LAB REPORT

Science and Technology Making Headlines

Oct. 7, 2016

Lawrence Livermore received the 16-chip IBM TrueNorth platform earlier this year.

Deep thinking

Compared to today, the super computers of tomorrow will work more like a human brain. For humans, that means deep learning can come from the depths of these brain-like computers.

The IBM TrueNorth design may better support the goals of neuromorphic computing that focus on closely mimicking and understanding biological brains.

Understanding brain function better is an important element for neuromorphic computing research but so is developing real-world applications. Lawrence Livermore National Laboratory has purchased a True-North-bases system to do just that.

Current protective military uniforms are based on heavyweight full-barrier protection that cannot meet the critical demand of simultaneous high comfort breathability and protection from biological and chemical agents.

Getting smart with uniforms

A new project funded by the Defense Threat Rudcution Agency's Joint Science and Technology Office and conducted by a team of Lawrence Livermore National Laboratory (LLNL) scientists have created “second skin,” a new material that is breathable and protects against biological and chemical threats.

Second skin blocks harmful agents such as sulfur mustard (blister agent), GD and VX nerve agents, toxins such as staphylococcal enterotoxin and biological spores such as anthrax.

Current protective military uniforms are based on heavyweight full-barrier protection or permeable adsorptive protective garments that cannot meet the critical demand of simultaneous high comfort and protection and provide a passive rather than active response to an environmental threat.

The LLNL team fabricated flexible polymeric membranes with aligned carbon nanotube (CNT) channels as moisture conductive pores. The size of these pores (less than 5 nanometers, nm) is 5,000 times smaller than the width of a human hair.

Lawrence Livermore worked with Hoya Corporation and Schott Glass Technologies Inc. to develop a fabrication and production method for the laser glass needed for the National Ignition Facility, and the Lab teamed up with the manufacturers to scale up production.

Calling all entrepreneurs

The Department of Energy recently launched Build4Scale, which helps entrepreneurs build their clean energy products by providing training on manufacturing fundamentals like material selection, design for assembly and working with production partners.

The training program will help cleantech entrepreneurs identify manufacturing challenges early in the development process. When these challenges are better understood and easier to navigate it can save time and capital for clean technology startups as they focus primarily on attracting industry partners and investors.

Lawrence Livermore is leading the development of the Build4Scale training program, and will collaborate with more than a dozen partners to develop the curriculum.

Lawrence Livermore researchers and collaborators studied a regulatory element for the gene controlling bone pressure loading and unloading.

Boning up on genes

Researchers from Lawrence Livermore National Laboratory and collaborators are investigating a regulatory element for the gene controlling bone mechanoadaptation.

Over time, pressure loaded on the skeleton builds bone mass while bone mass is lost from disuse. The sclerostin (Sost) gene is a negative regulator of bone formation that responds to pressure loading and unloading known as mechanoadaptation.

The study hypothesized that the non-coding enhancer ECR5 was the primary regulatory element working like a light switch telling the Sost gene whether it should turn on or off during loading and unloading.

Sost helps stop bone growth from getting out of hand so bones are not continuously growing larger and larger. When you do not have Sost expression, bone is resistant to disuse and does not lose mass.

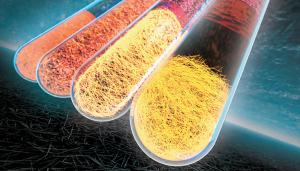

An illustration of the separation process from a mixture of various copper nanocrystal shapes (two tubes to the left) to pure nanowires and nanoparticles (two tubes to the right)

Pure and simple: High yield copper nanowires

Cell phones and Apple watches could last a little longer due to a new method to create copper nanowires.

A team of Lawrence Livermore scientists have created a new method to purify copper nanowires with a near-100 percent yield. These nanowires are often used in nanoelectronic applications.

The research shows how the method can yield large quantities of long, uniform, high-purity copper nanowires. High-purity copper nanowires meet the requirements of nanoelectronic applications as well as provide an avenue for purifying industrial-scale synthesis of copper nanowires, a key step for commercialization and application.

Metal nanowires hold promise for commercial applications such as flexible displays, solar cells, catalysts and heat dissipators.