Just add salt: Researchers explore a new electricity-free cooling method

(Download Image)

(Download Image)

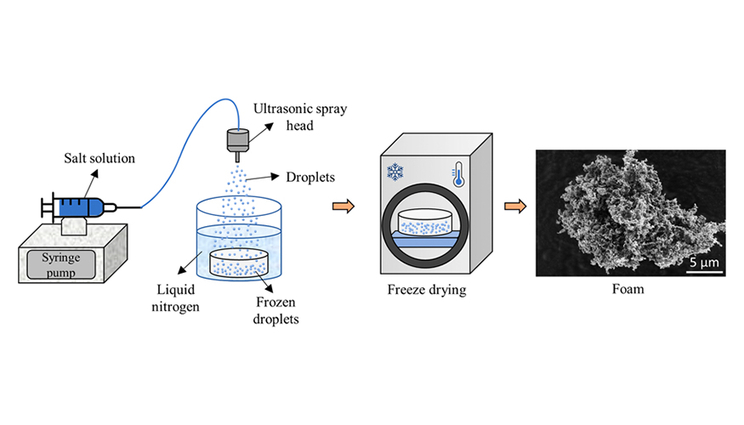

A schematic illustration of the salt foam fabrication process that a Lawrence Livermore research team used to transform sodium chloride (table salt) and potassium chloride into foams that could then be packed into a panel and used to provide 24-hour, electricity-free cooling.

Rising global temperatures are creating an increased demand for cooling as the number of air-conditioning units used worldwide is expected to triple by 2050. However, with 13% of the global population without access to electricity, solutions that can provide cooling without electricity are needed.

In a study published in Materials Horizon, a Lawrence Livermore National Laboratory (LLNL) research team explores a passive daytime radiative cooling (PDRC) method using sodium chloride (table salt) and potassium chloride to fabricate a panel that can provide 24-hour, electricity-free cooling. PDRC is an environmentally friendly supplement to air-conditioning that can reduce buildings’ energy usage, increase power plant efficiency, collect water from the air and even desalinate water.

The project’s lead scientist John Roehling has been conceptualizing this technology for more than a decade — even before he came to LLNL. He said: “The LDRD [Laboratory Directed Research and Development] program allowed me to take something that is near and dear to me and turn it into a technology that can actually have an impact in the world. I think the fact that these kinds of opportunities exist is one of the best features of working here.”

To bring Roehling’s idea to life, sodium chloride (NaCl) and potassium chloride (KCl) were used, as these materials are naturally abundant and highly infrared-transparent, making them ideal for insulating a cooling surface while allowing infrared heat to escape. Previous work has shown that salts can be fabricated into foams using flash freezing and freeze drying. Freeze drying is an industrially used process, easily scaled and currently used for food and drug production.

The team fabricated NaCl and KCl into aerogel-like foam structures capable of scattering (reflecting) visible light, transmitting infrared radiation (IR), and providing thermal insulation. These loose foams were packaged into salt foam panels (SFP) with a supporting mechanical frame to minimize mechanical damage.

The microstructure and feature size of the salt foams were controlled by changing the salt concentration, salt composition and solution additives to achieve the properties necessary for radiative cooling. The tunable feature size of the foam provided an opportunity to optimize for high optical reflectivity, while maintaining high IR transmission, and the porous structure of the foam provided low thermal conductivity to minimize parasitic heat transfer.

The panels were tested near Livermore on one of the hottest days of the year, with the ambient temperature peaking at 42°C (107.6°F). A full 24-hour cycle was measured to demonstrate the uninterrupted cooling capabilities of the SFP. The results show the panels were able to keep an underlying surface below ambient temperature by up to 10 °C (18°F), reducing heat loss to the surrounding air by more than half (compared to an uncovered surface).

Overall, these salt foam panels are scalable, easily transferable from surfaces (important in cold months when passive cooling increases energy use) and economically viable, making them an ideal alternative or addition to other state-of-the-art PDRC devices. The team’s design also allows the cooling panel to be easily placed and removed without complex installation for seasons when cooling is not desired — other radiative cooling materials are often non-removable.

“Investigating innovative and accessible solutions for global issues has always been important to me," said research scientist Mariana Reale Batista. “I am grateful to be part of this team and I am thrilled that our research has the potential to impact the global community, particularly those in hot climates without access to electricity. I am hopeful that this affordable cooling technology will save many lives.”

Next, the team will work on additional optimizations that could improve the material function further. This includes improving freezing to produce smaller foam-feature sizes (because feature size decreases with increasing freeze rate). This will increase the IR transmission (allowing the maximum amount of heat to escape) of the foam and allow thicker devices to be produced, improving insulating power and ultimately making the material capable of achieving lower stagnation temperatures and higher cooling powers.

Other LLNL authors on the paper include Alyssa Troksa, Hannah Eshelman and Michael Bagge-Hansen.

–Shelby Conn

Contact

Anne M. Stark

Anne M. Stark

[email protected]

(925) 422-9799

Related Links

Materials HorizonLaboratory Directed Research Development

Tags

Physical and Life SciencesMaterials Science

Featured Articles