Sandia and LLNL team successfully execute second W80-4 abnormal thermal environment test

Lawrence Livermore National Laboratory (LLNL) and Sandia National Laboratories (Sandia) recently successfully executed the second joint abnormal thermal environment (ATE-2) test for the W80-4 Life Extension Program (LEP). Carried out at Sandia’s Cross Wind Test Facility in New Mexico, ATE-2 was a fast-heat, fully engulfing system-level fuel fire test, the first for LLNL in more than three decades.

The test is a major milestone for nuclear safety certification of the W80-4 and provides valuable data to validate the team’s computational models.

“These system-level tests are essential for providing evidence that nuclear safety requirements are met and provide the primary basis for nuclear safety certification,” said Charlie Hamann, the W80-4 Systems Engineering and Integration (SE&I) group leader in the Defense Engineering Technologies Division (DTED) at LLNL.

“The data that we’ve obtained allows us to show that the warhead will respond in a safe and predictable manner in some of the most extreme credible accident scenarios that could occur when the weapon is in the stockpile,” said Erik Merilo, Abnormal Environment Assessment lead for the W80-4 and a group leader for Engineering Design and Test (ED&T) in DTED.

"The test was executed nearly flawlessly to plan with all test objectives met, demonstrating the high degree of preparation from the joint test team and the Sandia test facility,” said Terry Johnson, distinguished member of technical staff and Thermal Qualification Lead for the W80-4 at Sandia.

Toward certification

One of the core missions for LLNL and Sandia is to ensure that the nation’s nuclear stockpile is safe, secure and reliable. As part of this effort, weapon modernization programs like the W80-4 need to go through a nuclear safety certification process, and the team must demonstrate that the new warhead will meet safety requirements in a wide range of accident scenarios. To do this, they use a combination of testing and computational models.

“It’s not possible to perform tests for every credible accident scenario, so we select specific environments that stress the safety theme and conduct tests in those environments to characterize how the weapon responds,” explained Merilo. “We use the data from these tests to calibrate our computational models and then use the models to evaluate scenarios that we are not testing.”

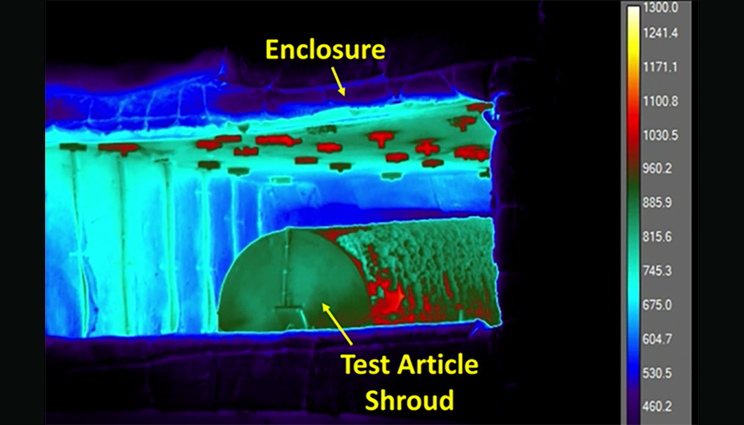

W80-4 test article on ceramic test stand in the test enclosure.The results from ATE-2, along with ATE-1 — an intermediate heating rate test carried out last summer in the Contained Firing Facility at Site 300 — will allow the team to understand how the weapon will respond across a range of abnormal thermal environments. Together, the tests act as “tentpoles” — two extreme scenarios between which lie most other areas of concern.

“The suite of analyses used to assess a broad range of scenarios can be thought of as the canvas, and the system-level tests are the tentpoles that hold up the canvas,” Hamann said. “Moving between these tentpoles via computational modeling allows us to evaluate untested scenarios.”

A team effort

ATE-2’s success was the culmination of nearly two years of effort across both LLNL and Sandia. The backbone was Sandia and LLNL’s abnormal environments working group, which has been meeting bi-weekly since 2018. The team, consisting of nuclear safety, qualification, testing and modeling/simulations representatives from both labs, worked closely together on every part of the test planning process, from test unit design and instrumentation to post-test recovery and forensics.

In LLNL’s Engineering directorate, DTED engineers and technicians worked together to design the LLNL ATE-2 test article and integrate key instrumentation and diagnostics. The Materials Engineering Division’s service centers and shops played a vital role in fabricating and inspecting critical hardware needed for the system level test. Analysts from the Computational Engineering Division ran numerous simulations to help refine the design of the test article and predict the results of the test.

“Performing a test of this complexity is a true team effort,” said Daniel Dunning, the LLNL W80-4 Nuclear Safety lead. “Team members with a wide range of skills worked together effectively to accomplish many challenging tasks, and that is really what has led to the team’s success.”

During the test, the team was able to successfully capture all tier one (must-have) and tier two (strongly desired) data — an impressive feat, given the fragile nature of some of the instrumentation and the harsh environment.

“This is a true testament to the skill and dedication that went into design, fabrication and assembly of this test article, as well as efforts that were performed by the Sandia team who setup the test at the facility,” Merilo wrote in an email the night of the test. “I would like to thank everyone for their contributions to this effort which allowed us to complete another successful test.”

The team is planning two more ATE tests to study additional scenarios and further validate their models. Each of these steps moves the program closer to certification while laying the groundwork for testing both current and future weapons systems. ATE-2 was performed as part of the W80-4 program, but the techniques and technologies that have been implemented will inform certification efforts for future modernization programs and can be used to assess systems in the stockpile today.

-Noah Pflueger-Peters

Contact

Jeremy Thomas

Jeremy Thomas

[email protected]

(925) 422-5539

Related Links

Sandia National LaboratoryTags

DefenseStrategic Deterrence

Featured Articles