LAB REPORT

Science and Technology Making Headlines

May 13, 2022

Algal blooms in Lake Erie. Credit: Adobe Stock.

With better forecasts, comes safer water

Lawrence Livermore National Laboratory (LLNL) scientists and collaborators have used a new technique to better forecast the level of algal toxins that accumulate in Lake Erie every year.

Harmful algal blooms (HABs) are global phenomena, and in freshwater lakes and reservoirs, are caused by cyanobacteria of the genus Microcystis that produce microcystins, a suite of amino-acid-like toxins that are harmful to wildlife and humans. Understanding the environmental drivers that affect microcystin concentrations and developing forecasting capabilities are critical to protect human and environmental health and ultimately prevent future HABs.

The team used isotope labeling of the cyanotoxins to examine its degradation in Lake Erie. Using LLNL's NanoSIMS instrument, they confirmed that a small but highly active component of the microbiome was responsible for the degradation of the toxin.

Microcystins are a potent liver toxin and possible human carcinogen. Cyanotoxins can also kill livestock and pets that drink affected waters. Fish and bird mortalities also have been reported in water bodies with persistent cyanobacteria blooms. These blooms form when cyanobacteria, which are normally found in water, start to multiply very quickly. Blooms can form in warm, slow-moving waters that are rich in nutrients from sources such as fertilizer runoff or septic-tank overflows.

To mitigate human caused climate change, scientists are turning to 3D to provide sustainable energy harvesting and storage technologies. Image by Adobe Stock.

Harvesting energy in 3D

Scientists from Lawrence Livermore have developed catalytic electrodes using direct-ink writing, a 3D printing technology. The novel electrodes possess superior catalytic and electrochemical performance for use in several next-generation devices.

Global energy usage is predicted to rise by 50% by 2050, according to figures from the U.S. Energy Information Association. This huge increase in demand presents challenges for scientists and governments, as human activity has been intrinsically linked with global climate change and rising temperatures. To mitigate the effects of anthropogenic climate change, renewable and sustainable energy harvesting and storage technologies have been explored in the past few decades.

Electro-photochemical water splitting has emerged as a beneficial technology, where hydrogen is produced and can be used for energy storage due to its high energy density and total absence of carbon emissions. In this process, abundant, efficient, low-cost, and stable electrocatalysts are essential. To date, platinum has been commonly used as a catalyst for hydrogen evolution reactions due to its electrochemical inertness, high activity and near-thermoneutral binding energy.

A LLNL team is looking at existing natural gas infrastructure that may be used, upgraded or replaced to store hydrogen instead of natural gas. Image by Adobe Stock.

Hydrogen storage on tap

Mass adoption of hydrogen in place of natural gas is complicated by the difference in the two gases' chemical composition, meaning a one-to-one swap, using the same pipelines and storage techniques, is not technically feasible without important and expensive retrofitting.

The path to viable, safe, reliable and pure and blended hydrogen storage possibilities is the focus of a team of three U.S. national laboratories. Subsurface Hydrogen Assessment, Storage and Technological Acceleration (SHASTA) is a partnership between the National Energy Technology Laboratory, Pacific Northwest National Laboratory and Lawrence Livermore National Laboratory (LLNL) and will receive $6.75 million from the Department of Energy over three years to 2024.

The team is looking closely at existing natural gas infrastructure to determine how much can be used, how much can be upgraded, and how much must be replaced entirely.

“We can learn a lot from the natural gas industry. In California, gas is stored in a variety of ways; there are big surface tanks and the pipeline network, but the largest volume storage is in underground gas reservoirs,” said Technical Lab Lead at LLNL Joshua White.

By blending hydrogen with natural gas in the existing systems, current infrastructure can be reused and demand centers can be fed, but blending will only take you so far, White said.

A LLNL team demonstrated that a diagnostic incorporating surface acoustic waves — generated by laser-based ultrasound — could effectively and accurately evaluate laser melt lines and find defects in laser powder bed fusion metal 3D printing by scattering acoustic energy from melt lines, voids and surface features that can be quickly detected. Images by David Stobbe/LLNL.

Riding the wave

Researchers at LLNL have developed a novel all-optical ultrasound technique capable of conducting on-demand melt track characterization and fault detection in a common metal 3D printing process.

Lab researchers suggest a diagnostic employing surface acoustic waves, created by laser-based ultrasound, that may uncover microscopic surface and sub-surface faults in laser powder bed fusion (LPBF) metal 3D printing.

By scattering acoustic radiation from melt lines, voids and surface characteristics that can be immediately recognized, the team claims its technology can effectively and precisely analyze laser melt lines — the tracks where its laser liquefies metal powder in LPBF printing. Optical microscopy and X-Ray computed tomography were used to confirm the findings.

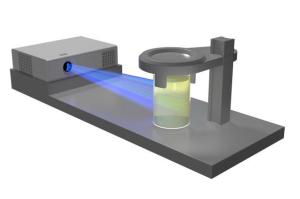

Nicknamed “The Replicator,” the breakthrough volumetric additive manufacturing technology takes computed tomography “views” of 3D objects from multiple angles, and projects these images into a photosensitive resin. Illustration by Jake Long/TID LLNL.

‘Replicating’ cartilage in space

NASA has awarded Lawrence Livermore National Laboratory (LLNL) and a private company with funding to develop LLNL’s revolutionary volumetric additive manufacturing (VAM) 3D printing technology to produce artificial cartilage tissue in space.

The award, one of eight projects selected by NASA’s In Space Production Applications program, will allow LLNL and Kentucky-based space life sciences company Space Tango to mature prototypes of the “replicator” technology — a ultrafast 3D printer co-developed by LLNL and the University of California, Berkeley — for bioprinting in microgravity on the International Space Station. The VAM printers are be expected to operate with little to no crew intervention.

The breakthrough VAM technology takes computed tomography “views” of 3D objects from multiple angles, and projects these images into a photosensitive resin. The resin cures at points where the accumulated, absorbed light energy exceeds the gel thresholds, and when the remaining liquid resin is drained, it produces 3D objects within seconds or minutes, much faster than traditional layer-by-layer 3D printing techniques.