouse gas emissions and improving local air quality.”

The technology is based in LLNL’s expertise in engineering of flow electrochemical devices and additive manufacturing of electrolyzer components. In particular, this project leverages LLNL’s expertise in 3D printing of electrically-conductive components (electrodes) that increase the surface area and mixing of the liquid to improve the energy efficiency of the device.

“The development of our electrobioreactor would be an advance over the state-of-the-art technology, which uses a separate electrolyzer to produce hydrogen and bioreactor to perform the conversion,” Pang said. “By integrating the electrolyzer and bioreactor together into a single device, we think we can achieve higher energy efficiency and performance in a compact device that will allow production of pipeline-quality renewable natural gas directly from biogas and renewable electricity.”

Other LLNL researchers on the project include Buddhinie Jayathilake, Laura Gutierrez and Melinda Jue.

The work is funded with $1 million from the Technology Commercialization Fund of the DOE Industrial Efficiency and Decarbonization Office, a division of the Office of Energy Efficiency and Renewable Energy. Partners will provide $1 million in in-kind contributions or research funds.

Contact

Anne M. Stark

Anne M. Stark

[email protected]

(925) 422-9799

Related Links

SoCalGasElectrochaea

Industrial Efficiency and Decarbonization Office

Tags

Earth and Atmospheric ScienceEnergy

Physical and Life Sciences

Economic Impact

Industry Collaborations

Materials Science

Featured Articles