R&D 100 award finalists named for 2016

(Download Image)

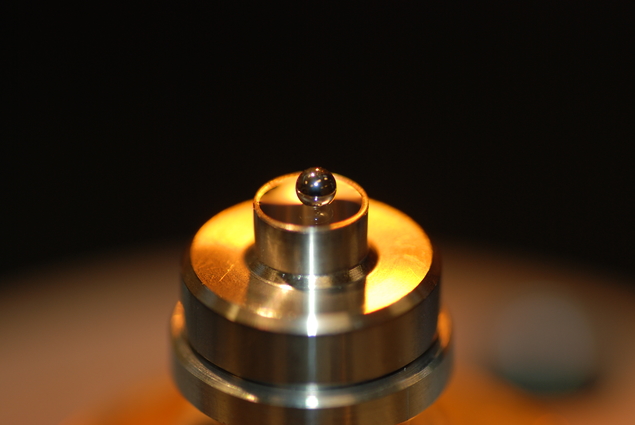

A stainless steel ball is supported by a thin sheet of plastic about 200 atoms thick. The plastic sheet was produced using a technology known as Polyelectrolyte Enabled Liftoff (PEEL), which was developed by LLNL researchers and General Atomics.

(Download Image)

A stainless steel ball is supported by a thin sheet of plastic about 200 atoms thick. The plastic sheet was produced using a technology known as Polyelectrolyte Enabled Liftoff (PEEL), which was developed by LLNL researchers and General Atomics.

Three technologies developed by LLNL researchers, and a fourth technology produced by a consortium of four national laboratories, including LLNL, and five universities have been tapped as finalists for the 2016 R&D 100 awards.

The awards, sponsored by the trade journal R&D Magazine, are given annually for the top 100 industrial inventions worldwide and are sometimes called the "Oscars of invention."

This year’s awards will be announced at a black-tie dinner on Nov. 3 at the Gaylord Convention Center in Washington, D.C.

Here are the Laboratory’s four finalists:

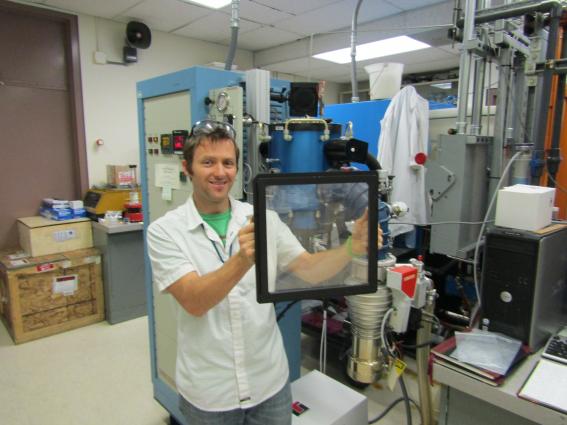

The GLO Transparent Ceramic Scintillator: This instrument dramatically increases high-energy, or mega-electron-volt, radiography throughput by providing seven times faster imaging than glass scintillators and decreases the X-ray dose required to obtain detailed imagery. Mega-electron-volt radiography is used to nondestructively image the 3D volume of complex objects. Developed for the Weapons and Complex Integration Directorate, the scintillator was produced in collaboration with industrial partners Nanocerox, Technology Assessment and Transfer, as well as American Isostatic Presses. The Lab researchers who helped develop the instrument are Nerine Cherepy, Zachary Seeley, Stephen Payne, Daniel Schneberk, Gary Stone, Scott Fisher and Peter Thelin.

The Polyelectrolyte Enabled Liftoff (PEEL): This technology is a robust, scalable method of fabricating freestanding polymer films that are larger, stronger and thinner than what conventional methods can produce. PEEL is used at the National Ignition Facility for the daily fabrication of membranes as thin as 30 nanometers that serve as compliant, load-bearing elements for laser targets. Because the process is easily scalable in size and manufacturing quantity, it could be applied to sensing, catalysis, filtration and wound-healing applications. The work, done in collaboration with General Atomics, was performed by Lab researchers Michael Stadermann, Salmaan Baxamusa, Philip Miller, Tayyab Suratwala, Chantel Aracne-Ruddle and Art Nelson.Solution-Grown Crystals for High-Energy Neutron Detection: This technology is a method for growing large-scale, economical stilbene crystals capable of efficiently distinguishing neutrons from gamma rays without the toxicity, flammability and handling difficulties that commercial liquid scintillators present. The technology has been licensed to Inrad Optics for commercial crystal production. Detecting and distinguishing between neutrons and gamma rays is critical to identifying nuclear substances such as uranium and differentiating them from benign radioactive sources. The technology was developed by Lab employees Natalia Zaitseva, Leslie Carman, Andrew Glenn and Stephen Payne.

Carbon Capture Simulation Initiative (CCSI): Now in its fourth generation, this toolkit consists of a suite of computational tools and models to accelerate the development of carbon capture technology for manufacturers and businesses. Launched in 2011, the CCSI’s objectives are to develop, demonstrate and deploy advanced computational tools and validated multi-scale, multi-physics models. Its mission is to reduce the risk and time required to develop and scale up new carbon capture and related chemical process technologies. It has been developed by five national labs – LLNL, National Energy Technology, Lawrence Berkeley, Los Alamos and Pacific Northwest national laboratories – and five universities – Carnegie Mellon University, West Virginia University, Princeton University, Boston University and the University of Texas at Austin. Lab scientist Charles Tong has worked on the collaboration.To date, LLNL has captured a total of 155 R&D 100 awards since 1978.

Contact

Stephen Wampler

Stephen Wampler

[email protected]

(925) 423-3107

Related Links

R&D MagazineTags

Industry CollaborationsTechnology Transfer

Featured Articles