LAB REPORT

Science and Technology Making Headlines

Nov. 3, 2023

This is the Nevada National Security Site’s U1a Complex. The test took place in Area 12's P tunnel at the Nevada National Security Site. Photo courtesy of U.S. Department of Energy.

Going underground is a blast

On Oct. 18, beneath the Nevada desert, the National Nuclear Security Administration (NNSA) intentionally set off a non-nuclear explosion. It has been over three decades since the United States has detonated a nuclear weapon in testing, but the ability to detect such tests, especially underground, informs and guides U.S. responses to other tests.

The Oct. 18 explosion, while not nuclear in nature, took place in the bones of old nuclear testing infrastructure, because it was designed to improve detection of nuclear tests.

In the absence of live tests, simulated tests with computer models have informed the continued study and maintenance of the U.S. nuclear arsenal, powered by supercomputing and the extensive data collected during the nearly five decades of active nuclear testing.

The recent test builds on previous work done at the Nevada site. From 2010 to 2019, researchers in the U.S. nuclear enterprise, including scientists from the NNSA as well as researchers from Lawrence Livermore National Laboratory, conducted the Source Physics Experiments. These were designed to help the United States be able to distinguish earthquakes from underground explosions, improving knowledge of both weapons testing and seismic activity.

Green hydrogen is an ecological and sustainable alternative to fossil fuels. Image by Adobe Stock.

Hydrogen goes green

A team at the Yale School of Engineering and Applied Sciences and Lawrence Livermore is designing a device to produce green hydrogen — hydrogen that is not sourced from fossil fuels or nuclear power and is manufactured in a scalable way.

The device proposal submitted to the Department of Energy (DOE), is one of 22 projects receiving a total of $42 million in funding from the agency. All the projects contribute to the DOE’s goal of reducing the cost of green hydrogen to one dollar per one kilogram in one decade.

Scaling the size of existing hydrogen producing devices would reduce the devices’ efficiency. Existing devices also are impractical to manufacture at scale, so efficiently producing large amounts of green hydrogen required a ground-up redesign.

Designing the device required new innovations to both increase the scale of hydrogen production and to make the device manufacturable en masse. The team had to design new materials to capture light and a new design for the external coating pfr the device.

In Diode-based Additive Manufacturing, the laser light is sourced by a set of four diode laser arrays and a pulsed laser. It passes through the Optically Addressable Light Valve, which patterns an image of a two-dimensional “slice” of the desired 3D part. The laser then flash prints an entire layer of metal powder at a time, instead of scanning with a laser as with traditional selective laser melting systems. Photo by LLNL.

Scaling up with 3D printing

The auto industry’s thirst for 3D-printed car parts is heating up, and the latest development is a doozy. The U.S. startup Seurat Technologies has just closed a Series C funding round for its new 3D-printed metal technology with new investor Honda on board. Returning for the Series C round are other automakers and suppliers including Porsche, Denso and the Ventures arm of General Motors.

The new system arose from the challenge of fabricating the reaction chamber for a laser-driven fusion system at Lawrene Livermore’s National Ignition Facility (NIF). The reactor material had to be a metal that could withstand wide variations of temperature — including a peak of nearly 1,100 degrees Fahrenheit — without cracking. The Seurat team concluded that deploying additive manufacturing on a steel nanoparticle composite was the way to go. However, existing 3D printing methods sacrifice speed for precision and vice versa.

The team found the key to a solution at NIF. The Livermore lab had previously developed a pixelated laser system called OALV, or Optically Addressed Light Valve. The system separates one laser beam into many individual parts, rather than trying to combine different laser sources in one operation.

OALV was initially developed to support the lab’s LEOPARD (Laser Energy Optimization by Precision Adjustments to the Radiant Distribution) system. By 2017 the Lab was promoting it as a new, improved tool for fabricating 3D-printed metal products, enabling additive manufacturing to produce larger parts at faster speeds with greater precision than possible with existing devices.

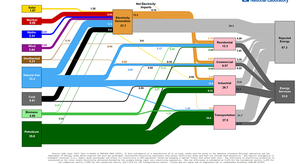

Americans used more renewables to generate electricity than in previous years, according to the most recent energy and carbon flow charts produced by Lawrence Livermore National Laboratory.

Going with the flow

To better understand how the world can decarbonize energy systems, it’s critical to understand the significant and complex role oil products play in today’s modern life.

Hydrocarbons are the fundamental compounds of crude oil, and the petroleum products refined from that oil make up the largest share of the world’s energy consumption.

Lawrence Livermore National Laboratory puts out an annual report outlining energy consumption in the US. Summarized in an influential Sankey diagram, the report depicts the country’s energy flows. In 2022, the United States consumed about 100 quadrillion British thermal units (BTUs) of energy. A quadrillion BTUs is also known as a quad. (For reference, a gallon of gasoline has about 120,000 BTUs and a toaster uses about 100 BTUs in the two minutes it takes to burn your toast).

Of its 100 quads, more than one third of total American energy consumption is petroleum.

An LLNL team has helped develop a new toolkit to ensure that carbon capture storage (CCS) is safe. Image by Adobe Stock.

A tool to store carbon safely

A new toolkit will help operators of underground carbon dioxide (CO2) storage sites assess the likelihood and magnitude of seismic activity that could arise from commercial-scale injection.

While geologic storage of CO2 has been shown to be safe and effective, concerns remain about the potential to induce new seismic activity as a result of large-scale injection operations. While the vast majority of measured seismic activity from commercial-scale carbon storage operations is too small in magnitude to be felt at the surface and results in no impact, it is important to address stakeholder concerns about the potential to induce larger-magnitude seismic activity.

Effectively forecasting potential CO2-injection induced seismicity requires a robust understanding of the underlying physical processes, an ability to develop and apply physics-informed and data-driven modeling approaches, and the vision to bring these together in a framework that is useful to a wide range of stakeholders. That’s where the new toolkit, called the Operational FoRecastIng Of INduced Seismicity toolkit (ORION) comes in.

ORION, developed by Lawrence Livermore researchers, is an open-source, observation-based toolkit designed to forecast how potential induced seismic hazard (i.e., probabilistic assessment of the magnitude and frequency of induced seismic events) may evolve in response to CO2 injection.