LAB REPORT

Science and Technology Making Headlines

Aug. 12, 2016

Studying the metallic form of hydrogen can lead to insights into Jupiter’s interior.

Pressure is on to make metallic hydrogen

Using one of the most advanced laser facilities in the world — the National Ignition Facility at Lawrence Livermore — scientists zap hydrogen to produce high pressures and temperatures. Though the conclusions of this experiment are not yet published, LLNL physicist Gilbert says, “we have some really beautiful results.”

The first experiment to show evidence of liquid metallic hydrogen was performed at Lawrence Livermore in the 1990s. A team of physicists, including William Nellis, now at Harvard, used a sophisticated gunlike apparatus to shoot projectiles into hydrogen at blisteringly fast speeds. The resulting hydrogen briefly conducted electricity.

These experiments face hurdles of their own — it’s a struggle to measure temperature in such systems, so scientists calculate it rather than measuring it directly. But many researchers are still convinced by these results.

“It’s certainly difficult to tell if something is a metal or not at such high temperature,” Collins said.

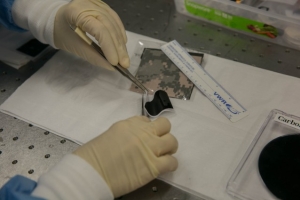

LLNL researcher Ngoc Bui demonstrates the flexibility of a carbon nanotube membrane.

Keeping the viruses out

Lawrence Livermore National Laboratory scientists are using carbon nanotubes to create a barrier that would be impenetrable to chemical and biological agents, but still water-permeable. The result could make suits designed to protect against chemical and biological threats more comfortable — and effective — for long-term wear.

Soldiers are already issued protective suits to deal with chemical or biological attacks, suits that are thickly walled to keep out bacteria, viruses and chemical agents. With that protection comes a lack of "breathability" — the ability of a garment to expel sweat built up during strenuous activity. This makes suits increasingly uncomfortable the longer the wearer has them on.

LLNL scientists are working to integrate carbon nanotubes into military uniforms, developing a fabric that will let water pass but not chemical agents and microscopic organisms come through.

Synchrotron light sources are ideal for probing into the smallest of details in a range of materials.

Revealing materials' secrets

Scientists are flocking to synchrotron light sources to reveal materials’ secrets.

With the ability to probe a wide range of materials, these powerful light sources can trace the smallest of details. Lawrence Livermore material scientist Tony Van Buuren points to another unmatched synchrotron feature - exceptional brilliance or beam intensity. The large number of X-ray photons emitted in fleeting bursts of synchrotron light enables researchers to make ultrafast time-dependent measurements, an ideal way to capture nanosecond snapshots of proteins and other molecules undergoing rapid changes.

With recent progress in controlling synchrotron radiation, scientists also can work with very fine beams of X-rays. This gives researchers a high degree of spatial control over their experiments, opening the door to new types of microscopy that provide nanoscale structural information along with detailed chemical maps.

All of these unique capabilities of synchrotron radiation offer unprecedented ways of peering deep into the interior of catalysts, battery materials, ancient artifacts and other specimens without having to first isolate them from their natural or technologically relevant environments.

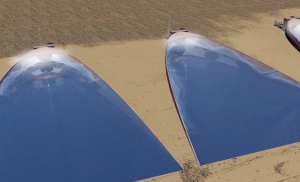

Digital Glass™ can provide new ways to harvests sunlight. Phots courtesy of Giant Leap Technologies.

Here comes the sun

Lawrence Livermore recently collaborated with Giant Leap Technologies to produce 3D printed microfluidic solar cells that would generate more power than current solar power plants, with less cost and less material.

The project is being funded by a grant from the Department of Energy (DOE) and this week the department has announced their own 3D printing project, this time directed at wind turbines.

DOE’s Advanced Manufacturing Office is a division dedicated to the development of environmentally and economically sustainable technology using the newest manufacturing methods – such as 3D printing. Working with partners including industry representatives, small businesses and universities, it has been responsible for the creation and commercialization of hundreds of energy-saving industrial technologies.

Lawrence Livermore materials scientist Joseph McKeown uses the Lab’s dynamic transmission electron microscope (DTEM) to investigate rapid alloy solidification. The DTEM allows direct imaging of the solid-liquid interface as it moves at high velocities. Photo by Julie Russell/LLNL

Dynamically solid

Under a $500,000 grant from the National Science Foundation, engineers at the University of Pittsburgh will use the Dynamic Transmission Electron Microscope (DTEM) at Lawrence Livermore National Laboratory to observe rapid-phase transitions in aluminum alloys under laser and electron-beam processing.

The study is expected to deliver valuable data and computer-modeling capabilities to the metal-additive manufacturing industry.

With nanosecond and microsecond temporal resolution, the DTEM will enable the university’s engineering students to observe various rapid transitions of aluminum alloys during welding, joining and other processes — in essence seeing the transitions from liquids to solids.