Microgravity experiments reveal metallurgical phenomena

(Download Image)

(Download Image)

(left) An optical image of the solid–liquid interface during the growth of a transparent solid alloy. (right) Four phase-field simulations of the observed phenomena. Due to misoriented grains, cells can invade the neighboring grain, leading to highly convoluted grain boundary shapes (cyan). During the invasion process, a solitary cell can emerge (marked in yellow).

In solidification processing, such as casting, welding, or additive manufacturing, cellular or dendritic patterns develop during the growth of a solid crystal from the liquid phase. In metallurgy, each similarly patterned region is referred to as a grain—which must be controlled during processing as grains affect structural performance. Additionally, the grain texture—the resulting macroscopic distribution of grain orientations and grain boundaries (GBs)—has a key influence on material strength.

To better understand how grains and GBs form and interact with neighboring grains, postdoctoral researcher Younggil Song and international collaborators performed phase-field simulations in coordination with reduced gravity experiments onboard the International Space Station (ISS)—the microgravity conditions on the ISS eliminated flow associated with buoyancy.

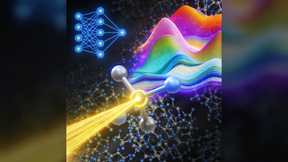

For the experiments, the use of a transparent solid alloy enabled characterization of the cell and grain structure, revealing that individual cells from one grain can unexpectedly invade a nearby grain of different misorientation, either as a solitary cell or rows of cells. This invasion process causes grains to interpenetrate each other, and thus grain boundaries adopt highly convoluted shapes. Additionally, it was found that leading invader cells can detach from the original grain and survive for a long time in the neighbor grain as solitary cells.

These observations, published in Nature Communications, were reproduced using the fully 3D phase-field simulation code that Song developed. With this code, researchers were able to model the observed in situ phenomena for the first time. Computational Materials Science Group Leader Robert Rudd says, “This knowledge and the ability to model these processes will open new possibilities for alloy design.”

[Y. Song, F. L. Mota, D. Tourret, K. Ji, B. Billia, R. Trivedi, N. Bergeon, A. Karma, Cell invasion during competitive growth of polycrystalline solidification patterns, Nature Communications (2023), DOI: 10.1038/s41467-023-37458-0.]

Tags

Advanced Materials and ManufacturingMaterials Science

Physical and Life Sciences

Featured Articles