Newly developed tunable, green detergents could be 'made-to-order' for industry

(Download Image)

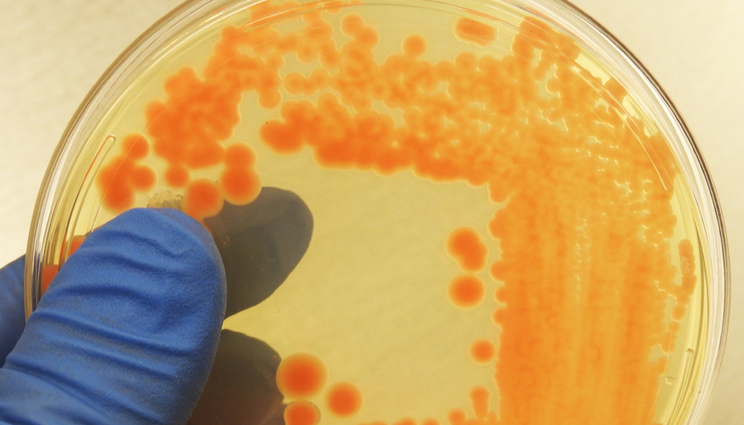

Rhodotorula yeast produces the newly LLNL developed biosurfactant. Rhodotorula is known as “red yeast” because of the carotenoid pigments they also synthesize; these are the same compounds that give carrots an orange-red color (beta-carotene), as well as the color of flamingo feathers (the flamingo diet is rich in carotenoids).

(Download Image)

Rhodotorula yeast produces the newly LLNL developed biosurfactant. Rhodotorula is known as “red yeast” because of the carotenoid pigments they also synthesize; these are the same compounds that give carrots an orange-red color (beta-carotene), as well as the color of flamingo feathers (the flamingo diet is rich in carotenoids).

That mascara that your colleague is wearing may contain components from a microorganism.

Detergents, also known as surfactants, are used extensively in the cosmetics, oil, food, agriculture, healthcare and pharmaceutical industries. Their sales are projected to reach $42 billion by 2020.

The majority of surfactants are petrochemicals, i.e. are synthesized from petroleum compounds. They often have a negative impact on the environment and increase the nation’s dependence on foreign and domestic oil. Therefore, the demand for biosurfactants (surfactants produced from a microorganism) is on the rise, especially since they only serve niche markets in Japan, Europe and the U.S.

But Lawrence Livermore National Laboratory (LLNL) scientists are studying a new "tunable" biosurfactant that is environmentally-friendly and can have broad industrial utility. It is produced by the red yeast Rhodotorula and is composed of a linear carbohydrate connected to a fatty acid.

"The primary challenge is that microorganisms produce biosurfactants as a complex mixture of closely-related surfactants, not a pure, single type of compound" said Matt Lyman, LLNL biologist and lead author of the paper appearing in PLOS ONE. "If we can harness the surfactant diversity that mother nature is showing us, but provide it in a pure form that is 'tunable' for the industry need, then it becomes a powerful technology, and beyond what currently exists for commercial biosurfactants."

The tunability aspect of surfactants is known in the industry as "hydrophilic-lipophilic balance" (HLB). The HLB is a scale from 0-20, and determines whether a surfactant is more "water-loving" or more "oil-loving"; this HLB score largely determines what surfactants are used in shampoos, toothpaste, oil extraction, laundry detergents, pesticides, paints and other applications.

"Existing biosurfactant mixtures only cover a small range of the HLB scale, thereby limiting their utility in the detergent market," said Bonnee Rubinfeld, a LLNL biologist and co-author on the study.

The aim of the LLNL team is to use Rhodotorula as a "microbial factory" to produce a base surfactant compound at minimal cost. The team will then perform routine chemical modifications to enable it to slide up and down the HLB scale for a wide range of industrial needs. Such a system would provide a "made-to-order" biosurfactant, with a specific hydrophilic-lipophilic balance most useful to the customer and their application.

The research appears in the Jan. 2 edition of PLOS ONE, and was performed as an internal collaboration between the LLNL Biosciences and Biotechnology Division (Brian Souza, Larry Dugan, Rubinfeld and Lyman) and the LLNL Forensic Science Center (Roald Leif, Heather Mulcahy, and Carlos Valdez).

Contact

Anne M. Stark

Anne M. Stark

[email protected]

(925) 422-9799

Related Links

LLNL Biosciences and Biotechnology DivisionLLNL Forensic Science Center

Tags

Bioscience and BioengineeringBiosecurity and Bioforensics Group

Physical and Life Sciences

Featured Articles