DOE HPC4Mfg Program funds 13 new projects to jumpstart clean energy technologies

(Download Image)

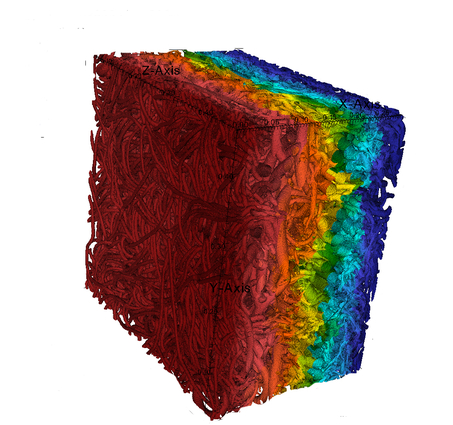

A simulation of pressure applied to felt used to absorb water in a paper drying process is one of the projects that received DOE funding. Photo courtesy of David Trebotich/Lawrence Berkeley National Laboratory.

(Download Image)

A simulation of pressure applied to felt used to absorb water in a paper drying process is one of the projects that received DOE funding. Photo courtesy of David Trebotich/Lawrence Berkeley National Laboratory.

A U.S. Department of Energy (DOE) program designed to spur the use of high performance supercomputers to advance U.S. manufacturing has funded 13 new industry projects for a total of $3.8 million.

The High Performance Computing for Manufacturing (HPC4Mfg) Program creates an ecosystem that allows experts at DOE’s national laboratories to work directly with manufacturing industry members to teach them how to adopt or advance their use of high performance computing (HPC) to address manufacturing challenges with a goal of increasing energy efficiency, reducing environmental impacts and advancing clean energy technologies.

The partnerships use world-class supercomputers and scientific expertise from Lawrence Livermore National Laboratory (LLNL), which leads the program, and partner laboratories Lawrence Berkeley and Oak Ridge national laboratories (LBNL and ORNL), which in turn team up with U.S. manufacturers.

"We’re excited about this second round of projects because companies are bringing forward challenges that we can help address, which result in advancing innovation in U.S. manufacturing and increasing our economic competitiveness," said LLNL mathematician Peg Folta, the director of the HPC4Mfg Program.

The 13 new projects include: LLNL partnering with GE Global Research to study how to mitigate defects when 3D printing metal parts; the Alzeta Corporation partnering with LBNL to reduce emissions from semiconductor processing that could potentially harm the ozone layer; and Actasys, Inc. partnering with ORNL to decrease the fuel consumption of tractor trailer trucks by actively modifying their aerodynamics to reduce drag.

The program has previously funded 16 projects ranging from improving turbine blades for aircraft engines to reducing heat loss in electronics to improving fiberglass production. Partners range from small to large companies, industry consortiums and institutes.

The Advanced Manufacturing Office within DOE's Office of Energy Efficiency and Renewable Energy funded LLNL to establish the HPC4Mfg Program in March 2015. The Advanced Scientific Computing Research Program within DOE’s Office of Science supports the program with HPC cycles through its Leadership Computing Challenge allocation program.

By using HPC in the design of products and industrial processes, U.S. manufacturers can reap a number of benefits, such as accelerating innovation, lowering energy costs, shortening testing cycles, reducing waste and rejected parts and cutting the time to market.

Scientists at the national labs benefit by expanding computer codes and applying them to different problem areas. The skills and new applications they develop through these public-private partnerships can then be applied to DOE missions in such areas as energy, materials science and national security.

Although the program is focused on using national lab HPC resources to bolster manufacturing, it is possible that other fields, such as transportation, the modern electrical grid and advanced integrated circuitry also could benefit. As the program broadens, other national laboratory partners are expected to join.

For a full list of the projects, go to the web.

Contact

Don Johnston[email protected]

925-423-4902

Related Links

Office of Energy Efficiency and Renewable Energy news releaseThe High Performance Computing for Manufacturing

DOE Advanced Manufacturing Office

Office of Energy Efficiency and Renewable Energy

Tags

HPC, Simulation, and Data ScienceComputing

Featured Articles