New class of 3D-printed alloys brings more flexibility to super-strong metal parts

(Download Image)

(Download Image)

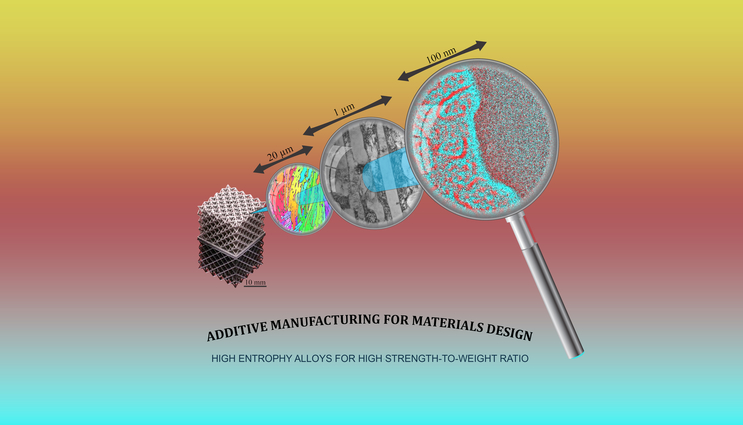

Researchers at Lawrence Livermore National Laboratory, Oak Ridge National Laboratory and several universities used a common laser-based metal 3D printing method to produce a new class of high entropy alloys that demonstrated both high yield strength and high ductility beyond other state-of-the-art 3D printed metal alloys. The team also built lattice structures and other engineering components from the material, proving the viability of the technique. Image courtesy of UMass Amherst.

Metal 3D printing is used to produce components for many commercial applications, particularly in the transportation sector, where printing methods such as laser powder bed fusion (L-PBF) can produce super-strong and ultralight complex-shaped components that cannot be manufactured with conventional techniques.

But while laser-based methods enable the manufacturing of materials that can achieve high strength, these materials often suffer from fragility — breaking instead of deforming plastically — thus limiting their use in structural applications where high strength is critical.

Recent classes of metallic alloys — high-entropy alloys (HEA) or multi-principal elements alloys (MPEAs) — are allowing materials scientists to investigate a vaster space of compositions to further develop the next generation of alloys. The work has allowed scientists to make materials that are composed of two different main phases — one giving the materials strength, the other ductility. Distributing these different phases finely and homogenously are key to increasing the strength while limiting the loss in ductility, according to researchers.

Seeking the best of both worlds, a materials scientist at Lawrence Livermore National Laboratory, along with researchers at numerous universities and Oak Ridge National Laboratory (ORNL), have used the L-PBF method to produce a class of eutectic HEAs (EHEAs) demonstrating both high-yield strength and high ductility, beyond other state-of-the-art 3D printed metal alloys. The team also built lattice structures and other engineering components from the material, proving the viability of the technique. The work appears online in the journal Nature.

Researchers said the insights gained into the strengthening behavior of eutectic HEAs could have broad implications for the development of additive manufactured (AM) hierarchical nanostructured alloys with exceptional mechanical properties, such as aluminum and titanium alloys.

“We have combined HEAs and AM to produce a material that not only exhibits the right phases, but also contains a refined and homogeneous microstructure, unlike anything that can be achieved with conventional manufacturing processes,” said co-author and LLNL scientist Thomas Voisin. “We were able to obtain a stronger material that still offers an acceptable ductility compared to the same material processed with conventional techniques. And we were able to explain the mechanisms associated with this enhancement combining state-of-the-art experiments and simulations, opening the door to further improvements. What we are showing with this paper is that AM needs to be seen as more than just a manufacturing tool.”

Voisin, along with co-authors from the University of Massachusetts, Amherst and several other universities, said the technique allows them to retain non-equilibrium states of materials by locally melting and very rapidly cooling the material, unlike what can be achieved with any other technique.

Wen Chen, a former LLNL postdoc and current assistant professor at the University of Massachusetts Amherst, designed and led the study.

“This unusual microstructure’s atomic rearrangement gives rise to enhanced strength as well as enhanced ductility, which is uncommon because usually, strong materials tend to be brittle,” Chen said. “We got almost triple the strength (beyond conventional metals) and not only didn’t lose ductility, but actually increased it simultaneously. For many applications, a combination of strength and ductility is key. Our findings are original and exciting for materials science and engineering alike.”

Using a commercially available LBPF printer, the team printed a variety of components, including a heatsink fan, an octet-truss micro-lattice and a gear, and tested the pieces mechanically, chemically and through neutron diffraction tensile tests performed at ORNL. LLNL scientists performed transmission electron microscopy to help understand the underlying mechanisms associated with the mechanical properties’ improvement and thermal stability of the material.

“By changing the local temperature and cooling rates during additive manufacturing (AM), we can change material’s properties,” Voisin said. “From a materials science point of view, this is really where the revolution with additive manufacturing lies. The fact that AM can also make complex near-net shape components is the cherry on the cake.”

According to the team, the as-processed material achieved high-yield strength of about 1.3 gigapascals and a large tensile ductility (a uniform elongation of about 14 percent), the result of their alternating dual-phase nanostructures.

Lead author Jie Ren, a Ph.D. student in mechanical and industrial engineering at UMass Amherst, said the results could impact future applications of 3D-printed metal alloys in the commercial sector.

“The ability to produce strong and ductile HEAs means that the materials are more robust in resisting applied deformation, which is important for lightweight structural design for enhanced mechanical efficiency and energy saving,” Ren said.

Co-authors include former LLNL materials scientist Morris Wang, now a professor at the University of California, Los Angeles, and researchers from the Georgia Institute of Technology, Texas A&M University and Rice University.

Contact

Jeremy Thomas

Jeremy Thomas

[email protected]

(925) 422-5539

Related Links

NatureTags

Advanced Materials and ManufacturingMaterials Science

HPC, Simulation, and Data Science

Computing

Engineering

Physical and Life Sciences

Featured Articles