In a first, LLNL researchers create birefringent all-glass metasurface

(Download Image)

(Download Image)

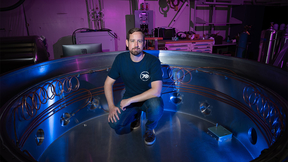

Nathan Ray and Hoang Nguyen used this etcher to create tilted pillars in an all-glass metasurface, giving the material birefringent properties. Photo by Jason Laurea

Lawrence Livermore National Laboratory (LLNL) researchers have adapted their novel metasurface process, which creates a thin layer on the surface of an optic, to create an all-glass metasurface with birefringence, or dual refraction, properties. This achievement could transform waveplate technology for high-power laser systems such as the National Ignition Facility (NIF).

The result is reported in a new paper, “Birefringent Glass-Engraved Tilted Pillar Metasurfaces for High Power Laser Applications,” which was a featured story in the August 2023 issue of Advanced Science.

“This is the first demonstration, to the best of our knowledge, of an etching technique to obtain the resulting tilted pillar-like nanofeatures which will generate birefringence,” said LLNL staff scientist Nathan Ray, first author of the paper.

Birefringence is a phenomenon in which light propagates at a different speed depending on the light polarization direction, the result of optical anisotropy (showing different properties in different directions) of the index of refraction. As a result, when light enters a birefringent material in such a way that it has components in the two principal polarization planes, the light polarization state could change and be transformed from a linear polarization to a circular one.

In laser systems, this quality is used to control attenuation of the laser’s energy without introducing absorption by sandwiching a waveplate between two polarizers. Birefringence is an important quality for high-power laser systems, but materials with inherent birefringence are not always durable enough to withstand high fluences (energy per unit area). Traditional birefringent materials are used in lower-energy applications like polarization microscopy and optical isolators.

“While waveplates of birefringent materials could have a critical role in reducing laser-induced damage inside optics of a high-power laser system like the NIF, it is a major challenge to find such durable and scalable technology,” said LLNL staff scientist Eyal Feigenbaum, the principal investigator. “The approach that we have developed is size-scalable and results in nano-scale features that are etched into the fused silica glass itself for durability. We are modifying a layer of glass that is not birefringent to become birefringent.”

In a Laboratory Directed Research and Development (LDRD) project, the researchers set out to use a novel metasurface process already proven for creating optical features of interest for reducing reflection to make an all-glass metasurface with birefringence properties.

Metasurface is an approach to optics design in which the surface of a material is carefully altered, creating an ultrathin layer with properties that differ from those within the bulk of the material. This is done by introducing features smaller than the optical wavelength. Feigenbaum’s team has been developing a scalable process for engraving metasurfaces into fused silica glass, part of series of LDRD projects ending this year.

Their basic four-step process, consisting of ultrathin metal film deposition, dewetting, etching and mask removal, results in an all-glass metasurface. While relatively simple, the process provides substantial tunability and control over metasurface features.

To create birefringence, the team etched tilted pillars at a 50-degree angle to break the symmetry of the light as it enters the material. This allows light with different propagation to observe different properties. In previous projects, the pillars were etched perpendicular to the surface.

“To achieve the birefringence necessary for an effective waveplate, we need to tilt the metasurface nano-pillars so they are substantially angled with respect to the surface,” Ray said. “The models show that getting a larger birefringence than the one experimentally demonstrated is possible. We’ve identified several approaches, but it will take some trial and error. When you change one process parameter, you don’t know how it will affect the rest of the process until you try.”

Those approaches are to make the pillars longer, optimize their density and tilt angle and reduce the spacing between pillars. The team is currently working on increasing the birefringence, as well as developing other approaches.

In testing the birefringent metasurface, the researchers discovered that they also made the surface anisotropic for additional surface properties. The angled features of the metasurface can either halt or allow the movement of fluid, depending on the intended direction of the flow with respect to the tilt direction of the nano-pillars.

“This quality opens up new application space,” Ray said.

The imparted anisotropy along with advancements the team made towards spatially patterning these types of metasurfaces lends itself to potential manipulation of water flow steering capabilities.

Joining Ray and Feigenbaum on the paper were fellow LLNL scientists Hoang Nguyen, Jae-Hyuck (Jake) Yoo and Michael Johnson.

Contact

Patricia Koning

Patricia Koning

[email protected]

(925) 423-4332

Related Links

Birefringent Glass-Engraved Tilted Pillar MetasurfacesLaboratory Directed Research and Development

Optical features of interest

Tags

Advanced Materials and ManufacturingLasers and Optical S&T

National Ignition Facility and Photon Science

Physical and Life Sciences

Lasers

Materials Science

Physics

Science

Featured Articles