Formation of high-purity uranium via laser-induced thermal decomposition

(Download Image)

(Download Image)

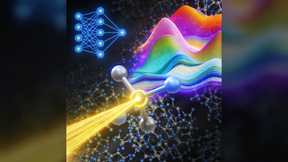

Laser heating of approximately 300 micrometer thick uranium nitride (UN) powder layer. The four images on the left are in situ optical images of a region of UN powder irradiated by the laser under high vacuum. The right image is the final UN decomposition product after heating under high vacuum.

Producing gram quantities of uranium metal in a controlled manner by traditional methods is challenging due to the complex chemistry of precursor material and extreme thermal requirements. In a recent study, LLNL researchers demonstrated a novel approach that combines modeling and an advanced experimental technique for extracting uranium from a uranium-containing compound. The team used a computational thermodynamic approach to identify a decomposition pathway to convert uranium nitride to uranium metal at temperatures exceeding 2500 kelvin under conditions of rapid material cooling. Employing laser-induced heating, which enables fine control of process location and rapid cooling, they exposed uranium nitride to extreme temperatures and cooling rates, achieving small-scale uranium metal production with yields up to 96%. The complete decomposition leading to pure uranium metal occurs at the high-temperature surface region, where laser-based heating induces a surface depression and molten pool of material. The researchers note that the capability they have developed advances the Lab’s core competency of actinide science and opens up new avenues to small-scale material synthesis.

This work was supported by the Laboratory Directed Research and Development Program (18-SI-001).

[B.C. Childs, A.A. Martin, A. Perron, E.E. Moore, Y. Idell, T.W. Heo, D.L. Rosas, C. Schaeffer-Cuellar, R.L. Stillwell, P. Söderlind, A. Landa, K.S. Holliday, and J.R. Jeffries, Formation of high purity uranium via laser induced thermal decomposition of uranium nitride, Materials and Design, available online on April 8, 2020, doi: 10.1016/j.matdes.2020.108706.]

Tags

Advanced Materials and ManufacturingMaterials Science

Physics

Physical and Life Sciences

Featured Articles