LLNL’s new diffraction gratings will enable the world’s most powerful laser

(Download Image)

(Download Image)

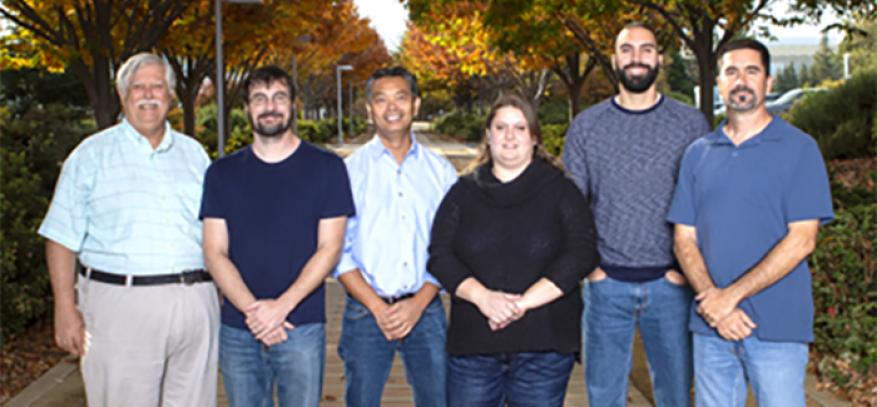

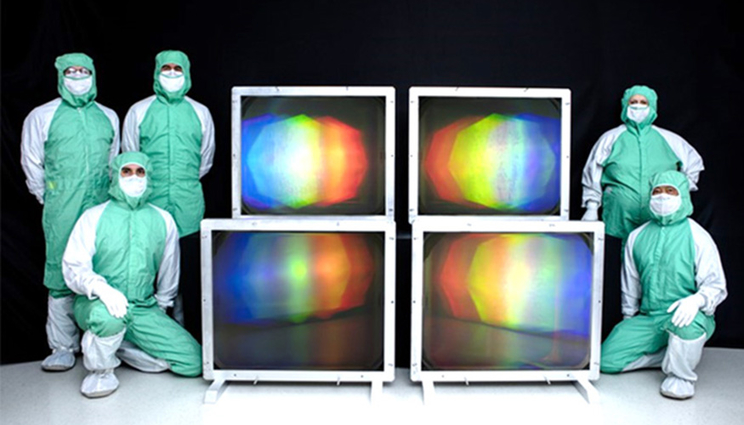

Members of LLNL’s Diffractive Optics Group with four of the 85x70-centimeter HELD gratings to be installed in the ELI-Beamlines L4-ATON laser system. Meter-scale HELD gratings have the potential to facilitate future 20-to-50-petawatt-class ultrafast laser systems.

Lawrence Livermore National Laboratory (LLNL) researchers and their collaborators have developed new high-energy pulse compression gratings that will be used in the world’s highest-power laser system, designed to deliver up to 10 petawatts (quadrillion watts) of peak power. A petawatt is about 1,000 times the capacity of the entire U.S. electric grid.

The high-energy, low-dispersion (HELD) multi-layer dielectric gratings will be installed in the L4-ATON laser system at the ELI-Beamlines Facility in the Czech Republic. L4-ATON can generate 1.5 kilojoules (kJ) of energy in 150-femtosecond (quadrillionths of a second) pulses, equal to an unprecedented 10 petawatts of power, at a repetition rate of one shot per minute.

Multi-petawatt laser technology opens the door to groundbreaking research in areas such as plasma and high-energy-density physics, astrophysics, laser-driven particle acceleration, enhanced medical diagnostics, industrial processing techniques and nuclear materials detection.

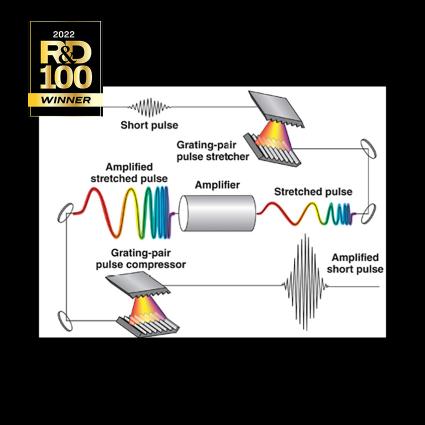

In chirped-pulse amplification, an ultrashort laser pulse is amplified to the petawatt level, with the laser pulse being stretched out temporally and spectrally, then amplified and then compressed again. The stretching and compression devices (the gratings) that ensure different color components of the pulse travel different distances are susceptible to damage from redirecting beam pulses carrying petawatt loads.

LLNL’s HELD gratings, which received a 2022 R&D 100 Award as one of the top 100 industrial inventions worldwide, can deliver 3.4 times more total energy than current state-of-the-art technology. They were developed in a collaboration involving LLNL’s Diffractive Optics Group, ELI-Beamlines, Spectra Physics–Newport of Milpitas, Calif. and National Energetics of Austin, Texas.

Petawatt and multi-petawatt lasers rely on a Nobel Prize-winning technology called chirped-pulse amplification to stretch, amplify and then compress a high-energy laser pulse to avoid damaging optical components. Pulse-compression gratings must be sufficiently large, efficient and robust to withstand the high fluence (energy density) of the laser pulses generated by petawatt-class lasers like the National Ignition Facility’s (NIF) Advanced Radiographic Capability (ARC).

“The HELD gratings are advancements over the NIF ARC-like gratings, allowing for significantly higher energy outputs and access to new regimes of science,“ said LLNL Senior Laser Scientist Hoang Nguyen, leader of the NIF & Photon Science Diffractive Optics Group.

“The 85-by-70-centimeter HELD gratings, configured at a Littrow angle (the angle of maximum grating efficiency) of 37 degrees, allow for a larger beam width — 62.5 centimeters,” he said. “Increasing the beam height to produce a square beam and accounting for the difference in LIDT (laser-induced damage threshold) results in approximately 3.4 times more total energy on the grating compared to the ARC high-dispersion, 76.5-degree angle of incidence grating design.

“The HELD grating’s excellent uniformity is due to a design with high efficiency over a large range of groove widths and heights and well-controlled dielectric layer thickness,” Nguyen added. Operating at the grating’s Littrow angle results in maximum diffraction efficiency and bandwidth but requires tilting the angle of the gratings so the beam reflects slightly upward, or out-of-plane.

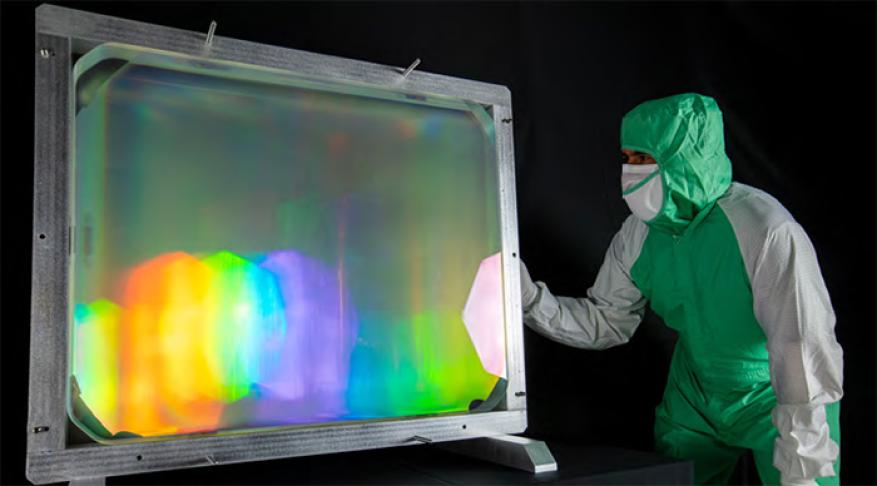

A technician inspects one of eight recently fabricated HELD gratings to be installed in the L4-ATON laser system’s 18-meter-long, 55-ton compressor.

Multilayer dielectric (MLD) gratings are composed of a base substrate upon which layers of dielectric mirrors with varying refractive indices are stacked, topped by a layer of ion-etched photoresist, a light-sensitive material that is fine-tuned to the desired diffraction specifications. MLD gratings can substantially enhance the diffraction efficiency of grating compressors over a large bandwidth, or range of frequencies. Unlike the metal used in traditional gratings, dielectric materials are non-conducting and can absorb 500 times less energy than previous designs.

Members of the NIF & Photon Science Diffractive Optics Group, from left: Mike Rushford, James Nissen, Hoang Nguyen, Candis Jackson, Sean Tardif and Brad Hickman. The Diffractive Optics Group develops, creates and provides a variety of custom critical optical components for researchers worldwide. In addition to developing and operating some of the world’s highest-energy laser systems, LLNL is the recognized leader in fabricating diffractive optics.

The L4-ATON laser, named after an Egyptian sun god, is a companion to the L3-HAPLS laser system designed, developed and constructed by the NIF & Photon Science Directorate and delivered to ELI-Beamlines in 2017. The L3-HAPLS (High-Repetition-Rate Advanced Petawatt Laser System) also benefitted from advances in LLNL gratings technology (see “New Gratings Promise 20 Percent Performance Boost for Ultrafast Lasers”).

L4-ATON was developed by a consortium led by National Energetics in partnership with laser manufacturer Ekspla of Vilnius, Lithuania, and ELI-Beamlines. The system uses technologies developed in collaboration with the University of Texas and LLNL for the Texas Petawatt Laser in Austin, such as optical parametric chirped-pulse amplification followed by high-energy amplification in neodymium glass-disc amplifiers using two types of laser glass.

The HELD gratings are among three LLNL technologies receiving 2022 R&D 100 Awards. The others are:

- Tailored Glass Using Direct Ink Writing Technology (DIW): DIW is an additive manufacturing process to print silica-based optics and glass components with customizable forms and spatially varying material properties. As part of the process, the flow of multiple glass-forming inks is finely controlled to achieve the desired structure and optical properties. Subsequent heat treatment renders a dense, transparent glass product.

- Multifunctional, 3D-Printable Inks for Energy Products (Energy Inks): Energy Inks is a three-dimensional (3D) printer feedstock that allows the production of a functioning battery and other devices. 3D printing with polymers allows a newer and more efficient method of prototyping. Now Energy Inks, which have functional properties, are optimized to enable next-generation, high-performance 3D-printed devices for energy storage, catalysis, filtration, sensors and other uses.

In addition, Area Printing™, a technology developed by researchers from LLNL in collaboration with Seurat Technologies of Wilmington, Mass., was named a finalist in the 2022 R&D 100 competition. Area Printing uses large-area pulsed laser powder bed fusion to flash-print one area of metal powder at a time, dramatically reducing production time and costs and opening up the possibility of revolutionizing industrial metal production in the United States.

With this year’s results, the NIF & Photon Science Directorate and its predecessor, the Laser Programs Directorate, have captured 66 R&D 100 awards out of a total of 176 won by the Laboratory since 1978. The awards will be presented at the R&D 100 Awards banquet in San Diego on Nov. 17.

– Charlie Osolin

Contact

Michael Padilla

Michael Padilla

[email protected]

(925) 341-8692

Related Links

“Livermore Researchers Collect Three Awards Among the Top 100 Industrial Inventions"“Researchers Design a Compact High-Power Laser Using Plasma Optics”

“Lasers Without Limits"

“Super-Fast, Super-Powerful Lasers Are About to Revolutionize Physics"

“New Gratings Promise 20 Percent Performance Boost for Ultrafast Lasers"

“High-Average-Power Ultrafast Lasers”

Tags

Lasers and Optical S&TLasers

National Ignition Facility and Photon Science

Physical and Life Sciences

Science

Featured Articles