LAB REPORT

Science and Technology Making Headlines

April 19, 2024

Inside the LSST Camera clean room, SLAC staff scientist test a raft of CCDs within a scaled-down version of the camera’s cryostat. Image courtesy of Andy Freeberg/SLAC National Accelerator Laboratory.

Freeze frame on the universe

Scientists and engineers at SLAC National Accelerator Laboratory and their collaborators including Lawrence Livermore have completed construction of the Legacy Survey of Space and Time (LSST) camera.

The 3,200-megapixel camera will now be installed on a telescope in Chile to help researchers observe our universe in unprecedented detail. Over the next decade, this camera will generate an enormous amount of data that researchers will use to gain new insights into the universe, including dark energy, dark matter and the Milky Way galaxy. The data also will help us better understand the changing night sky and our own solar system.

The Legacy Survey of Space and Time (LSST) camera module has been in the works for more than two decades. Finally, in 2015, the U.S. Department of Energy approved its construction. Since then, technicians at SLAC National Accelerator Laboratory have been hard at work piecing together the module’s massive sensor array, which is made up of 189 individual 16-megapixel sensors.

The custom-designed CCD sensors in the 3.2-gigapixel array now number 201, and each pixel measures about 10 microns wide. The focal plane has been sealed in a vacuum chamber by a 3-ft-wide lens, while the front lens is more than 5 ft (1.5 m) in diameter. All three lenses in the camera setup were manufactured by Lawrence Livermore National Laboratory.

A photo taken by a scanning electron microscope shows a pit at the surface of an additively manufactured (3D-printed) stainless steel part. Image by Thomas Voisin/LLNL.

It’s the pits

Why is 3D printed 316L stainless steel prone to pitting corrosion in seawater? That is the question researchers from Lawrence Livermore National Laboratory have been diligently trying to answer. Their thorough study of this metal, utilized in naval applications, aims to uncover the underlying causes of its degradation. Their findings suggest that slag, left behind during laser melting, accumulates on the surface of the material, resulting in the formation of cavities or pits.

Used in many industrial applications, metals are often subject to corrosion, i.e., degradation by chemical reactions caused by the environment. Corrosion can be controlled, but it’s important to know what causes it. There are several forms of corrosion, including pitting. In concrete terms, the metal undergoes degradation of its protective oxide layer, and loses electrons in the process.

When present in an aquatic environment, an electrochemical reaction occurs, resulting in the creation of small holes, hence the name “pitting corrosion.” The severity of the repercussions for the part in question varies depending on the depth of these cavities. Interestingly, controlling pitting corrosion in seawater poses significant challenges. This is precisely why naval applications opt for 316L stainless steel, known for its exceptional mechanical properties and resistance to such pitting corrosion.

However, can 3D-printed 316L stainless steel effectively mitigate pitting corrosion? With the marine industry showing a growing interest in additive manufacturing, both in polymer and metal, this question gains significance, particularly concerning metal certification. This is the very reason why researchers at Lawrence Livermore embarked on this study.

Lead author Shohini Sen-Britain said: “Pitting corrosion is extremely difficult to understand due to its stochastic nature, but we determined the material characteristics that cause or initiate this type of corrosion. While our slags looked different than what had been observed in conventionally manufactured materials, we hypothesized that they could be a cause of pitting corrosion in 316L.”

LLNL researchers and collaborators have looked at the effect of heat on tungsten. Image by Adobe Stock.

Turning on the heat

Researchers at SLAC National Accelerator Laboratory and Lawrence Livermore have reportedly begun looking into tungsten’s ability to conduct heat for nuclear fusion reactors and other clean energy technology.

According to the team, recent advancements in this research have presented opportunities to help speed up the development of more efficient and resilient fusion reactor materials, as well as aerospace equipment like rocket engine nozzles and turbine blade coatings.

To combat this issue, researchers have been looking into heat management, focusing on the special metal called tungsten. The new research reportedly highlights the metal’s potential to improve fusion reactor technology based on this ability to conduct heat.

The study's results revealed that in tungsten, the interaction between phonons is much weaker than expected, meaning that tungsten can conduct heat more efficiently than previously thought.

“Our findings are particularly relevant for designing new, more robust materials for fusion reactors,” said collaborator Alfredo Correa, a scientist at Lawrence Livermore National Laboratory.

The high performance computing (HPC) publication HPCwire has selected Lawrence Livermore National Laboratory computer scientist Todd Gamblin as one of its “People to Watch” in HPC for 2024. Graphic courtesy of HPCwire.

A person to watch

Todd Gamblin, a distinguished member of technical staff in the Livermore Computing Division at LLNL has been selected as a 2024 HPCwire Person to Watch. The program recognized 12 HPC professionals who “play leading roles in driving innovation within their particular fields, making significant contributions to society as a whole.”

Gamblin is the creator of the Spack HPC package management tool. He discussed the genesis of this effort and what problem he was trying to solve.

Gamblin said: “Spack was created out of frustration with the state of building software on HPC systems. HPC has always been a bleeding-edge field, and the open-source software we’ve come to know and love isn’t always well-supported. Most of the time, you want to build your software yourself with a fast compiler, maybe some optimized system libraries, with some “special” vendor programming environment. The odds that the developer of the software tested with your particular system configuration are really low when there’s only one system like yours.”

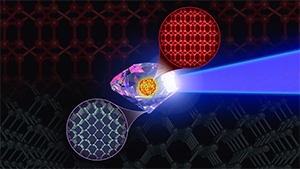

Supercomputer simulations predicting the synthesis pathways for the elusive BC8 “super-diamond,” involving shock compressions of diamond precursor, inspire ongoing Discovery Science experiments at NIF. Image by Mark Meamber/LLNL.

When the diamond gets tough

Simulations of an elusive carbon molecule that leaves diamonds in the dust for hardness may pave the way to creating it in a lab.

Known as the eight-atom body-centered cubic (BC8) phase, or super-diamond,, the configuration is expected to be up to 30% more resistant to compression than diamond – the hardest known stable material on Earth.

Lawrence Livermore physicists and collaborators ran quantum-accurate molecular-dynamics simulations on a supercomputer to see how diamond behaved under high pressure when temperatures rose to levels that ought to make it unstable, revealing new clues on the conditions that could push the carbon atoms in diamond into the unusual structure.

The BC8 phase has previously been observed here on Earth in two materials, silicon and germanium. Extrapolating the properties of BC8 seen in those materials has allowed scientists to determine how the phase would manifest in carbon.