LAB REPORT

Science and Technology Making Headlines

Sept. 28, 2018

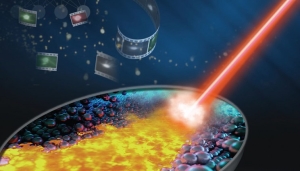

Researchers have developed machine learning algorithms capable of processing the data obtained during metal 3D printing in real time and detecting within milliseconds whether a 3D part will be of satisfactory quality. Image by Jeannette Yusko and Ryan Chen/LLNL

I spy with my video eye

Leveraging machine learning techniques, Lawrence Livermore researchers are processing the data obtained during 3D builds in real time, giving them the ability to detect within milliseconds whether a build will be of satisfactory quality.

By developing convolutional neural networks (CNNs), a popular type of algorithm primarily used to process images and videos, the researchers can predict whether a part will be good by looking at as little as 10 milliseconds of video.

LLNL researchers developed the neural networks using about 2,000 video clips of melted laser tracks under varying conditions, such as speed or power. They scanned the part surfaces with a tool that generated 3D height maps, using that information to train the algorithms to analyze sections of video frames (each area called a convolution), a process that would be too difficult and time-consuming for a human to do manually.

Researchers were able to capture 3D images of microscopic cracks in nickel alloy caused by exposure to hydrogen, also known as hydrogen embrittlement. Credit: Dharmesh Patel/Texas A&M University College of Engineering

Cracking up

Microfractures in metal alloys, though impossible to see with the naked eye, can easily spread when exposed to water or hydrogen and lead to major problems in structures such as bridges, electrochemical and nuclear plants and hydrogen storage containers, leading to failures and expensive repairs.

In a recent study, researchers have, for the first time, captured 3D images of microscopic cracks in metal caused by exposure to hydrogen, also known as hydrogen embrittlement. Using the images, researchers identified 10 orientations of microscopic structures called grain boundaries that can deflect cracks and prevent damage caused by hydrogen.

The research relied on synchrotron-based X-ray diffraction and tomography techniques to investigate hydrogen-assisted cracks in nickel alloy. The result is a new method for analysis called 3D microstructure mapping that could aid materials processing methods aimed at blocking cracks from further propagation, strengthening metals and leading to longer lifespans for structures and components.

Lawrence Livermore is one of 10 companies recognized by Glassdoor for providing outstanding wellness perks to employees.

Pick your perk

Lawrence Livermore employees don’t just change the world — they also steer Dragonboats, talk to bestselling authors, chat with farmers and get massages on site. For these reasons and more, LLNL tops Glassdoor’s list of 10 companies that provide wellness perks to attract and retain quality employees.

The most popular phrase in LLNL’s Glassdoor reviews is “work life balance,” and it's easy to see why, with employee perks that include on-site fitness and wellness programs, author events, summer music concerts, employee discounts, seasonal farmers markets, networking activity groups, a childcare facility, passport events, quarterly blood drives, a charity run, support groups and complimentary on-site document shredding.

A sample of microarchitectured graphene aerogel, made from one of the lightest materials on Earth, sits atop a flower.

Light as a feather

Engineers have developed a new technique to 3D-print complex objects made of graphene, the semi-metal believed to be the strongest material known on Earth. With 200 times more strength than steel and high electrical and thermal conductivity, graphene has drawn a lot of attention lately. Scientists believe the material, if produced sufficiently, could lead to the development of improved batteries and sensors, as well as advances in aerospace and related sectors.

However, despite knowing the material and its immense potential, engineers have only been able to print graphene in 2D sheets or basic structures. The sheets retain graphene’s capabilities, but when they’re stacked to form a 3D structure, graphite, the lead in pencils, is formed — a material that doesn’t retain most of the graphene’s mechanical properties.

However, the latest technique developed by researchers from Virginia Tech and Lawrence Livermore enables 3D printing of fully capable graphene objects in any shape and size at a magnitude greater than ever before.

Spack is being used on Lawrence Livermore’s newest high-performance computing system, Sierra. The 125 petaFLOP/s machine supports the National Nuclear Security Administration’s stockpile stewardship mission.

Spack attack

Spack, a Lawrence Livermore-developed open source package manager optimized for high-performance computing (HPC), is making waves throughout the HPC community, including internationally, as evidenced by a recent tour of European HPC facilities by the tool’s developers.

Despite its niche status, Spack (short for Supercomputer PACKage manager), is one of the most popular pieces of software the Lab has ever released to the GitHub open source community. Described by its developers as “an app store for supercomputers,” Spack was started by LLNL computer scientist Todd Gamblin in 2013 and has quickly become the go-to package manager at LLNL and Argonne, Oak Ridge, Los Alamos and Sandia national laboratories, as well as Lawrence Berkeley’s National Energy Research Scientific Computing Center (NERSC).

Not only is it being used on the Department of Energy’s latest and greatest flagship systems, Oak Ridge’s Summit and LLNL’s Sierra, it’s also become the official deployment tool for the Exascale Computing Project, the “glue” for coordinating exascale software releases and deploying them to HPC facilities.