LAB REPORT

Science and Technology Making Headlines

Oct. 12, 2018

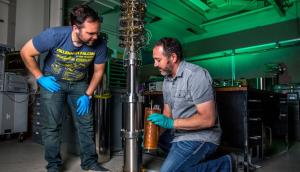

LLNL postdoc Nathan Woollett and LLNL staff scientist and ADMX co-spokesman Gianpaolo Carosi work on the cryostat system in which LLNL places its test microwave cavity. Photo by George Kitrinos/LLNL

Kept in the dark

Researchers at Lawrence Livermore are in search of a dark secret: Where is the dark matter that makes up 95 percent of the universe. We see only 5 percent of all matter that makes up all the galaxies and stars, planets, black holes, quasars, pulsars, neutrinos — as well as humans and all other life on Earth. The rest is dark matter.

Lawrence Livermore scientists are searching for axions -- low-mass particles -- that they think could solve what dark matter is made up of.

The Axion Dark Matter eXperiment, or ADMX is the most sensitive scientific instrument of its kind. If ADMX confirms the existence the axion, it could finally explain the massive cosmic mystery of dark matter.

Unlike normal matter, we don't know what dark matter is made of. Scientists are using the best theories about dark matter to build elaborate detectors, trying to catch the phantom by whatever glimmer it leaves behind.

ADMX consists of a detector in a tank about four meters high. It features a very large superconducting magnet and a microwave cavity and works similar to a radio receiver. It’s like if the researchers had a radio that’s searching for a radio station, but they have no idea about its frequency — so they are turning the knob, slowly, trying to hear a signal when the frequency is just right.

LLNL researchers have developed machine learning algorithms capable of processing the data obtained during metal 3D printing in real time. Image by Jeannette Yusko and Ryan Chen/LLNL

Neural network metals with 3D parts

For years, engineers at Lawrence Livermore National Laboratory have used sensors and imaging techniques to analyze the physics and processes behind metal 3D printing to build high-quality metal parts the first time, every time.

They are now leveraging machine learning to process data obtained during 3D builds in real time, detecting within milliseconds whether a build will be high quality. More precisely, they are developing convolutional neural networks (CNNs), a type of algorithm commonly used to process images and videos, to predict whether a part will be good by looking at as little as 10 milliseconds of video.

Until now, analysis of sensor data taken while 3D printing a metal parts was done after the part was finished and it was expensive. And part quality could only be determined long after, explains principal investigator and LLNL researcher Brian Giera. With parts that take days to weeks to print, CNNs help engineers better understand the printing process and let them correct or adjust the process in real time if necessary before the part is built.

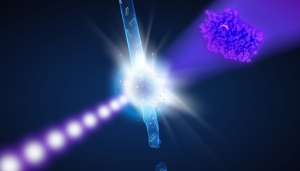

This artist’s rendering depicts a previously unknown structure of an enzyme responsible for antibiotics resistance. The pioneering work demonstrates that the new European XFEL research facility can speed up experiments by more than an order of magnitude. Image by Lucid Berlin/DESY

Zeroing in on an enzyme

An international collaboration led by DESY and consisting of more than 120 researchers including those from Lawrence Livermore have unveiled results of the first scientific experiments at Europe's new X-ray laser, European XFEL.

The pioneering work not only demonstrates that the new research facility can speed up experiments by more than an order of magnitude, it also reveals a previously unknown structure of an enzyme responsible for antibiotics resistance.

The team chose a bacterial enzyme that plays an important role in antibiotics resistance. The molecule was isolated from the bacterium Klebsiella pneumoniae, whose multidrug-resistant strains are a grave concern in hospitals worldwide. Two years ago, even a "pandrug-resistant" strain of Klebsiella pneumoniae was identified in the U.S. as unaffected by all 26 commonly available antibiotics.

The bacterium's enzyme is present in all strains. It works like a molecular pair of scissors, cutting lactam rings of penicillin-derived antibiotics open, thereby rendering them useless. The scientists investigated a complex of the enzyme from the non-resistant, "wild type"’ of the bacterium with avibactam bound to the enzyme's active center, a structure that has not been analyzed before.

A sample of microarchitectured graphene aerogel, made from one of the lightest materials on Earth, sits atop a flower.

Grappling with graphene

Engineers from Virginia Tech and Lawrence Livermore have developed a novel way to 3D print graphene at a resolution far greater than ever before. This achievement paves the way for graphene's use in smaller objects and in more varied shapes than what was previously possible.

For some time, researchers have been searching for efficient and inexpensive ways to fabricate graphene -- a carbon-based material valued for its strength, light weight and electrical conductivity. However, to date, they haven’t been able to develop the material at a size large enough to support some of the objects they seek to build with it.

Previously, researchers could only print graphene -- a single layer of carbon atoms organized in a hexagonal lattice -- in 2D sheets or basic structures. With the new technique, the team achieved sizes an order-of-magnitude (10 times) smaller than previous methods while making far more complicated shapes.

LLNL computer scientists (from left) Todd Gamblin and Greg Becker met with HPC Application expert Massimiliano Culpo at the École polytechnique fédérale de Lausanne (EPFL) in Lausanne, Switzerland. Culpo is an EPFL scientist and longtime Spack contributor who uses Spack to manage software on EPFL’s supercomputers.

Spack attracts

Spack, a Lawrence Livermore National Laboratory-developed open source package manager optimized for high performance computing (HPC), is making waves throughout the HPC community, including internationally, as evidenced by a recent tour of European HPC facilities by the tool’s developers.

Despite its niche status, Spack (short for Supercomputer PACKage manager), is one of the most popular pieces of software the Lab has ever released to the GitHub open source community. Described by its developers as “an app store for supercomputers,” Spack was started by LLNL computer scientist Todd Gamblin in 2013 and has quickly become the go-to package manager at LLNL and Argonne, Oak Ridge, Los Alamos and Sandia national laboratories, as well as Lawrence Berkeley’s National Energy Research Scientific Computing Center (NERSC).

Not only is it being used on the Department of Energy’s latest and greatest flagship systems, Oak Ridge’s Summit and LLNL’s Sierra, it’s also become the official deployment tool for the Exascale Computing Project, the “glue” for coordinating exascale software releases and deploying them to HPC facilities.