LAB REPORT

Science and Technology Making Headlines

Oct. 30, 2020

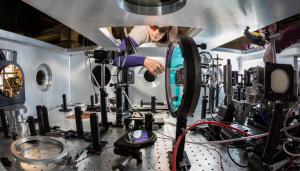

Researchers Felicie Albert (center) and Bradley Pollock prepare the Callisto laser system and set up for betatron X-ray experiments at the Lab's Jupiter Laser Facility, one of DOE’s LaserNetUS facilities.

Lasers for the masses

LaserNetUS, a network of facilities operating ultra-powerful lasers including those at Lawrence Livermore, has received $18 million from the Department of Energy (DOE) for user support.

Established in 2018 by DOE, LaserNetUS, is organized and funded by DOE’s Office of Fusion Energy Sciences. The network was created to provide vastly improved access to unique lasers for researchers and to help restore the United States’ once-dominant position in high-intensity laser research. This new funding, distributed among 10 partner institutions and including $1 million for user support, will continue and expand LaserNetUS operations for three years.

The initiative includes Lawrence Livermore (LLNL), home of the Jupiter Laser Facility (JLF). According to JLF Director Robert Cauble: “LLNL created JLF (the fifth highest-energy laser in the U.S.) about a dozen years ago to give researchers at LLNL, other labs and universities access to lasers with capabilities well beyond typical university-class laser systems, providing time to try out new experimental ideas, develop novel techniques and train students.”

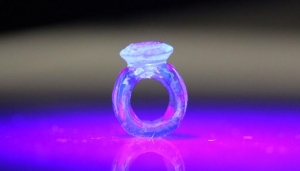

Using a custom volumetric additive manufacturing 3D printer, Lawrence Livermore researchers were able to build tough and strong, as well as stretchable and flexible, objects nearly instantly from thiol-ene resins. Photo by Maxim Shusteff/LLNL.

In a class of its own

Researchers at Lawrence Livermore National Laboratory (LLNL) have adapted a new class of materials for their groundbreaking volumetric 3-D printing method that produces objects nearly instantly, greatly expanding the range of material properties achievable with the technique.

The class of materials adapted for volumetric 3D printing are called thiol-ene resins, and they can be used with LLNL's volumetric additive manufacturing (VAM) techniques, including Computed Axial Lithography (CAL), which produces objects by projecting beams of 3D-patterned light into a vial of resin. The vial spins as the light cures the liquid resin into a solid at the desired points in the volume, and the uncured resin is drained, leaving the 3D object behind in a matter of seconds.

Previously, researchers worked with acrylate‐based resins that produced brittle and easily breakable objects using the CAL process. However, the new resin chemistry, created through the careful balancing of three different types of molecules, is more versatile and provides researchers with a flexible design space and wider range of mechanical performance. With thiol-ene resins, researchers were able to build tough and strong, as well as stretchable and flexible, objects, using a custom VAM printer at LLNL.

A shuttered asbestos mine site on San Benito Mountain, near Coalinga, California. Photo by Roger Aines/LLNL.

Battling climate change with asbestos

Asbestos is a natural mineral known to cause lung cancer called mesothelioma. But reseachers have found a much better use for it; the carcinogenic mineral can be used as a new method to alleviate climate change.

Similar to forests, asbestos can be used as a carbon sink to absorb atmospheric carbon dioxide. After studying samples, scientists believe that closed asbestos mines have the potential to absorb carbon dioxide on a global scale.

Asbestos in old sites does not have to be touched to absorb carbon, so scientists can avoid unnecessary exposure to the mineral. When asbestos compounds absorb carbon dioxide, it creates magnesites.

Roger Aines of the Carbon Initiative at Lawrence Livermore National Lab said that the use of old asbestos mines is a great “opportunity that could remove enormous amounts of CO2.” Researchers are still figuring out how they can effectively and affordably dig up minerals, potentially including asbestos, specifically for the purpose of drawing down vast amounts of greenhouse gas from the atmosphere.

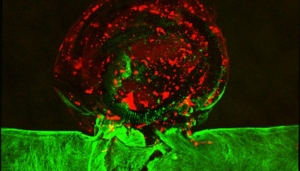

Using 3D printing, an LLNL team replicated an aneurysm in vitro and performed an endovascular repair procedure on the printed aneurysm. The green areas depict the endothelial cells and the red indicates the formed clot. Photo by Elisa Wasson.

Living brain aneurysm in 3D

Scientists have created a living brain aneurysm using 3D-printed human brain cells and blood.

Caused by a weakening in the artery walls, brain aneurysms are characterized by a “ballooning” or bulging of a blood vessel in the brain and can be fatal if they burst.

Researchers at Lawrence Livermore created a living, bioprinted aneurysm so that researchers could operate on it.

A team led by engineers William “Rick” Hynes and Monica Moya 3D-printed blood vessels with human cerebral cells. Hynes performed a repair procedure on the printed aneurysm and inserted a catheter into the blood vessel before tightly packing platinum coils inside the aneurysm sac. The researchers introduced blood plasma into the aneurysm and observed the formation of a blood clot where the coils were located, cutting it off from fluid flow. The researchers also were able to observe the “post-op” healing process of the cells within the vessels.

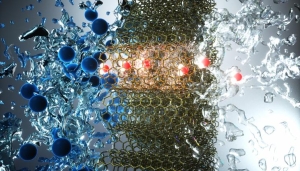

An artist’s view of small-diameter carbon nanotubes that pass through water molecules (red and white) and reject ions (blue). High permselectivity of small-diameter nanotubes can enable advanced water desalination technologies. Illustration concept: A. Noy, T. A. Pham, Y. Li, Z. Li, F. Aydin (LLNL). Illustration by Ella Maru Studios.

Big project comes in small packages

Membrane separations have become critical to human existence, with no better example than water purification. As water scarcity becomes more common and communities start running out of cheap available water, they need to supplement their supplies with desalinated water from seawater and brackish water sources.

Lawrence Livermore National Laboratory researchers have created carbon nanotube (CNT) pores that are so efficient at removing salt from water that they are comparable to commercial desalination membranes. These tiny pores are just 0.8 nanometers in diameter. In comparison, a human hair is 60,000 nanometers across.

Biological water channels, also known as aquaporins, provide a blueprint for the structures that could offer increased performance in desalination plants. Compared to current-day desalination technology, aquaporins have an extremely narrow inner pore that squeezes water down to a single-file configuration that enables extremely high water permeability, with transport rates exceeding 1 billion water molecules per second through each pore.