LAB REPORT

Science and Technology Making Headlines

July 22, 2022

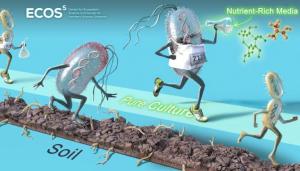

In a microbial footrace between different species, a fast-growing cell outperforms other cell types, as long as it enjoys the comforts of pure culture. But in real-world conditions, like those found in soil, (no shoes, no sugary energy drinks, rough ground), the slower cell types can gain the lead. Image by Northern Arizona University.

It’s all in the soil

To prevent dangerous levels of global warming, scientists say it won’t be enough to just stop burning fossil fuels that release carbon into the air. Because it’s virtually impossible for humanity to do that as fast as is now required, we also will need to pull carbon out of the air and secure it.

Plants are among the best tools we have to do this, since these living solar collectors already capture billions of tons of carbon dioxide each year from the atmosphere through photosynthesis. About half of that carbon winds up in roots and eventually the soil, where it can stay for hundreds to thousands of years.

Lawrence Livermore National Laboratory soil scientist Jennifer Pett-Ridge and her colleagues have an all-important task: Counting carbon atoms to make sure the entire concept, from plant cells to soils, actually works.

By placing gene-edited crops in special growth chambers and flooding them with CO2 containing a rare, heavy isotope known as carbon-13, the researchers will be able to see exactly how much carbon their plants are taking up, and where it’s winding up.

“In each of those pools, whether it’s leaves or roots or exudates or microbial cells or even microbial DNA, we can see that carbon-13,” Pett-Ridge said. “And we can quantify how much has been added and how much ends up in each pool.”

Pett-Ridge’s team also will be measuring an even rarer radioactive isotope known as carbon-14, which can be used to estimate both the age of soil carbon and how quickly it’s being cycled.

Rare earths bearing core sample drilled at La Paz, Arizona. Image courtesy of American Rare Earths Ltd/ photographer Dane Rhys.

Purified rare earths go their separate ways

Using naturally occurring and engineered proteins and bacteria, Lawrence Livermore National Laboratory scientists and collaborators will separate and purify rare-earth elements for use in the defense sector.

Under the Defense Advanced Research Projects Agency Environmental Microbes as a BioEngineering Resource program, the team was awarded an initial $4 million in funding R&D in Phase 1 with an option for up to an additional $9 million based on program performance in follow-on phases. The team will leverage advances in microbial and biomolecular engineering to develop a scalable bio-based separation and purification strategy for rare-earth elements (REEs) using under-developed domestic sources.

REEs are a set of 17 elements in the periodic table that includes the 15 lanthanides plus scandium and yttrium.

REEs are essential for American competitiveness in a high-tech economy because they are used in many devices important to the clean-energy industry and national security, including computer components, wind turbines, hybrid/electric vehicles, LCD screens and tunable microwave resonators. In the defense sector, they are used for lasers, precision-guided weapons, magnets for motors and other devices.

LLNL and Amazon Web Services will cooperate on a standardized software stack for HPC.

Stacking it up

Lawrence Livermore National Laboratory (LLNL) and Amazon Web Services (AWS) have signed a memorandum of understanding to define the role of leadership-class high performance computing (HPC) “in a future where cloud HPC is ubiquitous,” the two organizations said.

LLNL and AWS said they will explore software and hardware solutions spanning cloud and on-premises HPC environments, with the goal of establishing a common stack of open-source software components that can run equally well at both large HPC centers and on cloud resources.

“The cloud HPC market is growing, and clouds are becoming a viable way to run HPC jobs,” said computer scientist Todd Gamblin, who is leading the effort for LLNL. “More software is being developed for the cloud environment than for traditional HPC centers, and larger portions of our workflows are going to start looking like cloud software. So, we want to be in tune with mainstream software development, take advantage of this ecosystem and be able to deploy it easily, the way that clouds do.”

A LLNL team demonstrated that a diagnostic incorporating surface acoustic waves — generated by laser-based ultrasound — could effectively and accurately evaluate laser melt lines and find defects in laser powder bed fusion metal 3D printing. Images courtesy of David Stobbe/LLNL.

Defects are in the eye of the optical microscope

Lawrence Livermore (LLNL) researchers have developed a new all-optical ultrasound technique capable of performing on-demand characterization of melt tracks and detecting formation of defects in a popular metal 3D printing process.

In recent research, Lab scientists propose a diagnostic using surface acoustic waves, generated by laser-based ultrasound, that can reveal tiny surface and sub-surface defects in laser powder bed fusion (LPBF) metal 3D-printing. The team reported the system they developed can effectively and accurately evaluate laser melt lines — the tracks where the laser liquifies metal powder in LPBF printing—by scattering acoustic energy from melt lines, voids and surface features that can be quickly detected. The team validated the findings using optical microscopy and X-ray computed tomography (CT).

"We hope that this work demonstrates the potential for an all-optical ultrasound system capable of rapid, on-demand in situ characterization of LPBF processes and powders," said LLNL engineer and principal investigator David Stobbe. "The demonstrated laser-based ultrasound, surface acoustic wave system showed excellent sensitivity to surface and near-surface features, including breaks in the LPBF melt line, metal surface splatter and subsurface air voids."

Researchers and scientists have designed a fully decentralized stablecoin pegged to electricity, capable of transmitting electricity without wires.

It’s electric

A team of researchers and scientists from Lawrence Livermore National Laboratory utilized information theory and statistical mechanics to create the new type of cryptocurrency called the Electricity Stablecoin or E-Stablecoin.

This "fully collateralized stable coin" is pegged to a physical asset and its value is dependent on its utility.

Scientists say it is capable of transmitting energy as information without the need for any interconnecting wires or a grid-based transmission system.

A first of its kind, E-Stablecoin is the only cryptocurrency token designed as collateralized by a physical asset and fully decentralized since it uses the laws of statistical mechanics.