LAB REPORT

Science and Technology Making Headlines

Aug. 10, 2018

Biogas is mostly methane, but it contains about 40 percent CO2, which is typically vented to the atmosphere.

Methane from microbes

Lawrence Livermore National Laboratory, in collaboration with Southern California Gas Co. and Stanford University, are using microbes to convert carbon dioxide directly to renewable natural gas.

The Department of Energy recently awarded the power-to-gas project $800,000. SoCalGas will provide co-funding of $400,000 in addition to $125,000 of seed funding it provided in 2017.

Using microbes to convert carbon dioxide directly to methane using renewable electricity is known as microbial electromethanogenesis (ME). ME more easily stores excess renewable electricity, significantly reducing the cost of producing renewable natural gas, increasing renewable natural gas availability and reducing carbon dioxide emissions.

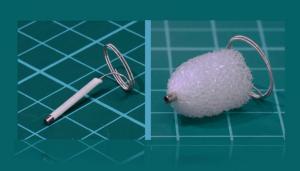

The FDA approved the use of IMPEDE®, a medical device used to treat bleeding abnormalities by deliberately blocking blood flow, which incorporates expanding shape memory polymer technology partly developed at LLNL. Image by Todd Landsman/Shape Memory Medical.

New device IMPEDEs blood flow

The Food and Drug Administration has approved the use of a medical device that could save lives.

The device, called IMPEDE embolization plug, deliberately blocks blood flow to treat bleeding abnormalities or other conditions, a procedure known as embolization. The device integrates expanding shape memory polymer technology that was partly developed at Lawrence Livermore.

Shape Memory Medical, a company founded by former LLNL scientist Duncan Maitland, was granted clearance for IMPEDE, which is designed to block or reduce blood flow in peripheral vasculature. The device can be "programmed" into a particular shape, made thin enough to fit in a catheter and expand to its former shape when exposed to stress or heat. The advantages of IMPEDE, Maitland said, include simple delivery through any diagnostic catheter, ease of navigation through twisted blood vessels and quick, stable embolization without compromising the vessel wall.

LLNL recently posted nuclear test films on YouTube.

New footage goes nuclear

Lawrence Livermore National Laboratory has posted newly declassified and digitalized films of past nuclear tests. The high quality of the footage and the extent of it provides a new perspective on the power of the world's most destructive weapons.

The videos are taken from a number of above and below-ground nuclear detonations that took place in the 1950s and '60s. They include multiple angles covering different aspects of each detonation, from the initial shockwave that propagates just after the reaction, to the glowing fireballs that morph into towering mushroom clouds, to the shock effects that roar outward from the epicenter at high-speed. Some of the films are even in color.

The Juniper test of Operation Hardtack I occurred on July 22, 1958. It was the last test at Bikini Atoll in the Pacific. The 65-kiloton device was detonated on a barge just a dozen feet above the waterline and it sent a cloud rocketing up 40,000 feet into the sky. The conditions that day resulted in a film that looks incredibly bleak, with the blast's mushroom cloud appearing charcoal black as it rises from the sea.

Lawrence Livermore National Laboratory researchers are part of a multi-lab team that has successfully designed, built and tested a portable diagnostic machine capable of probing inside metal parts as they’re being printed. Photo by Julie Russell/LLNL

X marks the spot

Metal 3D printing could revolutionize manufacturing but concerns over part quality and certification has kept many industries from jumping into the technology. From their perspective, the quality and certificate are critical, and essential for parts destined for automotive and aerospace applications.

To improve metal 3D-printed parts, researchers at Lawrence Livermore are examining the complex mechanisms that drive defects and limit part quality. They have also teamed with scientists at the SLAC National Accelerator Laboratory and Ames Laboratory to better understand 3D printing, looking into what leads to defects and how those flaws might be avoided.

The team is relying on X-ray imaging and diffraction to peer into metal parts as they’re being printed during the laser powder bed fusion (LPBF) process, a common metal 3D-printing approach. Building on years of research into the physics behind the process, LLNL researcher Nick Calta and his team have designed and built a portable diagnostic machine that probes the melt pool (where the laser meets the metal powder), along with the production of layers that eventually become a fully formed part.

Lawrence Livermore National Laboratory is preparing Sierra, the Lab’s next advanced technology high-performance supercomputer that will be used for stockpile stewardship.

Back at the supercomputing summit

Oak Ridge’s supercomputer Summit is in the top spot on the Top 500 ranking, but Lawrence Livermore is still coming in strong with Sierra earning the No. 3 spot.

Technology advocates in the United States will be even more pleased with the High-Performance Conjugate Gradient (HPCG) results, an alternative computing benchmark now also being considered in these semi-annual rankings. On that list, Summit comes in at No. 1 and Sierra comes in at No. 2.

The HPC benchmark is biased toward peak processor speed and number. And the HPC benchmark tests the computer’s ability to solve so-called dense-matrix calculations, which aren’t representative of many “sparse” real-world problems. HPCG was devised to remedy these shortcomings.