Perfecting the spider's art to support NIF targets

(Download Image)

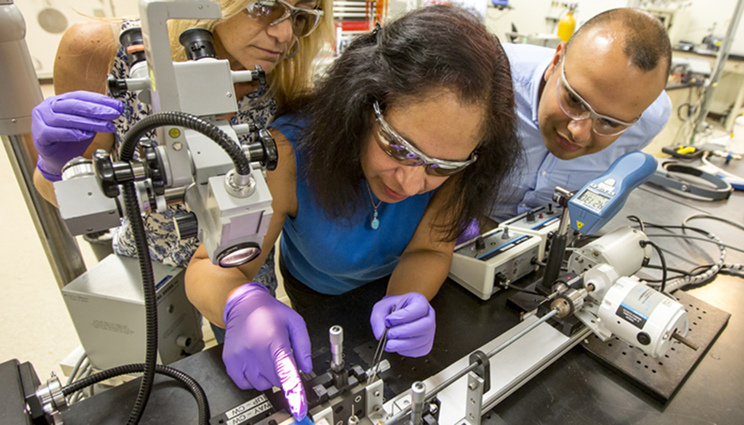

From left, Chantel Aracne-Ruddle, Alicia Calonico-Soto and Xavier Lepró weave carbon nano-webs to support NIF target capsules. Photo by Jason Laurea/LLNL

(Download Image)

From left, Chantel Aracne-Ruddle, Alicia Calonico-Soto and Xavier Lepró weave carbon nano-webs to support NIF target capsules. Photo by Jason Laurea/LLNL

Materials scientist Xavier Lepró can’t grow his "spider webs" fast enough to swing from skyscrapers like Spiderman, but he can best another web-maker, Mother Nature, when it comes to consistency.

Lepró helped pioneer the spinning of spider-silk-like yarns for use in suspending target capsules inside NIF hohlraums. These yarns are even stronger than the silks spun by the technology’s inspiration, real-life spiders. The ultrathin fibers are being developed by a team led by Michael Stadermann, group leader for the Lawrence Livermore National Laboratory Target Fabrication Group’s science and technology arm.

The team spins carbon nanotube yarns with diameters on the scale of a few microns, or millionths of a meter. Like spider silk, the NIF yarns are stronger than steel and so gossamer thin as to be almost invisible. Their goal is to field the fibers as a capsule-support alternative to the "tents" traditionally used to hold the peppercorn-size capsules inside NIF hohlraums (see "How NIF Targets Work").

Stadermann’s group sought a material that would provide both low contact and staunch support for the capsules. The current supports are nanometer-thick membranes that partially wrap around the capsule; experiments revealed that these "tents" induce perturbations at the point of contact that can interfere with NIF implosions (see "Studying Effects of Target ‘Tents’ on NIF Implosions").

The team wanted an alternative that would minimize the perturbations by reducing the contact surface between the support and capsule but still hold the capsule firmly in place at four points, a technical challenge. They required a material that was strong and thin like wire and capable of supporting 100,000 times its weight without breaking or yielding during assembly and handling. When seeking a material as strong as steel yet light as a feather, the connection to spider silk was obvious.

NIF was one of a number of scientific organizations that tried running a spider "farm" to harvest actual spider silk for experiments. In NIF’s case, the territorial arachnids proved hard to sustain, and there also were quality-control issues.

As Lepró explained: "We need a material we can rely on. That is not spider silk, because spider silk properties change with the mood of the spider."

When Lepró came to the Lab in 2016 as a postdoc fellow from the University of Texas at Dallas with experience in nanotechnology, Stadermann decided to harness his ability working with nanometric and micrometric threads to try synthesizing an alternative fiber for use in NIF targets.

Lepró, along with Chantel Aracne-Ruddle and Alicia Calonico-Soto, a NIF & Photon Science Directorate Summer Scholar, begin with what they dubbed a "carbon nanotube forest." These are arrays of tubes approximately 12 nanometers (0.00000047 inches) in diameter, Lepró said. "They grow in such a way that the carbon nanotubes arrange themselves perpendicular to the substrate, like a bamboo ‘forest’ on a field, where each bamboo will be equivalent to a nanotube."

By pulling from the edge of the nanotube "forest," the team assembles bundles of hundreds of individual nanotubes into threads. They then weave millions of the nanotube threads into a yarn, in much the same way that weavers have spun wool to make yarn throughout the centuries. "This is ultra-high tech meeting ultra-low tech," Stadermann said.

The product is a round "knit" tube composed of millions of carbon nanotubes twisted together. Each nanotube is made solely of carbon atoms and is stronger than steel when normalized by weight. The yarns are flexible, like spider silk, with the added advantage of being thermally and electrically conductive. Stadermann says the carbon nanotube yarn is among the thinnest fibers his team has ever made. The diameter of carbon nanotube yarn is similar to the diameter of a typical spider-silk thread, Lepró confirmed.

The first test of the impact of the nanotube yarn was performed this month in a hydrogrowth radiography experiment on NIF. The test had encouraging results that will be fully analyzed in the coming months.

--Lisa Petrillo

Contact

Breanna Bishop

Breanna Bishop

[email protected]

(925) 423-9802

Related Links

“How NIF Targets Work”“Studying Effects of Target ‘Tents’ on NIF Implosions”

Tags

Lasers and Optical S&TLaser Materials

Lasers

National Ignition Facility and Photon Science

Physical and Life Sciences

Featured Articles