Researchers address the challenges in creating carbon nanotubes on metal foil

(Download Image)

(Download Image)

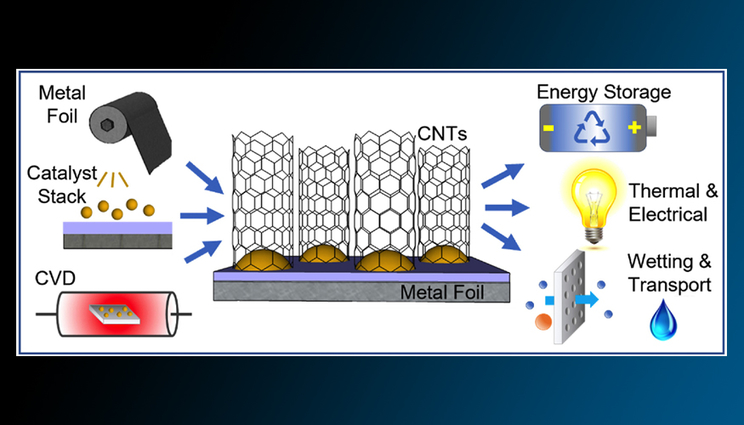

Illustration depicting (left) key steps to scale-up growth of vertically-aligned carbon nanotubes on metal foils for various applications, such as energy storage, thermal interfaces, and wetting and fluidic devices.

Carbon nanotubes (CNTs) provide extraordinary electronic, thermal, mechanical, and transport properties, among many other benefits. Vertically aligned CNT (VACNT) forests have promising potential applications ranging from energy storage to multifunctional fiber production. While CNTs are traditionally made on substrates such as silicon, the process is not compatible with large-scale manufacturing. Metal substrates offer a promising route to overcome scale-up limitations, but they present additional challenges, such as increased roughness and reactivity at high temperatures.

Lawrence Livermore researchers have identified the hurdles in each step of the CNT production process using metal foil substrates and provided a summary of efforts towards overcoming the issues. First, metal selection must account for a variety of chemical, physical, and morphological features. The team identified recent studies, including one completed at LLNL, that demonstrated successful growth of CNT forests on various 2D metal substrates and provided the list of relevant properties and outcomes for metals such as nickel, Inconel, and stainless steel. They found metal composition and surface smoothness to be significant parameters to consider with working with metal foil compared to silicon.

The team also found that achieving the desired VACNT product required careful engineering of barrier layers and catalysts. In some cases, metal foils yielded wide diameter, multi-walled CNTs on economical substrates like stainless steel without depositing barrier and catalyst layers, offering the potential to greatly simplify the manufacturing process. On the other hand, coating the metal foil with a barrier layer was necessary to obtain well-graphitized, small-diameter single-walled VACNTs. These successful growths highlighted the feasibility of transitioning even the most challenging VACNT products to the more flexible substates.

This research supports continued progress towards the scalable and economical creation of CNTs, with applications in energy storage, electronics, smart textiles (such as LLNL’s second skin), and membranes.

This work received support from the Laboratory Directed Research and Development program (21-LW-020).

[K. Moyer-Vanderburgh, S.J. Park, F. Fornasiero, Growth of carbon nanotube forests on flexible metal substrates: Advances, challenges, and applications, Carbon (2023), doi: 10.1016/j.carbon.2023.02.054.]

–Physical and Life Sciences Communications Team