LLNL scientists and engineers capture five awards for top industrial innovations

Lawrence Livermore National Laboratory researchers have garnered five awards for developing cutting-edge technologies with commercial potential.

Five teams of LLNL scientists and engineers have won awards from the trade journal R&D Magazine for developing advances among the top 100 industrial inventions worldwide for 2006. They worked with five universities, four industrial collaborators and another national laboratory.

This year’s R&D 100 awards, sometimes called the “Oscars of invention,” will be presented Oct. 18 during a black-tie dinner in the Grand Ballroom of Chicago’s Navy Pier.

“We are pleased by the Laboratory’s continued success in producing innovations that benefit the nation and U.S. industry,” said Cherry Murray, LLNL’s deputy director for Science and Technology. “These technologies highlight the Laboratory’s long-standing tradition of using multidisciplinary teams to solve important national problems.”

With this year’s awards, the Laboratory has captured a total of 118 such awards since 1978. Department of Energy (DOE) labs received 32 R&D 100 awards in this year’s judging.

“Once again, DOE’s labs are at the cutting edge of innovation with new technology developments to enhance America’s economic and national security,” U.S. Secretary of Energy Samuel Bodman said. “My heartiest congratulations to the DOE researchers and scientists that have won R&D Magazine’s prestigious awards this year.”

Protecting vision

Livermore researchers have helped develop a new instrument that could revolutionize retinal imaging, providing eye doctors with the capability to detect, diagnose and treat blinding retinal diseases more successfully.

Developed in conjunction with five universities and an industrial partner, the instrument — known as the Micro Electro Mechanical System (MEMS)-based Adaptive Optics Scanning Laser Ophthalmoscope (MAOSLO) — will enable clinicians to image and measure microscopic structures of the living eye, such as individual photoreceptors and ganglion cells.

Clinical trials, which have been under way for nearly a year, show that the instrument’s resolution and three-dimensional sectioning capabilities represent an important breakthrough in visualizing the retina.

The MAOSLO can measure and automatically correct aberrations in the eye in real-time; provide non-invasive, in vivo images of the retina at the cellular level; and enable optical sectioning of different cellular layers in the retina, among other tasks.

MAOSLO’s new capabilities are made possible by using the latest advances in adaptive optics and MEMS technology. This instrument uses the same adaptive optics principles employed in the world’s largest telescopes to provide clear images of distant astronomical objects.

The instrument’s core design was developed by LLNL researchers, along with researchers from the optometry schools at UC Berkeley and Indiana University, and the University of Rochester’s Center for Visual Science. Initial testing was done at the UC Davis Medical Center, and clinical operations are under way at the University of Southern California’s Doheny Eye Institute. Boston Micromachines Corp. developed and supplied the key MEMS technology for the MAOSLO.

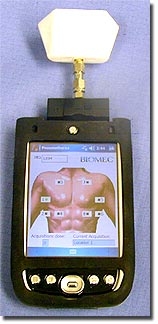

A Pneumothorax Detector

LLNL scientists engineers have developed a new medical diagnostic device to detect pneumothorax, a medical condition caused by having air trapped in the space between the wall of the chest cavity and the lung.

The R&D 100 award was shared by the Laboratory and Cleveland, Ohio-based Electrosonics Medical Inc., which licensed the technology and has advanced it through final commercial development and clinical trials.

Known as the “Noninvasive Pneumothorax Detector,” the handheld instrument uses the ultra-wideband radar technology pioneered in the 1990’s by LLNL researchers who had worked on the Nova laser.

The medical condition of pneumothorax often results in reduced lung capacity or a collapsed lung. If it is not properly diagnosed and promptly treated, pneumothorax can cause death within minutes.

Current methods to definitively diagnose pneumothorax involve the use of chest X-rays or computed tomography (CT) scans. In some cases, however, there may not be sufficient time to use X-rays or CT scans, or the patient may be in a remote location where these methods aren’t available.

Medical response teams in the field use the less conclusive method of looking for respiratory distress, listening for unusual sounds in the lungs and feeling for broken ribs.

A portable, light-weight, battery operated device, the Noninvasive Pneumothorax Detector can accurately diagnose pnuemothorax in real time, and can be used in a hospital setting and in the field.

An optics breakthrough

LLNL laser scientists have developed continuous phase plate optics that are an important breakthrough for the Laboratory’s National Ignition Facility and allow the laser’s 192 beams to be optimally coupled to its targets.

These optics, developed in conjunction with Zygo Corp. of Middlefield, Conn. and QED Technologies of Rochester, N.Y., are a vital part of the optics chain for kilojoule- and megajoule-class laser systems like NIF, France’s Megajoule Laser, and the Omega laser at the University of Rochester’s Laboratory for Laser Energetics.

Composed of fused silica, continuous phase plate optics are about 17 inches high and 17 inches wide, and about 3/8 of an inch thick. The surface of the optics is imprinted with a computer designed topographical structure that resembles hills and valleys. The process is designed to polish this structure into the optic surface to within 30 nanometers — or about one-millionth of an inch — of design specifications.

These large-aperture ultra-precision diffractive optics make it possible to adjust and fine-tune a laser beam to a prescribed size and shape while maintaining the coherent properties of the laser light.

“These optics allow the light coupling to an inertial confinement fusion target to be manipulated in a manner that results in uniform heating and generation of X-rays in the hohlraum surrounding the fuel, thereby providing the necessary pressures and temperatures to initiate fusion,” said LLNL chemist Joe Menapace.

Continuous phase plate optics are produced using an advanced optical finishing process — called magnetorheological finishing — that combines deterministic polishing techniques, interferometry, precision equipment and computer control.

Detecting nuclear materials

For the third year in a row, Livermore scientists and engineers have won an R&D 100 award for developing an advanced radiation detection system — this time, for 2006, for the Large Area Imager.

About the size of two large desks, and often carried in a trailer, the Large Area Imager provides several important advances for detecting and interdicting illegal nuclear materials. The instrument was developed in collaboration with Oak Ridge National Laboratory and the UC Berkeley Space Sciences Laboratory.

The Large Area Imager allows investigators to seek and find radiation sources by using a moving vehicular platform with total insensitivity to variations in an area’s radiation field, which can include soil, buildings or even a person who has recently had tests with certain medical isotopes.

Naturally occurring fluctuations limit the detection ranges of current radiation detection instruments to about 10 meters. In comparison, the Large Area Imager simultaneously searches a swath 100 meters wide (50 meters on either side of the unit).

Another advantage of the Large Area Imager is that it can be used in searches at speeds up to 25 miles per hour, while many radiation detection systems require the users to walk.

Additionally, the new instrument displays the location of a radiation source in real time — to within five meters on overhead, geospatial imagery — and also shows the field of view and areas that have been swept.

In 2005, LLNL researchers won an R&D 100 award for the Adaptable Radiation Area Monitor, which can detect small quantities of radiation moving at either slow speeds or as fast as 60 miles per hour. In 2006, Lab scientists won another R&D 100 award for a high-precision radiation detector called UltraSpec that operates at very low temperatures and also can find small amounts of nuclear materials.

hypre -Active software speeds supercomputing

Laboratory computer scientists have developed a software library called hypre that allows researchers to use supercomputers such as BlueGene/L and ASC Purple more effectively to conduct larger, more detailed simulations faster than ever before.

The ability to run large detailed simulations in less time is critical to stockpile stewardship and other DOE/NNSA national security programs. The use of massively parallel machines with as many as tens of thousands of processors that allow the detailed simulation of large scale physical phenomena has become an essential part of scientific research and discovery.

Physical systems are described by complicated sets of mathematical equations that must be solved on computers to simulate reality. Large systems of linear equations are ubiquitous in scientific and engineering simulation codes, and solving these systems of equations is often the most time-consuming function of a code. Consequently, robust and efficient algorithms to solve systems of linear equations are in great demand.

Hypre , which stands for “high performance preconditioners,” is a software library unique in its ability to provide solution algorithms that are effective on a wide variety of problems, easily accessible using multiple user interfaces, and effectively exploit the full computational power of today’s high performance computers.

The challenge traditionally for parallel linear solver algorithms has been scalability. An application code is scalable if it can use additional computational resources effectively. If the size of the problem and the number of processors are increased proportionally, the goal is to keep the computing time approximately the same. In practice however, as simulations grow to be more detailed and realistic, computing time may increase dramatically even when more processors are added to solve the problem.

Hypre provides linear solver algorithms that are developed specifically to be scalable on large numbers of processors. As a result, some simulation times may be reduced by orders of magnitude — as much as a factor of 30. Simulations that previously took days can now be run in hours or less.

Founded in 1952, Lawrence Livermore National Laboratory has a mission to ensure national security and to apply science and technology to the important issues of our time. Lawrence Livermore National Laboratory is managed by the University of California for the U.S. Department of Energy’s National Nuclear Security Administration.

Contact

Steve Wampler[email protected]

925-423-3107

Related Links

R&D 100 AwardsAdaptive Optics Provide A Clearer View

Doheny Eye Institute

Pneumothorax Detector White Paper

Electrosonics Medical, Inc.

National Ignition Facility

Zygo Corp.

QED Technologies

Imagers Provide Eyes To See Gamma Rays

Radiation Detection on the Front Lines

Large Area Imager: LLNL Industrial Partnerships & Commercialization

Hypre: Scalable Linear Solvers project