LLNL and Precision Neuroscience collaboration aims to develop next-generation neural implants

(Download Image)

(Download Image)

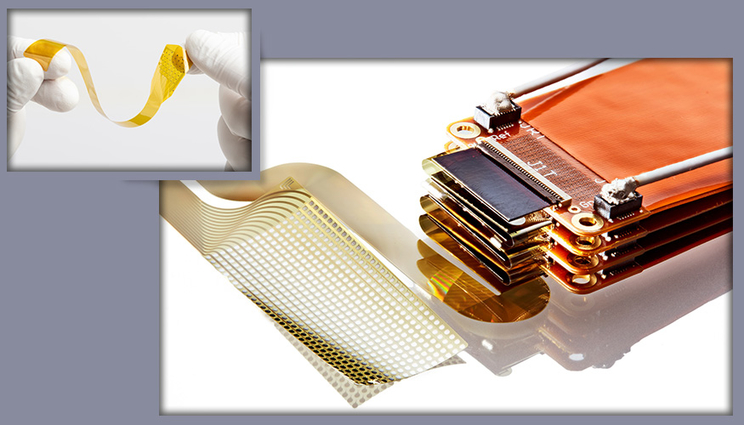

Under a three-year collaboration, LLNL scientists and engineers will work with Precision Neuroscience to develop future versions of the company’s flexible, thin-film neural implant for patients with a variety of neurological disorders. LLNL’s 512-channel thin-film array is capable of electrically recording neural activity from the surface of the brain. (Photo: Randy Wong/LLNL). Inset: Precision’s Layer 7 Cortical Interface, a high-channel-count cortical surface array, packs 1,024 electrodes into a surface area of 1.5 square centimeters and is thinner than a human hair. (Photo courtesy Precision Neuroscience)

Lawrence Livermore National Laboratory (LLNL) has joined forces with Precision Neuroscience Corporation (Precision) to advance the technology of neural implants for patients suffering from a variety of neurological disorders, including stroke, spinal cord injury and neurodegenerative diseases such as Lou Gehrig's disease.

Under the three-year collaboration, outlined in a Cooperative Research and Development Agreement (CRADA), LLNL scientists and engineers will work with Precision to develop future versions of the company’s neural implant – a thin-film microelectrode array called the Layer 7 Cortical Interface – with enhanced longevity. The implant is designed to allow users to operate computer systems through thought, which could benefit patients who have lost motor coordination or the ability to speak. Precision intends to transfer the techniques developed under the CRADA to its Addison, Texas-based manufacturing subsidiary, Precision BioMEMS, for production.

The collaboration aims to result in a mass-produced neural implant based on technology developed in partnership with LLNL. The project will leverage LLNL's extensive background in developing flexible, thin-film multielectrode neural implants, as well as its Biomedical Foundry infrastructure, which provides a dedicated micro-fabrication facility with a regulatory-compliant quality management system (QMS) for prototype medical device manufacturing. LLNL also brings its long history of collaborating with outside experts conducting intraoperative studies with implantable devices, which has led to performance improvements and informed the design of longer-term implants.

“We are very excited to embark on this collaboration with Precision, which we anticipate will significantly move the needle in the development of neural implants for the betterment of patients,” said Razi Haque, Implantable Microsystems Group lead at LLNL. “Combining Livermore’s demonstrated expertise and technical know-how with Precision's innovative approach and skilled team will further both organizations’ efforts to push the boundaries of medical innovation and make meaningful contributions to the field of neuroscience.”

Founded in 2021, Precision aims to provide breakthrough treatments for the hundreds of millions of patients worldwide suffering from neurological illnesses. The company’s implants combine high-bandwidth brain-computer interface technology with a minimally invasive surgical approach ― one that is designed to cause no damage to healthy brain tissue. Precision began testing its product in human clinical trials last spring in collaboration with West Virginia University’s Rockefeller Neuroscience Institute. Precision is seeking to gain Food and Drug Administration clearance for its first commercial device in 2024.

“LLNL is one of the premier research laboratories in the world. Their team holds deep knowledge and expertise in thin-film microfabrication techniques, and we share common goals in translating advanced manufacturing technology to help millions of patients with neurological disease,” said Craig Mermel, president and chief product officer of Precision. “This exciting collaboration allows our teams to iterate on advanced fabrication techniques faster and with quality standards appropriate for human clinical use, while ensuring that the eventual commercial translation of these strategic manufacturing capabilities stays within the United States.”

Other goals for the collaboration include LLNL supporting Precision in obtaining regulatory approval for longer-term implants, enhancing LLNL's QMS and helping Precision to translate materials and process advancements into manufacturing techniques to further the company’s long-term goal of building a broadly impactful brain-computer interface.

LLNL’s Innovation & Partnerships Office facilitated the CRADA.

For more information, visit LLNL's Bioscience and Bioengineering web page and Precision.

Contact

Jeremy Thomas

Jeremy Thomas

[email protected]

(925) 422-5539

Related Links

Meet the next generaion of neural implantsLLNL’s Micro- and Nanotechnology Center

LLNL-developed thin-film electrodes reveal key insight into human brain activity

LLNL/UCSF-developed implants enable unprecedented recordings of brain activity

LLNL Innovation and Partnerships Office

LLNL Center for Bioengineering

Tags

Bioscience and BioengineeringEngineering

Industry Collaborations

Featured Articles