LAB REPORT

Science and Technology Making Headlines

Nov. 21, 2014

Sierra is the next in a long line of supercomputers at Lawrence Livermore National Laboratory.

New heights for supercomputing

Big Blue can still move big iron.

IBM and Lawrence Livermore last week announced a $325 million deal to supply the Department of Energy with a new kind of supercomputer that will move data far faster and more efficiently than competing hardware systems. The supercomputers, nicknamed Sierra and Summit, will go online in 2017 and 2018 at Lawrence Livermore and Oak Ridge national laboratories, already home to some of the world’s fastest supercomputers.

The DOE also announced a separate $100 million program to continue developing even faster machines.

This simulation shows the possible behavior of a gas cloud (G2) that has been observed approaching the black hole at the center of the Milky Way. Graphic by ESO/MPE/Marc Schartmann.

Black hole passes on gassy cloud

In a showdown of black hole versus G2 — a cloud of gas and dust — it looks like G2 won.

Recent research shows that G2 came within 30 billion kilometers of the super-massive black hole at the center of our galaxy, yet managed to escape from the gravitational pull of the black hole.

Initially, a supercomputer simulation prepared by two Lawrence Livermore physicists and a former postdoctoral researcher more than two years ago suggested that some of G2 would survive, although its surviving mass would be torn apart, leaving it with a different shape and questionable fate. The team’s simulations allowed the members to more efficiently follow the cloud's progression toward the black hole.

But recent observations by an outside group show that G2 managed to escape the appetite of the black hole.

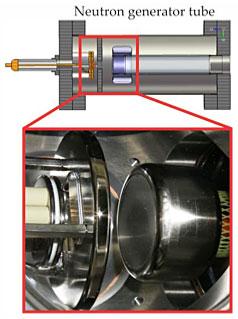

A prototype suitcase-sized neutron source can detect uranium that may be shielded by lead.

Detection in a suitcase

Uranium — especially the highly enriched weapons-grade version — can be difficult to spot because it is easily shielded by a relatively small amount of lead, which absorbs the fissile material's emissions.

However, neutrons directed at a suspect object can readily penetrate the lead shielding and produce enough fission neutrons and gamma rays to be detected. For field operations, small and light neutron sources are needed.

Jennifer Ellsworth and a team of researchers at Lawrence Livermore have developed a suitcase-sized prototype neutron source that they say can be shrunk to a lunchbox-sized device that could be easily transported to inspect a suspicious item.

Intrinsic Use Control uses a weapon’s fluctuating radiation fields to create use control numbers, known only to the weapon, which protects the weapon and its components from unauthorized use.

Can’t touch this

Mark Hart, a scientist and engineer at Lawrence Livermore, has been awarded the 2015 Surety Transformation Initiative (STI) Award from the National Nuclear Security Administration’s Enhanced Surety Program.

The STI award aims to stimulate and encourage the development of potentially transformational nuclear weapon surety technologies and explore innovative, preferably monumental shift solutions, to unmet surety needs.

Hart’s winning proposal is for Intrinsic Use Control, a concept that is capable of providing improved quantifiable safety and use control within a nuclear weapon. This is accomplished by designing the components to function in a way that cannot be replicated by any individual. Using the IUC concept, weapon components would be initialized and made secure during assembly by using the weapon’s fluctuating radiation field to generate unique component IDs and use-control numbers, only known to the weapon. Any anomaly in their verification, caused by removal or replacement of any protected component, will cause all protected components to be unusable.

Amanda Wu images an additively manufactured part using digital image correlation.

Science of stress

Lawrence Livermore researchers have developed an efficient method to measure residual stress in metal parts produced by powder-bed fusion additive manufacturing.

This 3D printing process produces metal parts layer by layer using a high-energy laser beam to fuse metal powder particles. When each layer is complete, the build platform moves downward by the thickness of one layer, and a new powder layer is spread on the previous layer.

While this process is able to produce quality parts and components, residual stress is a major problem during the fabrication process. That’s because large temperature changes near the last melt spot -- rapid heating and cooling -- and the repetition of this process result in localized expansion and contraction, factors that cause residual stress.

The new process is able to provide fast and accurate measurements of surface-level residual stresses in additive manufacturing parts.