Back

Lawrence Livermore National Laboratory (LLNL) researchers have published a precise computer model of a deposition process using electrically charged particles that will provide scientists and engineers with unprecedented insights into the method.The process of electrophoretic deposition (EPD) uses an electric field to drive colloidal particles suspended in a liquid from a…

For three Lab engineers, a Lawrence Livermore National Laboratory (LLNL) commercialization fund has proven to be an oasis of assistance as they have sought to cross the legendary technology "valley of death."In technology transfer circles, there is a phase -- between when a technology is promising and when it moves forward into commercialization -- known as the "valley of…

Looking to ramp up hiring of engineers and extend its reach into the country’s top engineering schools, Lawrence Livermore National Laboratory (LLNL) is launching an internship program with Texas A&M University (TAMU) that will bring promising engineering students to the Lab starting this summer. If selected, up to two TAMU (undergraduate, junior or senior) students…

The Defense Advanced Research Projects Agency (DARPA) named Lawrence Livermore National Laboratory engineer and physicist Vincent Tang as a Program Manager of the Year for 2016, recognizing him for leading a program involving multiple agencies to develop and deploy networked sensors for dynamic, real-time radiological and nuclear threat detection over large urban areas…

Lawrence Livermore National Laboratory and National Nuclear Security Administration (NNSA) officials, along with representatives from local government and industry, broke ground Friday on the Advanced Manufacturing Lab (AML), a modern collaborative hub for developing next-generation materials and manufacturing technologies.The $9.4 million, 13,000-square-foot facility will…

Lawrence Livermore National Laboratory researchers have garnered three awards among the top 100 industrial inventions worldwide for 2016. The trade journal R&D Magazine announced the winners of its annual awards, sometimes called the "Oscars of invention," Thursday at the Gaylord Convention Center in Washington, D.C. With this year’s results, the Laboratory has now…

As hydrogen fuel cell cars become commercially available and hydrogen refueling stations slowly begin to proliferate throughout California, government agencies are turning to Lawrence Livermore National Laboratory to help detect leaks that could lead to fire. The South Coast Air Quality Management District (SCAQMD), the air pollution control agency for Orange County and…

Members of Lawrence Livermore National Laboratory’s Additive Manufacturing Initiative are among a group of researchers who have developed 3D printed materials with a unique property -- instead of expanding when heated, they shrink. In a study published in the Oct. 21 edition of the journal Physical Review Letters, LLNL engineers, along with scientists from the University…

Advanced 3D printing promises to redefine manufacturing in critical industries such as aerospace, transportation and defense, and now, Lawrence Livermore National Laboratory is exploring the use of 3D printing to achieve unprecedented flexibility in producing "on-demand" targets for testing how materials behave under extreme conditions. Through an additive manufacturing…

The "valley of death" can make or break a startup enterprise due to the cost and time involved in getting from prototype to profitability. To help clean technology entrepreneurs and engineers navigate across the chasm and make it safely to the other side, the Department of Energy’s (DOE’s) Office of Energy Efficiency & Renewable Energy (EERE) has announced the…

Lawrence Livermore National Laboratory (LLNL) engineers have achieved unprecedented scalability in 3D-printed architectures of arbitrary geometry, opening the door to super-strong, ultra-lightweight and flexible metallic materials for aerospace, the military and the automotive industry. In a study published online July 18 in Nature Materials, LLNL engineers report building…

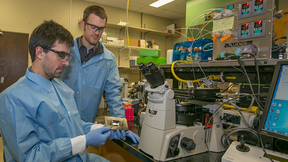

LLNL researchers are exploring the use of metal 3D printing to create strong, lightweight structures for advanced laser systems - an effort they say could alter the way lasers are designed in the future. In a Laboratory Directed Research and Development (LDRD) program, physicist Ibo Matthews and his team are experimenting with a new research-based metal 3D printer, one of…

While he was working as a machinist in Oakland and taking classes at Laney College, Wesley Scoggins wanted to improve his skills to find a better job. In 2012, he answered a Craigslist posting for a slot in the Livermore Lab Engineering Directorate’s Machinist Apprentice Program. It was an opportunity he couldn’t pass up. "It’s really one of the only machinist…

The Department of Energy (DOE) recently announced the selection of two proposals from Lawrence Livermore National Laboratory (LLNL) researchers for grants under the department’s Technology Commercialization Fund (TCF), a program intended to help promising energy technologies move from national laboratories to the marketplace. DOE awarded LLNL engineer Brian Guidry a $432…

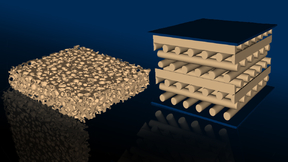

Through a series of dynamic compression experiments on additively manufactured (AM) structured lattices, a Lawrence Livermore National Laboratory team, supported by colleagues at Los Alamos National Laboratory, has found that the assemblies have unique properties not exhibited by disordered cellular materials. During the experiment, elastic deflection of the structure…

When Daryl Boyer was asked to lend his technical expertise to help shape the future of the U.S. nuclear deterrent, he knew it meant relocating to Omaha, Nebraska, without his parents and children. But the challenge called him and the timing was right. He acted decisively. Boyer is an LLNL engineer on assignment to the Global Strike Capabilities Division of the U.S…

Lawrence Livermore National Laboratory (LLNL) researchers, along with a team from UC Santa Cruz (UCSC), have devised a method for doubling the performance of 3D-printed graphene-based supercapacitors. The method, which involves sandwiching lithium ion and perchlorate ion between layers of graphene in aerogel electrodes, substantially improved the capacity of the electrodes…

Development of new prescription drugs and antidotes to toxins currently relies extensively on animal testing in the early stages of development, which is not only expensive and time consuming, it can give scientists inaccurate data about how humans will respond to such agents. But what if researchers could predict the impacts of potentially harmful chemicals, viruses or…

Researchers at Lawrence Livermore National Laboratory (LLNL) have taken a major step toward answering a question plaguing a common metal 3-D printing technique: What interactions can lead to the porosity found in parts produced by laser powder-bed fusion processes? In a paper published in the May 20 edition of the journal Acta Materialia online, LLNL researcher Ibo…

Lawrence Livermore National Laboratory (LLNL) material scientists have found that 3D-printed foam works better than standard cellular materials in terms of durability and long-term mechanical performance.Foams, also known as cellular solids, are an important class of materials with applications ranging from thermal insulation and shock-absorbing support cushions to…