Designing materials for high-temperature structural applications

(Download Image)

(Download Image)

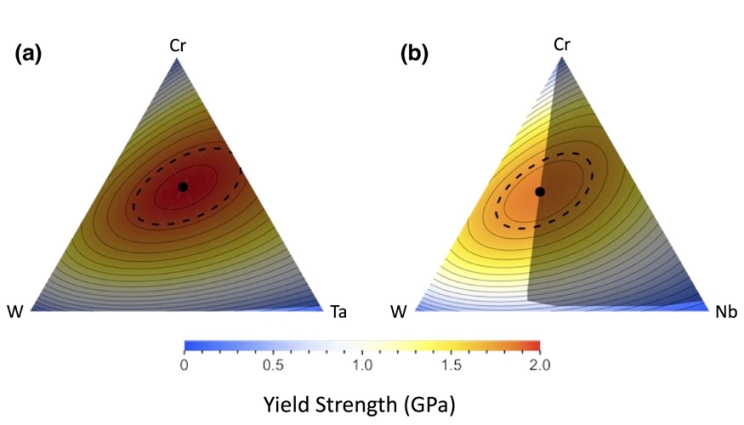

As a first step to narrow the search space, researchers consider the behavior of all 165 ternary systems at 1300 and 1800 kelvin. As an example, the yield strength and phase stability information for the ternary systems Cr-Ta-W and Cr-Nb-W at 1300 K are shown in the figure, respectively. The semi-transparent gray overlay indicates regions where the fraction of body-centered cubic phase stability is less than 100%.

A materials science team, led by postdoctoral researcher Kate Elder, recently published a two-part series in npj Computational Materials. The research focuses on the computational discovery of ultra-strong, stable, and lightweight refractory metal-based multi-principal element alloys (MPEAs), which are compelling materials for high-temperature structural applications. MPEAs based on refractory elements with high melting points can maintain high strength at elevated temperatures, making them promising candidates for applications in aerospace and hypersonics.

Conventional alloys typically have one principal element with small amounts of other elements added to improve material properties. A common example is steel, which contains ~98% iron with small amounts of carbon, manganese, and various other elements. MPEAs consist of two or more principal elements and may contain non-principal elements. While conventional alloys have existed for centuries, MPEAs only just emerged in 2004. Over the last 20 years, the volume of literature surrounding MPEAs has increased exponentially. Still, this vast design space has not been fully explored, and efficient and accurate down-screening procedures are needed to discover alloys optimized for specific applications.

One major challenge in the study of these alloys is the relative difficulty of synthesizing and mechanically testing them at high temperatures. However, without computational predictions, many elemental compositions remain unexplored. Scientists believe that is highly likely that a combination of sufficiently accurate models would enable the discovery of many alloys with significantly higher strengths at elevated temperatures.

While part one of the study computationally explored a large region of the design space of an 11-element family (Al-Cr-Fe-Hf-Mo-Nb-Ta-Ti-V-W-Zr), part two focused on ternary design possibilities (a combination of three elements) and experimentally validated the theoretical predictions. In part one, researchers proposed and applied two modeling approaches to explore a large part of the previously underexplored design space, with the goals of optimizing yield strength (YS), specific yield strength (SYS), and body-centered cubic (BCC) phase stability—as non-BCC phases are known to induce detrimental brittleness. YS measures a material’s limit before it begins to deform and break down, SYS is a measure of strength equivalent to yield strength divided by material density, and BCC refers to the structure of the elemental composition where a cell has an atom at each of the eight corners of a cube and an atom in the center of the cube.

Compared to part one, part two pursued a more constrained and application-relevant design space, narrowing down the original 165 possible ternary systems to 13 high-performing ternary systems whose composition space is then further explored to find optimized alloys. Overall, the top ternary systems identified in parts one and two are quite similar, with clear and identifiable reasons for any differences. Further experimental and computational work is still needed to confirm the predicted high-temperature strengths of the alloys, examine the appearance of other phases at lower temperatures, assess the stability of the recommended metastable alloys, and ensure sufficient ductility.

This work was supported by LLNL’s Laboratory Directed Research and Development program (22-SI-007).

[K.L.M. Elder, J. Berry, A. Perron, B. Bocklund, J. Shittu, C.J. Rietema, H.B. Henderson, S.K. McCall, J.T. McKeown, Computational discovery of ultra-strong, stable, and lightweight refractory multi-principal element alloys. Part II: comprehensive ternary design and validation, npj Computational (2023), DOI: 10.1038/s41524-023-01031-6.]

[K.L.M. Elder, J. Berry, B. Bocklund, S.K. McCall, A. Perron, J.T. McKeown, Computational discovery of ultra-strong, stable, and lightweight refractory multi-principal element alloys. Part I: design principles and rapid down-selection, npj Computational (2023), DOI: 10.1038/s41524-023-01030-7.]

–Physical and Life Sciences Communications Team

Tags

Advanced Materials and ManufacturingMaterials Science

Physical and Life Sciences

Featured Articles