Beating the odds: Former Energetic Materials Center intern named U.S. Air Force Cadet of the Year

(Download Image)

(Download Image)

Lieutenant Hannah Fletcher closing the canopy of a United States Air Force T-6 Texan II before takeoff at Columbus Air Force Base.

Second Lt. Hannah Fletcher, a 2021 Lawrence Livermore National Laboratory (LLNL) Reserve Officer Training Corps (ROTC) summer intern, has been named the 2022 United States Air Force (USAF) Cadet of the Year. This award recognizes the best cadet in an Air Force commissioning program based on military performance, academics and physical fitness.

LLNL’s ROTC internship program reinforces the commitment that the national laboratories have to the Department of Defense and the importance of providing hands-on research and development (R&D) experience to the nation’s future military leaders.

A graduate from North Carolina (NC) State University, Fletcher double majored in international relations and mechanical engineering and minored in Chinese. At NC State, she was the cadet wing commander for Detachment 595 — leading the university’s estimated 100 ROTC cadets. In August 2021, while awaiting her post-graduation active-duty assignment, Fletcher came to Livermore and worked with staff scientists in the Energetic Materials Center (EMC) to improve the additive manufacturing techniques used to create weapons.

An unlikely solution

During her internship, Fletcher contributed to Project DarkStar, an ongoing Laboratory Directed Research Development (LDRD) initiative led by LLNL scientist Jon Belof. This project, a collaboration with the Colorado School of Mines, aims to control material deformation, enabling a completely new paradigm for weapons physics and design and advancing the U.S. national security posture.

“Prior to working with real energetic materials, scientists conduct 3D printing tests using inert surrogates as practice materials,” said Fletcher’s mentor and co-lead of the project Dylan Kline

With Fletcher’s assistance, the DarkStar team was able to improve their direct ink writing (DIW) 3D printing process — a manufacturing technique in which a viscous material is extruded through a moving nozzle at a prescribed rate. Fletcher’s fresh perspectives helped the team realize they needed a better formulation that was more representative of the materials they were interested in 3D printing, as well as something that was easier to clean out of the 3D printer after running the experiment.

After some brainstorming, Fletcher and Kline jokingly suggested they try to use cake frosting as the test material. This seemingly whimsical idea ultimately led the team to finding an ideal frosting-based formulation that enabled them to quickly make inert surrogates with tunable rheological (flow) properties. With this approach, the researchers could then evaluate how these rheological properties are related to printing parameters, examine how the material extrudes from the printer’s nozzle and print more effectively as a result.

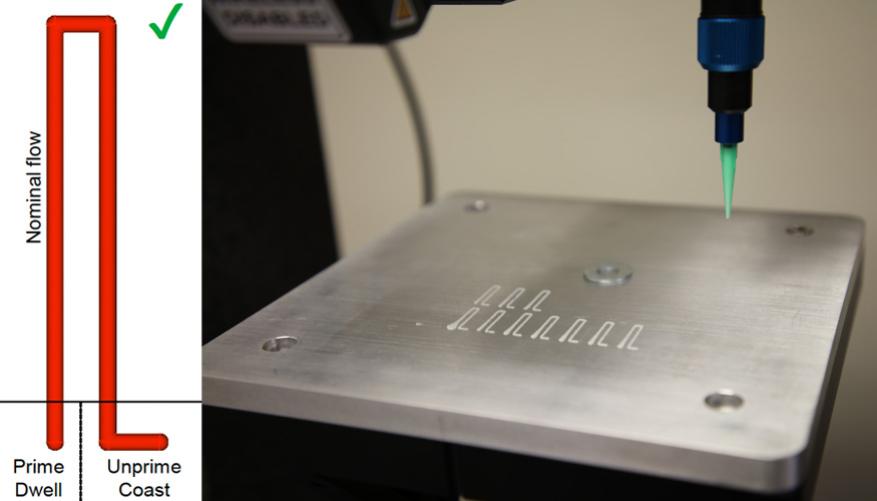

(Left) Example of a successful printing flow. (Right) A 3D printer calibration test using the frosting-based formulation.The bigger picture

In addition to the formulation work, the team demonstrated a layer-by-layer, laser profilometry-based in situ characterization technique to digitally reconstruct a multi-material part. This method, described in an article for the journal Additive Manufacturing, sets the stage for real-time process monitoring and paves the way for additively manufactured parts that are “born qualified” — that is, ensuring a part’s functionality during the manufacturing process without needing additional testing.

The team’s approach combines traditional machine vision — an image-based inspection method widely employed across industries for process monitoring and part qualification — with profilometry to generate a height map and grayscale intensity map of each printed layer. The height map clearly discriminates between regions where new material has been deposited and where it is absent, while the grayscale intensity map allows discrimination between visually dissimilar regions. These in situ data collection techniques allowed the team to digitally reconstruct the printed part and identify features that were only optically accessible during fabrication.

“If 3D printing was like stacking bricks, this technique would be like taking a bird’s eye view photo of each brick layer, identifying where new bricks were added, and then using only that information to create a digital version of the larger structure,” Kline said. “Each individual layer of new bricks does not really describe the structure being made, but when you stack the bricks, you can clearly see the whole structure — the good and the bad.”

Looking ahead, any data collected and analyzed in real time could be used to inform a “go/no go” control program and therefore stop a process if it deviates too much from the desired toolpath. Another potential application of this technique could be real-time defect correction based on information gathered by the sensor.

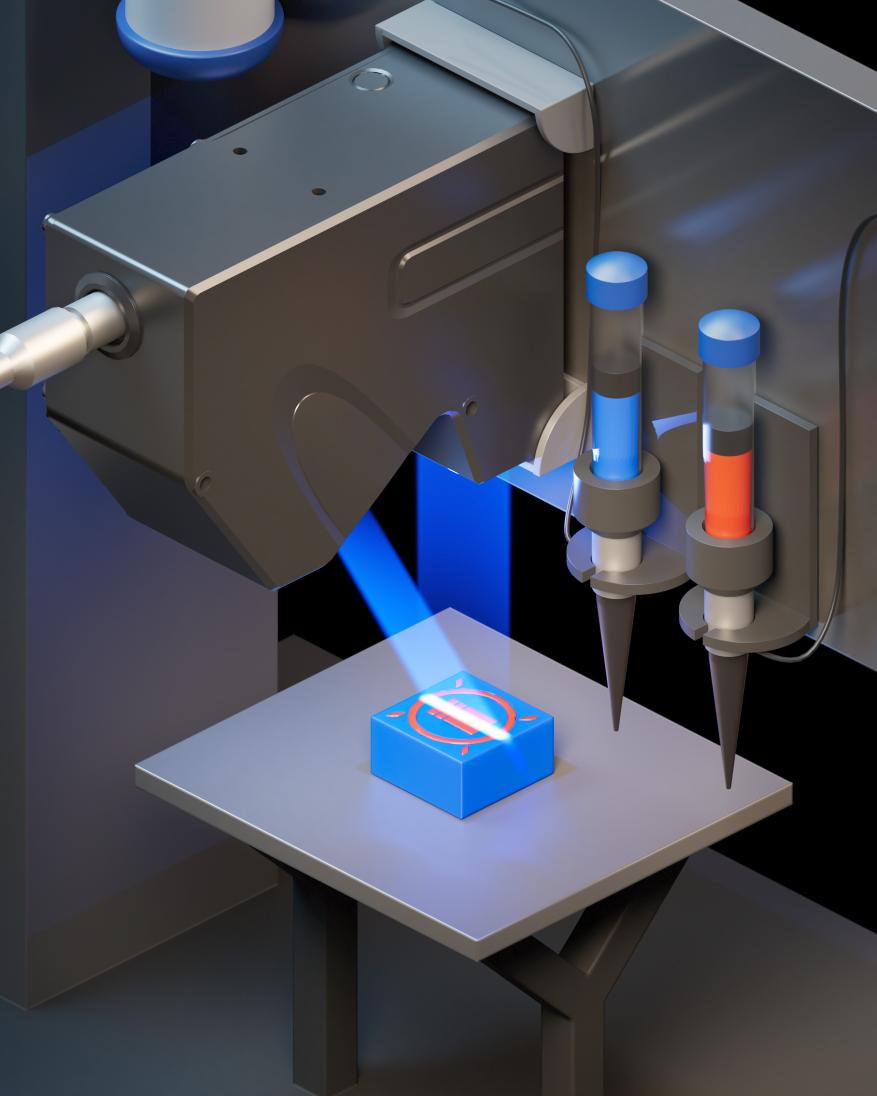

An artistic representation of the laser profilometer, which is mounted to the printer and used to scan the top layer of a printed test object. Image by Brendan Thompson.

When ROTC meets R&D

“Having Hannah helped us reframe our approach and provided us with new and interesting ideas,” Kline said. “Not only did she help improve LLNL’s additive manufacturing processes for energetic materials, but she also provided the team with valuable insights regarding the most effective way to train someone to operate the Lab’s 3D printing equipment.”

Kline expressed: “We’re a weapons lab, we support the military, and these students that come here are not just protected by the tools that we develop but they are the users — they are invested in them, and these are the people who should be learning about what we are doing. By working together, we can improve everybody’s safety, enable a wider mission space, establish better connections, and enhance the stockpile.”

Fletcher added: “If we can teach those early in their career the problems that our nation faces and show them what R&D looks like up close through ROTC-specific internships, then we can better support our nuclear mission.”

When hearing the news of Fletcher’s USAF award, Belof said: “We were all very impressed with Hannah during her brief stay at Livermore and with her work on Project DarkStar. Her accomplishments outside of the Lab are just as impressive and impactful. No doubt, our country is in good hands with talented future leaders like Lt. Fletcher.”

As a word of advice to future LLNL interns, Fletcher said: “Come with an open mind, be ready to meet the smartest people you have ever encountered, make an effort to learn something new every day and have a [literal] blast.”

–Shelby Conn

Contact

Anne M. Stark

Anne M. Stark

[email protected]

(925) 422-9799

Related Links

Project DarkStarNorth Carolina (NC) State University

Tags

Energetic Materials CenterAdvanced Materials and Manufacturing

Materials Science

People

Academic Engagement

Students

Physical and Life Sciences

Careers

Community Outreach

Featured Articles