Turning unwanted carbon dioxide into electricity

SAN FRANCISCO - Researchers are developing a new kind of geothermal power plant that will lock away unwanted carbon dioxide (CO 2 ) underground and use it as a tool to boost electric power generation by at least 10 times compared to conventional geothermal power.

The technology for this design already exists in different industries, and the researchers, led by Tom Buscheck, earth scientist from Lawrence Livermore National Laboratory, are hopeful that their new approach to the technology will expand the use of geothermal energy in the U.S. far beyond the small handful of states that can take advantage of it now. Heat Mining Company, LLC, a startup spun off from the University of Minnesota, expects to have an operational project based on an earlier form of this new approach in 2016.

At the American Geophysical Union meeting on Friday, Dec. 13, Buscheck and his colleagues from The Ohio State University, the University of Minnesota and Lawrence Livermore, will debut an expanded version of the design and explain the role that this new approach to geothermal energy production and grid-scale energy storage can have in addressing climate change.

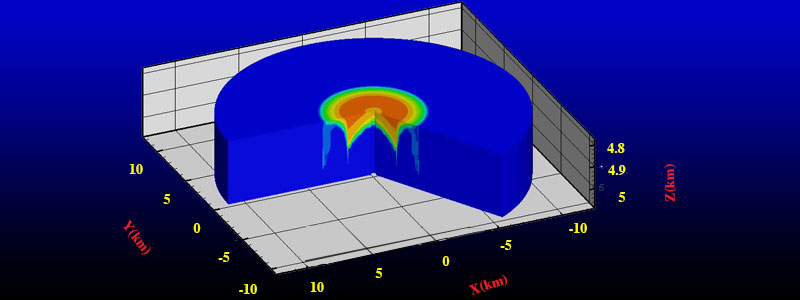

The new power plant design resembles a cross between a geothermal plant and the Large Hadron Collider: it features a network of subsurface concentric rings of horizontal wells inside which CO 2, nitrogen and water circulate to draw heat from deep below ground up to the surface, where it can be used to turn turbines and generate electricity.

"This well arrangement encircles the injected fluids with a subsurface hydraulic dam, functioning much like a hydroelectric dam. The intent is to recover the maximum energy benefit from fluid injection operations, a major improvement over conventional geothermal power systems," Buscheck noted.

The design contrasts with conventional geothermal plants in a number of important ways, explained study co-principal investigator Jeffrey Bielicki, assistant professor of energy policy in the Department of Civil, Environmental and Geodetic Engineering at The Ohio State University.

"Typical geothermal power plants tap into hot water that is deep underground,pull the heat off the hot water, use that heatto generate electricity and then return the cooler water back to the deep subsurface. Here the water is partly replaced with CO 2 and/or another fluid," he said.

"Tt that there are benefits to using CO 2, because it mines heat from the subsurface more efficiently than water," he continued."This combined approach (originally developed by Martin Saar at the University of Minnesota) can be at least twice as efficient as conventional geothermal approaches, and expand the reach of geothermal energy in the United States to include most states west of the Mississippi River."

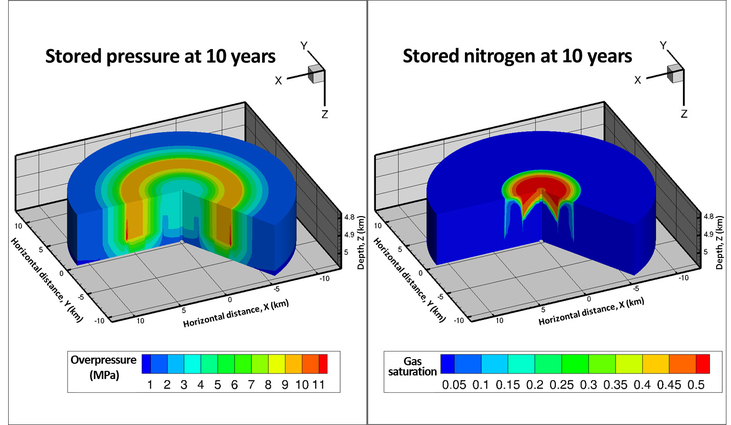

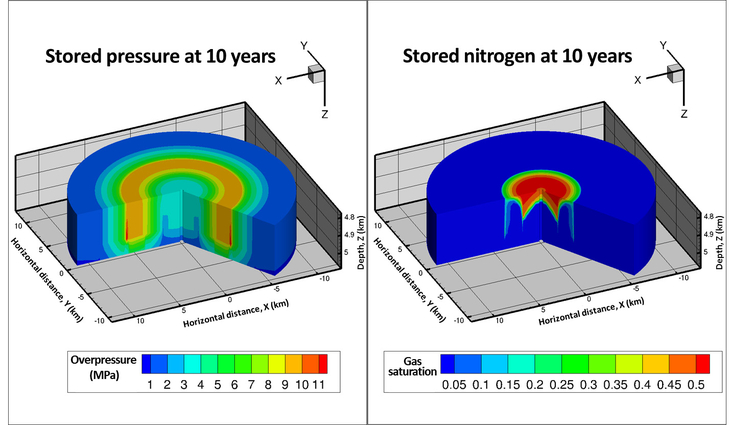

The research team used computer simulations to design the system. In the simulations, a system of four concentric rings of horizontal wells about three miles below ground, with the outer ring being a little more than 10 miles in diameter, produced as much as a half a gigawatt of electrical power - an amount comparable to a medium-sized coal-fired power plant, and more than 10 times bigger than the 38 megawatts produced by the average geothermal plant in the U.S.

The simulations also revealed that a plant of this design might sequester as much as 15 million tons of CO 2 per year, which is roughly equivalent to the amount produced by three medium-sized coal-fired power plants in that time.

"One of our key objectives when we began developing the CO 2 plume geothermal technology was to find a way to help make CO 2 storage cost effective while expanding the use of geothermal energy," said Jimmy Randolph, postdoctoral researcher in the Department of Earth Sciences at the University of Minnesota.

During the past year, Buscheck added another gas - nitrogen - to the mix, resulting in a design that he and his colleagues believe will enable highly efficient energy storage at an unprecedented magnitude (at least hundreds of gigawatt hours) and unprecedented duration (days to months), provide operational flexibility, and lower the cost of renewable power generation.

"Nitrogen has several advantages," Buscheck explained. "It can be separated from air at lower cost than captured CO 2, it's plentiful, it's not corrosive and will not react with the geologic formation in which it is being injected. And because nitrogen is readily available, it can be injected selectively. Thus, much of the energy required to drive the hot fluids out of the deep subsurface to surface power plants can be shifted in time to coincide with minimum power demand or when there is a surplus of renewable power on the electricity grid.

"Because we are storing energy in the form of pressurized fluids, we can further improve on this concept by selectively producing hot fluids when power demand is high, as well as reduce or stop that production when power demand is low. What makes this concept transformational is that we can deliver renewable energy to customers when it is needed, rather than when the wind happens to be blowing, or when spring thaw causes the greatest runoff."

The technology could possibly be used to expand the use of geothermal energy around the country. Right now, most geothermal power plants are in California and Nevada, where an especially strong geothermal gradient heats water underground. But the new design is so much more efficient at extracting heat that even smaller-scale "hotspots" throughout the western U.S. could generate power. (The eastern U.S. is mostly devoid of even small hotspots, so geothermal power would still be limited to a few particularly active areas such as West Virginia, Bielicki said.)

Another caveat: the geothermal plant would probably have to be connected to a large CO 2 source, such as a coal-fired power plant, which was scrubbing the CO 2 from its own emissions. That connection would likely be made by pipeline. Buscheck added, however, that a pilot plant based on this design could initially be powered solely by nitrogen injection, in order to prove the economic viability of using CO 2. The study also showed that this design can work effectively with or without CO 2, broadening where this approach could be deployed. The research team is currently working on more detailed computer model simulations and economic analyses for specific geologic settings in the U.S.

Co-authors on the presentation included Mingjie Chen, Yue Hao, Yunwei Sun, all of Lawrence Livermore. Work at the University of Minnesota and The Ohio State University is funded by the National Science Foundation, while work at Lawrence Livermore National Laboratory is funded by the U.S. Department of Energy's Office of Energy Efficiency and Renewable Energy.

Contact

Anne M. Stark

Anne M. Stark

[email protected]

(925) 422-9799

Related Links

S gas animationdP animation

DOE Office of Energy Efficiency & Renewable Energy

The Ohio State University

University of Minnesota

Related Files

DownloadTags

Physical and Life SciencesFeatured Articles