A method for purer and safer explosives

(Download Image)

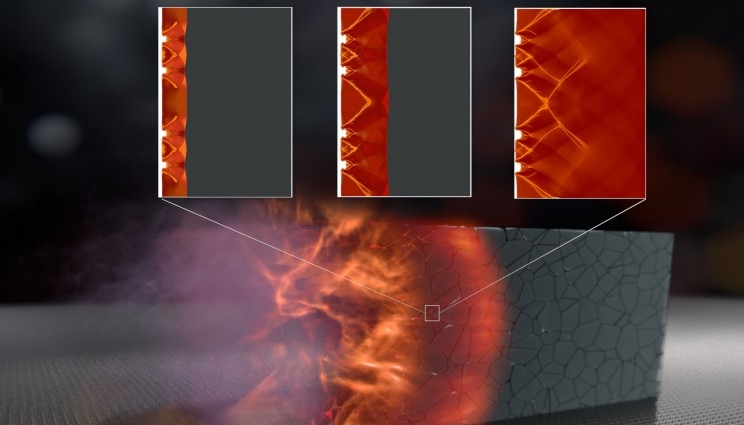

Image by Yong Han/Chemical Sciences and Dan Moore/TID Scanning electron microscope images of 1, 3, 5-triamino-2,4,6-trinitrobenzene (TATB) crystals before and after the recrystallization in the ionic liquid-DMSO co-solvent system. .

(Download Image)

Image by Yong Han/Chemical Sciences and Dan Moore/TID Scanning electron microscope images of 1, 3, 5-triamino-2,4,6-trinitrobenzene (TATB) crystals before and after the recrystallization in the ionic liquid-DMSO co-solvent system. .

The same explosive used in deep oil exploration may perform better and safer the next time it’s used to chip away rock in search of oil.

Researchers at the Laboratory have discovered a method to dissolve the explosive TATB (1, 3, 5-Triaminio-2,4,6-trinitrobenzene) to improve its quality and performance once it is reverted back to a solid.

TATB is a molecular solid with an extensive hydrogen bond network, which makes it nearly impossible to dissolve in any conventional solvent system. It is a key explosive used in experiments at the Laboratory, the departments of Energy and Defense and in deep oil exploration.

"The solubility of TATB is very important in order to recrystallize TATB after its bulk production, to improve the crystal quality and the chemical purity," said T. Yong-Jin Han, lead author of a paper that appears on the cover of the January issue of the New Journal of Chemistry.

Most explosives belong to a general class of materials called molecular crystals, which have become important building blocks in a number of other applications ranging from drugs, pigments, agrochemicals, dyes and optoelectronics. Many of these materials, including TATB, are bound together by a strong network of hydrogen-bonds. This extended network often makes these materials nearly insoluble in common organic solvents, leading to poor quality and limited crystal sizes, which in turn hinders progress in many technological applications.

But in the new research, the team, including Phiilip Pagoria, Alexander Gash, Amitesh Maiti, Christine Orme, Alexander Mitchell and Larry Fried, found that by using EMImOAc (3-ethyl-1-methylimidazolium acetate, a room temperature ionic liquid) as the solvent, TATB could be dissolved readily. At that point, it can be reverted back to a solid crystal by the addition of a proton source. (Room temperature ionic liquids are a special type of molten salt that are liquid under the boiling point of water — 100 degrees Celsius).

Through this process, Han observed a noticeable difference in the quality of the TATB crystals.

"TATB’s crystal quality must be improved after bulk production to advance its performance and safety," Han said. " In order to do this, we need to dissolve TATB in an ideal solvent, which will give us the maximum flexibility during the crystallization process. Before ionic liquid came into the picture, the reprocessing of the bulk material by crystallization was not a viable option, since the conventional organic solvents did not dissolve TATB to any significant amounts."

In earlier research, the team had investigated other ionic liquids to dissolve TATB (Maiti et al. Phys. Chem. Chem. Phys., 2008, 10, 5050), but reverting TATB back to a solid was more complicated than using the new solvent.

Ultimately, a high quality crystal of TATB with fewer defects and voids (thus higher density) may provide better performance, and less sensitivity to shock initiation. In addition, controlling the size distribution of TATB crystals is an important aspect of processing TATB for many applications.

This work was supported under the Transformational Materials Initiative (TMI), funded by the Laboratory Directed Research and Development Program.

To read more, go to the New Journal of Chemistry Website.