LLNL delivers ‘Scorpius’ pulsers amidst the pandemic

(Download Image)

(Download Image)

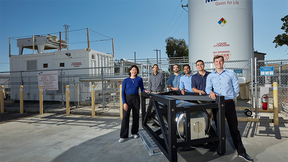

Brendan Riordan, Brian Marquez, Cas Casados and Sal Robles fabricate components for a pulsed power module. The team adhered to new work controls — including personal protective gear and limited time in proximity — to mitigate risks related to COVID-19.

Lawrence Livermore National Laboratory (LLNL) researchers completed assembly and qualification of 16 prototype high-voltage solid state pulsed-power drivers (pulsers) in July, enabling the project to still meet the delivery schedule for the Scorpius radiography project, despite COVID-19 workplace restrictions. Eight of those pulsers were shipped to Sandia National Laboratories (SNL) and eight remained on-site at LLNL, all for use in integrated subsystem testing.

Scorpius is a multi-lab partnership with the objective of delivering four-pulse radiography to support the national effort to modernize the U.S. nuclear stockpile. Once deployed underground at the Nevada National Security Site (NNSS), Scorpius will generate four high-fidelity radiographic images of contained subcritical experiments utilizing special nuclear material.

Los Alamos National Laboratory (LANL) leads the national effort to design and build Scorpius, leveraging expertise from LLNL, NNSS and SNL. LLNL’s innovative solid-state pulsed-power technology will drive the injector and accelerator components in Scorpius. Pulsed power involves the gradual accumulation of energy into capacitors, followed by a very quick release of this energy. The pulsers are designed to make four 25,000-volt pulses, which will energize a 22.4 MeV injected electron beam. That beam will then collide with a metal target, generating X-rays capable of penetrating experimental test objects and recording required images.

Unlike older pulsed-power technologies that rely on water-filled stainless steel pipes to create an electrical pulse, the technology LLNL used in the pulsers relies on solid-state integrated circuits. This approach gives Scorpius the unique ability to change pulse width and pulse spacing, offering experimenters tremendous latitude in tailoring the radiographs to individual experiments.

“The capability we are developing is a real step forward in stockpile diagnostics when using special nuclear material,” said Brian Guidry, LLNL electronic engineer and senior team leader.

LLNL committed to build and deliver 16 prototype pulsers so that integrated testing with the accelerator and injector cell sub-assemblies from partner laboratories could begin. Pulser assembly work was underway when the COVID-19 shelter-in-place disrupted activities last March.

“Suddenly, we were at a standstill,” Guidry said. “So the team members rolled up their sleeves, jumped into the work and figured out how to complete the prototype build.”

Production team leader Chris Bishop and chief scientist Saeed Assadi joined Guidry in implementing new Laboratory work controls to mitigate risk amid the pandemic, including use of N95 masks and creating safe distances between each other.

“I really could not be prouder of the team and their efforts,” Guidry said. “We have now shipped the last pulser. This was a critical delivery on this high-profile project that enabled our partners to move forward with the work they need to do.”

The next step is testing the pulsers with prototype accelerator cells delivered by Los Alamos, a project task set for completion in early 2021. As the design and testing process culminates in the final design, Livermore will have to manage delivery of 1,000 pulsers required for the Scorpius installation.

“We think about the pulsers and accelerator cells as a system now, rather than independent components,” Guidry said. “Our next design challenge is to create a system that can be replicated at the required production scales. I know the team is up to it.”

-- Suzanne Storar

Contact

Nolan O'Brien[email protected]

925-422-3399

Related Links

LANLTags

Global SecurityFeatured Articles