Newly funded HPC4Mfg project targets more energy-efficient steelmaking

(Download Image)

(Download Image)

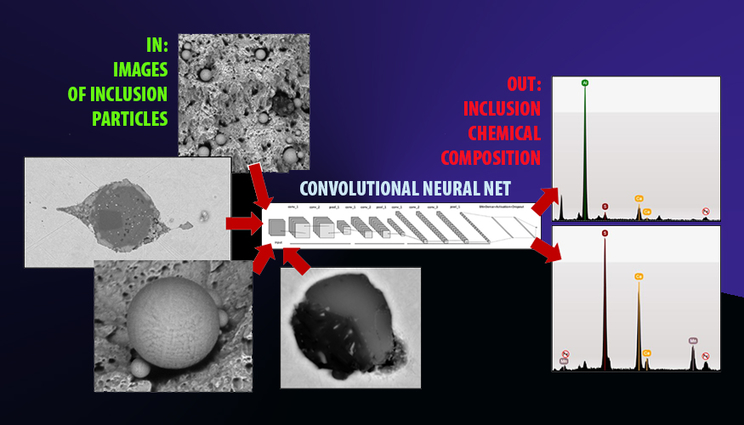

Under a newly funded High Performance Computing for Manufacturing project, Lawrence Livermore National Laboratory will partner with steel and mining company ArcelorMittal to couple computer vision and machine learning methods with HPC resources to reduce emissions and defects from inclusions (oxide, sulfide or nitride particles) in steel manufacturing. Shown is an example of backscattered electron scanning electron microscope images showing different types of inclusions. The objective of the project is to relate these images to measured chemical composition. Image courtesy of ArcelorMittal.

A Lawrence Livermore National Laboratory (LLNL)-led collaboration targeted at using machine learning to reduce defects and carbon emissions in steelmaking is one of eight new projects receiving Department of Energy (DOE) funding through the High Performance Computing for Manufacturing (HPC4Mfg) Program. DOE’s Office of Energy Efficiency and Renewable Energy (EERE) announced the awards today.

As part of the project, LLNL will partner with steel and mining company ArcelorMittal to couple computer vision and machine learning methods with HPC resources to reduce defects from inclusions (oxide, sulfide or nitride particles) in steel manufacturing. The technology will be used to accelerate analysis of steelmaking – usually performed through automated scanning electron microscopy on samples taken from liquid steel — to enable near-real-time process control and save energy by avoiding rejection of products due to poor quality.

The iron and steel industry consumes an estimated 6 percent of the energy used by the U.S. manufacturing sector. The technology addressed in the project could reduce this number by 1 percent to 2 percent and lessen CO2 emissions by about 1.5 million tons per year, according to the company. The LLNL principal investigator is Michael Zelinski.

HPC4Mfg is managed by LLNL for the DOE EERE’s Advanced Manufacturing Office (AMO). Total funding by AMO for the Spring 2021 round of projects is $2.3 million.

Other new HPC4Mfg projects include collaborations between Oak Ridge National Laboratory (ORNL) and Collaborative Composite Solutions Corporation; Lawrence Berkeley National Laboratory (LBNL) and Diamond Foundry; Pacific Northwest National Laboratory and Fairmount Technologies, LLC; LBNL and Ferric Inc.; Argonne National Laboratory (ANL) and Noble Thermodynamic Systems Inc.; ORNL and Spar Energy LLC; and ANL and TotalEnergies E&P Research & Technology USA, LLC. Selected industry partners are required to provide at least 20 percent of in-kind funding for the projects.

For full project details, visit the web.

The HPC4Mfg Fall 2021 solicitation is ongoing. Potential industry and academic partners can submit proposals here. The deadline for concept papers is Jan. 7, 2022, at 5 p.m. PST.

Contact

Jeremy Thomas

Jeremy Thomas

[email protected]

(925) 422-5539

Related Links

ArcelorMittalHPC4energy

Solicitations

Tags

ASCHPC, Simulation, and Data Science

Computing

Engineering

Energy

Featured Articles