Mechanical response without heat or electricity

(Download Image)

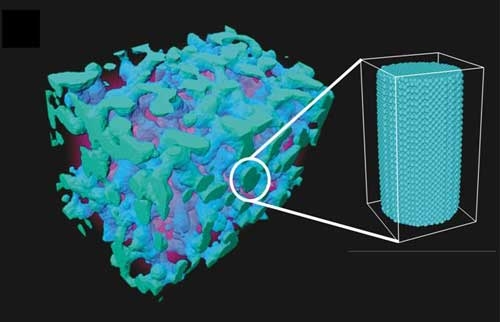

A molecular dynamics simulation of nanoporus gold and a 100-strand of gold nanowire resembling the ligaments of nanoporous gold.

(Download Image)

A molecular dynamics simulation of nanoporus gold and a 100-strand of gold nanowire resembling the ligaments of nanoporous gold.

Actuators may no longer need heat or electricity to operate if a new process goes into production.

Researchers at the Laboratory in collaboration with German colleagues have found a new way to directly convert chemical energy into a mechanical response without generating heat or electricity first.

The team led by Juergen Biener from LLNL’s Nanoscale Synthesis and Characterization Laboratory took a sample of nanoporous gold and alternately exposed it to ozone and carbon monoxide. By using the oxidation of carbon monoxide by ozone as a driver, the team achieved reversible macroscopic strain amplitudes of up to 0.5 percent.

And while actuation in biological systems is exclusively powered by chemical energy, this is the first time a man-made actuator technology uses nature’s concept. This new process could be applied to building high-sensitivity gas sensors.

The experiment is based on surface-chemistry-induced changes of the surface stress at a metal gas interface, which in turn drive the sample to contract and expand.

"Like nature’s muscles, our actuator directly converts chemical energy into a mechanical response without generating heat or electricity first," Biener said. "This discovery opens the door to a new generation of chemical driven sensor and actuation devices."

The team selected nanoporous gold for a number of reasons including its remarkable catalytic properties, its open cell foam morphology, which allows for mass transport, and its ability to sustain high stresses.

The research showed that ozone exposure leads to oxygen absorption which triggers a sample contraction by modifying the surface stress. Exposure to carbon monoxide then restores the original sample dimensions by removing the absorbed oxygen.

Through molecular dynamics simulations, the team was able to independently test the effect of surface stress on the equilibrium shape of realistic models of nanoporous gold and its structural building blocks.

"These simulations allowed us to understand the stress-strain response of nanoporous gold," Biener said.

Other researchers involved in this study are Arne Wittstock, Luis Zepeda-Ruiz, Monika Biener, Alex Hamza from LLNL, as well as Professor Baeumer’s group from the Institut für Angewandte and Physikalische Chemie of University of Bremen and Professor Weissmueller’s group from the Institut für Nanotechnologie of the Forschungszentrum Karlsruhe, both in Germany.

The research appeared in the Nov. 30 issue of the journal, Nature Materials .