Machine-learning model instantly predicts polymer properties

(Download Image)

(Download Image)

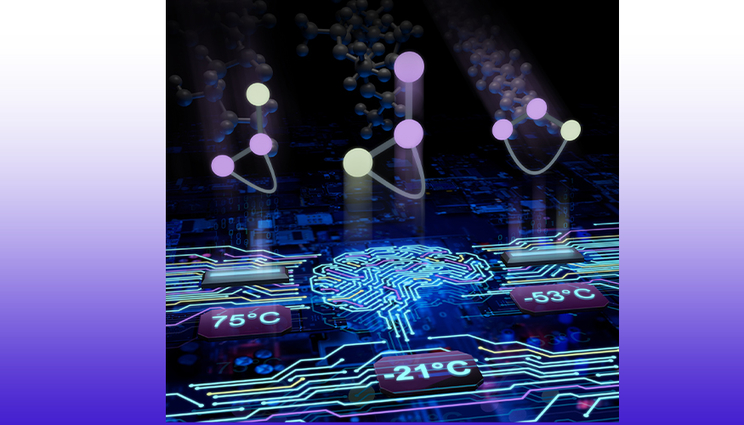

An artist’s rendering shows how polymers can be represented as graphs for the machine-learning model and how subtle changes in polymers’ connectivity and periodicity can have dramatic effects on their predicted properties; in this case, glass-transition temperature. Image by Eric Smith/LLNL.

Hundreds of millions of tons of polymer materials are produced globally for use in a vast and ever-growing application space with new material demands such as green chemistry polymers, consumer packaging, adhesives, automotive components, fabrics and solar cells.

But discovering suitable polymer materials for use in these applications lies in accurately predicting the properties that a candidate material will have. Obtaining a quantitative understanding of the relationship between chemical structure and observable properties is particularly challenging for polymers, due to their complex 3D chemical assembly that can consist of extremely long chains of thousands of atoms.

Recently, a team of Lawrence Livermore National Laboratory (LLNL) materials and computer scientists tackled this challenge with a data-driven approach. By using datasets of polymer properties, the researchers developed a novel machine-learning (ML) model that can predict 10 distinct polymer properties more accurately than was possible with previous ML models.

“The secret to the success of the new ML model lies in a new polymer representation that compactly captures the polymers’ structure, in combination with powerful graph-based machine-learning techniques that autonomously learn how to best describe the structure of the polymer,” said LLNL postdoc Evan Antoniuk, lead author of a paper appearing in the Journal of Chemical Information and Modeling.

The chemical structure of polymers is typically made up of between tens or thousands of repeating chemical subunits, a characteristic that is called periodicity. Previous approaches to predicting polymer properties with ML could not capture this extended periodic polymer structure, leading to inaccurate predictions.

In this work, the research team developed a new method for explicitly encoding the polymer’s periodicity into the ML model.

“The results of this work show that the inclusion of periodicity in the ML model gives rise to state-of-the-art accuracy for predicting polymer properties,” Antoniuk said.

In a chemical laboratory, it often takes a long time to synthesize and characterize new polymers before being able to perform measurements to obtain their properties. But the ML model is able to generate property predictions nearly immediately. The research team is currently working with LLNL developer Joe Chavez to create an interactive web interface to allow the ML models to be accessible to anyone.

“This interactive model will allow polymer chemists to instantaneously gain an understanding of the properties of new polymer materials, allowing for new concepts in polymer chemistry to be rapidly tested and iterated upon,” said LLNL scientist and co-author Anna Hiszpanski.

Other LLNL scientists involved in the research include Peggy Li and Bhavya Kailkhura.

Contact

Anne M. Stark

Anne M. Stark

[email protected]

(925) 422-9799

Related Links

Journal of Chemical Information and ModelingTags

Advanced Materials and ManufacturingMaterials Science

Physical and Life Sciences

Featured Articles