LAB REPORT

Science and Technology Making Headlines

Aug. 18, 2017

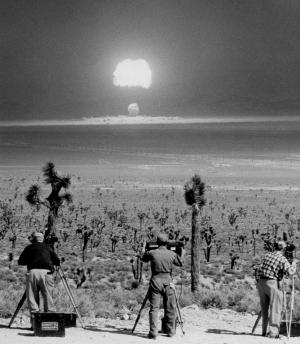

Movies of Operation Teapot is one of the recently declassified films available on YouTube.

Old test films are 'da bomb'

The U.S. stopped nuclear testing a quarter-century ago, but it continues to refurbish aging devices, and needs accurate predictions of how those weapons would perform. At the Lawrence Livermore National Laboratory, nuclear weapons physicist Greg Spriggs has been tasked for more than a decade with writing and updating computer code to predict fallout.

He’s had difficulties using test films created more than half a century ago under extreme circumstances on sometimes unstable stock, then stored under varying conditions. The answer, Spriggs realized more than a decade ago, was to move from analyzing copies of tests to re-examining the original tests themselves.

Trouble was, his models wouldn’t agree with the data — so as a “sanity check,” he convinced his supervisor to let him digitize about a dozen of the estimated 10,000 such films that exist to check cloud heights and dimensions. When data and models still didn’t align, something not entirely unexpected occurred: His boss gave him the job of reanalyzing all the films to obtain usable data.

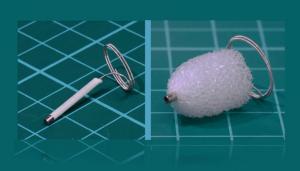

Microstructures of two different foam materials. At left, a traditional open-cell stochastic foam, and a right, a 3D printed foam with the face-centered tetragonal lattice structure.

3D printing foams up

Foam is used in an endless array of product applications. It is an essential component in a large number of industries, including automotive, aerospace, electronics, sports, biomedical and packaging. 3D printing offers benefits that traditional manufacturing techniques lack, such as the ability to manufacture unique or custom components in low volumes and for low cost.

Lawrence Livermore material scientists recently 3D printed foam and found that it actually works better than traditionally manufactured foam products in terms of durability and long-term mechanical performance.

Many companies and organizations around the nation have been exploring the potential for 3D printing with foam.

Research by Lawrence Livermore scientists shows that exposure to antibacterial chemicals common in personal care products such as soap and lotions can transfer from mother to offspring and cause adverse effects.

From mother to child

Children could gain weight if their mother used antibacterial soap during pregnancy, a new study warns.

Researchers at Lawrence Livermore National Laboratory found that a mother’s everyday exposure to the chemical triclocarban (TCC), the substance found in antibacterial soaps and lotions, could also lead to 'irreversible' damage in vital organs.

In studies on mice, they found that TCC passed through the placenta and breastfeeding from mother to child.

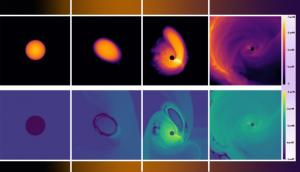

For the first time, scientists have conducted thermonuclear measurements of nuclear reaction cross-sections under extreme conditions like those of stellar interiors.

It’s written in the stars

Researchers at the Lawrence Livermore National Ignition Facility have recreated the interiors of heavy stars.

Stars are our model for creating nuclear fusion here on Earth, with fusion power often promoted as "harnessing the power of the sun." However, there are some surprising gaps in understanding of what's going on inside stars. That's partly because what’s going on there is inferred based on the elements and particles that reach the solar surface, and partly because finding ways to test theoretical models of fusion reactions is so difficult.

Researchers describe using the National Ignition Facility, built to study fusion using a giant laser, as a model for the interior of heavy stars. The results show that, despite their limitations, earlier efforts to understand stellar fusion were on the right track.

Hydrogen gas bubbles evolve from water at tantalum disulfide electrocatalyst surfaces. Catalytic activity in layered metal dichalcogenides like these is usually limited to edges, but new work reports on new materials that also can generate hydrogen at the surfaces. Image by Ryan Chen/LLNL

It’s something in the water

Lawrence Livermore scientists have developed a technique that helps extract hydrogen from water efficiently and cheaply.

Hydrogen can be used as a clean fuel in fuel cells, which produce power, with water and heat as the only byproducts. As a zero-emission fuel, the hydrogen can be recombined with oxygen to produce electric power on demand, such as onboard a fuel-cell vehicle.

The Livermore team and collaborators turned to electricity to produce clean hydrogen fuel by splitting water molecules, which are made of oxygen and hydrogen atoms. The researchers discovered a new class of cheap and efficient catalysts to facilitate the water splitting process.