Work resumes in support of stockpile modernization

(Download Image)

(Download Image)

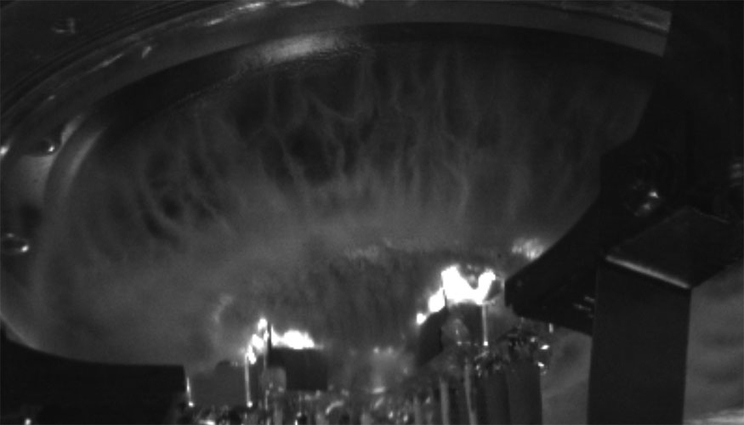

High-resolution image shows the impact of Del Mar coupon surface on the diagnostics probe assembly.

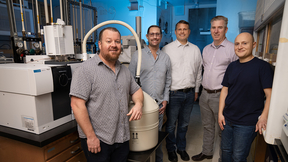

The effort to resume hands-on work in support of stockpile modernization programs reached a major milestone May 7 with the successful execution of a focused experiment at the High Explosives Applications Facility (HEAF) at Lawrence Livermore National Laboratory (LLNL). The experiment is the first using high explosives at the Laboratory since Alameda County issued a shelter-in-place order March 16 and the Laboratory went into “Reduced Mission Critical Operations” in response to the COVID-19 pandemic.

LLNL is the lead design agency for two stockpile modernization programs, the W87-1 Modification Program (W87-1 Mod) and W80-4 Life Extension Program (W80-4 LEP). These two programs were among those deemed as priorities by the National Nuclear Security Administration (NNSA) in the phased, deliberate resumption of work at the Laboratory.

The experiment, dubbed Del Mar, was set for March 17, just a day after the shelter-in-place was ordered. On April 28, the team was given the green light to get back to work on the experiment, after a thorough evaluation of the facility and new work controls to ensure worker safety during the experiment. Experiments similar to Del Mar were a regular occurrence before the pandemic; however, executing Del Mar proved to be anything but business as usual.

“It’s not your typical way of doing things,” said Fady Najjar, the LLNL physicist who designed the experiment. “We were unable to go on site or into HEAF to meet with the operations team. We couldn’t be in the control room to make sure we were getting the data. We couldn’t go in the tank to see the setup. You want to see the experiment before the shot is fired. You want to feel it when it goes off. All these things were missing for me. That gave me a lot of angst and concern.

“With that said, the operations team did an amazing job to make sure we stayed connected throughout the process,” Fady continued. “We had numerous video conferences to review pictures of the setup and talk through issues as they popped up. It was really a well-oiled machine. The team did an outstanding job.”

Del Mar was conducted in the largest steel firing tank vessel at HEAF, which can confine the detonation of up to 10kg of high explosives. Multiple diagnostics were trained on the explosion, all timed to capture key moments of the experiment, which was over in less than 100 microseconds. In the end, the experiment had 100 percent data return, which is an exceptional result even in the best of times.

“We have never operated like this before,” said JB McLeod, LLNL Integrated Experiment Team lead. “There’s a level of interaction that we’re accustomed to between the design and facility teams and that had to change for this experiment. All the setup and testing was completed while wearing extra protective gear and maintaining new distancing requirements. There were different conditions we had to think through and navigate to do this shot. It was a big team effort.”

Focused experiments like Del Mar and its predecessor Saturn Scythe provide key data and understanding that benefits programs like the W80-4 LEP and W87-1 Mod.

Since underground nuclear testing ended in 1992, the W87-1 Mod is the first modernization program to involve the complete re-manufacture of all system components. Researchers rely on a wide range of experiments as well as past nuclear test data to validate supercomputer simulations of how the individual components will perform and work together as a whole.

Adding to the complexity of the W87-1 is the fact that the warhead is being designed for a new delivery system, an intercontinental ballistic missile (ICBM) system currently under development by the U.S. Air Force called the Ground-Based Strategic Deterrent (GBSD). GBSD will replace the ‘70s-era Minuteman III ICBM and the W87-1 Mod will replace the 38-year-old W78 warhead.

The W87-1 Mod is in Phase 6.2 of the nuclear weapons lifecycle, where researchers study the feasibility of design options for the replacement warhead. The program is scheduled to enter Phase 6.2A in 2021, where researchers will develop a thorough cost study for the selected design options. In Phases 6.3 and 6.4, LLNL will complete the engineering design and work closely with NNSA production plants to ensure that the production process delivers parts that meet requirements. Phase 6.5 marks the first production run of the W87-1 Mod, which is scheduled for fiscal year 2030.

“A short pause can cause a much longer delay in the program,” said Juliana Hsu, W87-1 program manager. “This is a critical time to finish the design, and the pause certainly squeezes our timescale, which is a concern. However, the health and safety of the team was an even bigger concern for me. We needed to pause, and we’ve been very cautious and deliberate when taking steps to resume work like this. It really is a tough balance to reach. The nation is relying on us to deliver. At the same time, the W87-1 Mod team is relying on me to ensure that the work environment is safe. I wouldn’t want to continue work and cause people to get sick. When I ask the team to come back in, they’re trusting me. I take that responsibility seriously.

“This experiment is a big deal, considering the past couple months,” Hsu continued. “We’ve improvised, we’ve adapted and, with this Del Mar under our belt, I sense that we’re starting to overcome.”

Contact

Nolan O'Brien[email protected]

925-422-3399

Related Links

NNSATags

Global SecurityStrategic Deterrence

Featured Articles