Are shapeshifting “soft machines” in our future? LLNL scientists advance light-responsive material

(Download Image)

(Download Image)

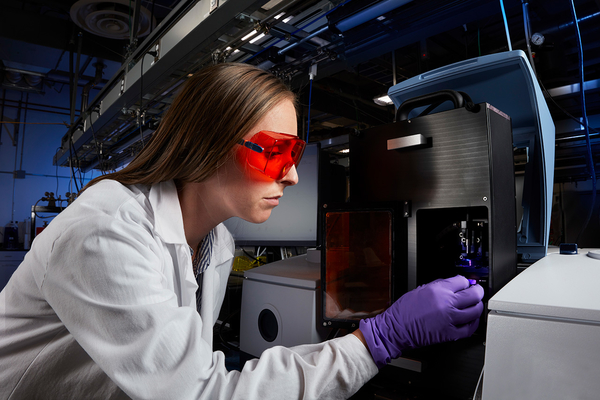

Lawrence Livermore National Laboratory researchers and their collaborators have created a new responsive material called a liquid crystal elastomer, made by incorporating liquid crystals into the molecular structure of a stretchable material. Adding gold nanorods to the material, the researchers created photo-responsive inks and 3D printed structures that could be made to bend, crawl and move when exposed to a laser light. (Photos courtesy: Michael Ford)

Researchers at Lawrence Livermore National Laboratory have furthered a new type of soft material that can change shape in response to light, a discovery that could advance “soft machines” for a variety of fields, from robotics to medicine.

The novel material, called a liquid crystal elastomer (LCE), is made by incorporating liquid crystals into the molecular structure of a stretchable material. Adding gold nanorods to the LCE material, scientists and engineers created photo-responsive inks and 3D printed structures that could be made to bend, crawl and move when exposed to a laser that causes localized heating in the material. The results were recently published online by Matter, and will be featured in the journal’s March print issue.

As described in the paper, the LLNL team, along with their collaborators from Harvard University, North Carolina State University and the University of Pennsylvania, used a direct ink writing printing technique to build a variety of light-responsive objects, including cylinders that could roll, asymmetric “crawlers” that could go forward and lattice structures that oscillated. By combining shape morphing with photoresponsivity, researchers said the new type of material could change the way people think about machines and materials.

“At LLNL, we’ve focused on developing static materials and architectures for some time,” said principal investigator Caitlyn Krikorian (Cook). “We’ve made these complex types of structures like hierarchical lattices, and we’ve even started exploring more responsive materials, like shape memory polymers, that have a one-time shape memory response. But the Lab really hadn't delved deep into creating architectures that can go from a 3D-to-3D type of shape change. This project is starting to show how architecture and these novel materials can have unique modes of actuation that we haven't researched before.”

Researchers said the new material could be used to create a “soft machine” — a type of machine made from these flexible LCE composite materials — capable of responding to external stimuli and even mimicking the movements and behaviors of living organisms. Soft robots made of the shape-morphing material could crawl, swim or fly, and explore environments that are too difficult or dangerous for humans to access, like caves or outer space. Soft machines could also be used in medical applications, such as implantable devices that can adapt to the body's movements, or prosthetic limbs that move like natural limbs, and other applications that aren’t possible with machines made from rigid materials, like metal or plastic.

“Rigid robots maybe wouldn’t be ideal for humans to interact with, so we need systems and materials that are more compliant,” said the paper’s lead author Michael Ford, who began working on responsive materials while a postdoc at Carnegie Mellon University. “You start with components that make up our robots, and one of those components is an actuator. That’s where these materials come in; they could potentially be an actuator. It reduces computational complexity; you're making a material that gets rid of onboard electronics and replacing them with a single material that can do all those things. That will allow you to put more computational complexity into another component or drive power to other sensors that you wouldn't have been able to do with traditional rigid materials.”

Researchers said the movement of the LCE material is driven primarily by a process known as photothermal actuation, which involves converting light energy into thermal energy resulting in a mechanical response from the material. Driven by the interaction between light, gold nanorods and the LCE matrix, the process enables the printed structures to exhibit dynamic and reversible movements in response to external stimuli.

“When you have this composite material — in this in case, these gold nanorods in these liquid-crystal elastomers — it has a photothermal effect,” Cook explained. “With [infrared] light, it creates a heating effect, which causes the aligned molecules to become misaligned. During that misalignment process, if there's uniform heating, you’ll have a global shape change. But in this case, we can have localized heat change, which is how you can get those localized regions of shape morphing to do things like locomotion.”

In the study, researchers used a computer vision system, involving cameras and a tracking software, to control the movement of a printed cylinder. The tracking system monitored the position of the rolling cylinder and continuously adjusted the position of the laser to raster the edge of the cylinder. This continuous tracking and adjustment allowed for the cylinder to maintain its rolling motion in a controlled manner.

By leveraging computer vision with the photothermal actuation of the cylinder, the researchers achieved a sophisticated level of manipulation of the soft machine's movement, showcasing the potential for advanced control systems in the field of soft robotics and soft machines. The team also showed that responsivity could be controlled so the soft machines could perform useful tasks, such as a moving cylinder carrying a wire.

“[Lead author Ford] did some awesome work in using computer vision to control the locomotion of the printed cylinder and using a rastering laser to force it to move,” said co-author Elaine Lee. “But once you start to get into much more complex motion — like using various rastering speeds and light intensities on a printed lattice, causing it to move in various different modes — those were actually outside of what our high performance computing (HPC) simulations were able to predict, because those codes are expecting a uniform heating or stimuli on that lattice. So, using computer vision and machine learning to learn the actuation speeds, and what doses of light can cause locomotion from that printed architecture, will push us a lot further in understanding how our materials will respond.”

Researchers said there are still some challenges that need to be overcome before the material can be used in practical applications. The team found that structures they created could flip over or exhibit other unpredictable motion, thereby making it difficult to design specific modes of motions. They said they will continue to work on models that can describe the complex motion to better design future machines and develop new materials and manufacturing techniques to create soft machines that are more durable, reliable and efficient for a variety of applications. New control systems and computer algorithms also could enable soft machines to move and interact with their environment in a more intelligent and autonomous way, they said.

Cook said the team is looking at incorporating responses to different types of stimuli, beyond thermal and light stimuli, into areas like humidity and energy absorption, and conditions that the material might experience in space. She added that the team is looking at starting a new Strategic Initiative at the Lab to focus on autonomous materials and “move the needle” towards sentient materials.

“We’re all thinking about ways to make materials more autonomous; sentient materials that can sense, respond, be programmed, learn, decide and communicate,” Cook said. “These liquid crystal elastomers are responsive materials — they’re able to sense a stimuli and respond, and will respond repeatedly every time — but it doesn't have a sense of memory or a way to learn the repeated stimuli and respond accordingly. It doesn't have a means to communicate yet, other than potentially being able to pair it with some type of mechanical computing. These are really the materials that we're striving towards, and this might be a five- to 10-year timespan of effort.”

Funding for the research came from the Laboratory Directed Research and Development project “Shape Changing of Responsive Elastomer Structures,” and a grant from the National Science Foundation. Other LLNL co-authors included Dominique Porcincula, Colin Loeb, Julie Mancini and Bryan Moran. External collaborators included Rodrigo Telles and Jennifer Lewis from Harvard; Yuchen Wang and Shu Yang from UPenn; and Mehedi Rizvi and Joseph Tracy of NC State.

Contact

Jeremy Thomas

Jeremy Thomas

[email protected]

(925) 422-5539

Related Links

Matter article3D-printed metallic materials

Shape memory polymers

Shape Changing of Responsive Elastomer Structures

Video on YouTube