LLNL researchers turn to microbe beads to increase U.S. supply of rare earth metals

(Download Image)

(Download Image)

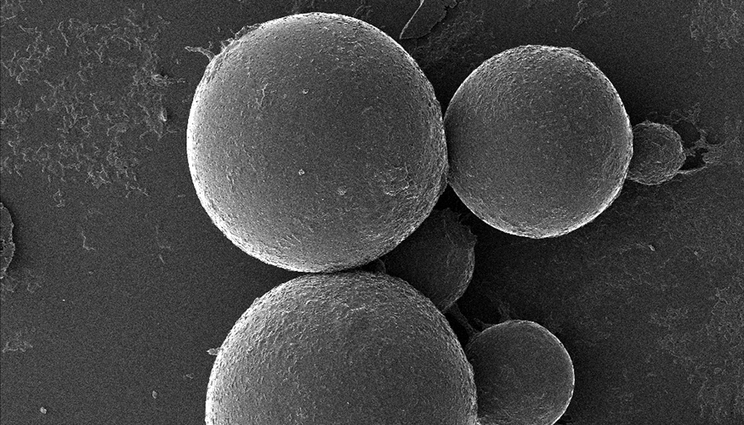

Helium ion microscopy images of microbe capsules at different magnification. At high magnification, encapsulated microbes are visible on the surface. The average bead size is 59 micrometers.

To help increase the U.S. supply of rare earth elements, a Critical Materials Institute team led by Lawrence Livermore National Laboratory (LLNL) is using microbe beads to recover rare earth elements from consumer electronic waste.

The team developed a scalable biosorbent material – a microbe-embedded polymer – by combining material science with microbiology. The research appears in the journal Environmental Science and Technology.

Rare earth elements (REEs) like neodymium and dysprosium are essential for technologies such as solar and wind energy, advanced vehicles and modern electronics like smartphones.

The new method could be used to recover REE’s from end of life products that use neodymium (NdFeB) magnets. These permanent rare-earth magnets are commonly used in wind turbines, hybrid and electric vehicles, household electrical appliances, computer hard disk drives and small consumer electronic devices, such as cell phones. The magnet has different life cycles depending on the application, from as short as 2-3 years for cell phones to 20-30 years in wind turbines.

“Recycling off REEs in this type of magnet from the end of life products will play an important and complementary role in the total supply of REEs in the future,” said Yongqin Jiao, LLNL bioscientist and co-lead author of the paper.

REEs are essential for American competitiveness in the clean energy industry because they are used in many devices important to a high-tech economy and national security.

Production of REEs and recycling of REE-containing products at end-of-life are currently limited domestically. The Livermore team is hoping to change that by creating a biosorption REE extraction method that uses less energy and is environmentally sustainable.

REEs comprise 17 elements in the periodic table -- scandium, yttrium and the 15 lanthanides. Despite their name, the rare earths (except for promethium) are not all that rare but are actually found in relatively high concentrations across the globe. However, because of their geochemical properties, they seldom occur in easily exploitable deposits. REEs occur together and require extensive chemical processing (traditionally) to isolate the individual REEs.

In the new research, the LLNL team engineered an E. coli biosorbent encapsulated in a permeable polyethylene glycol diacrylate hydrogel. The resulting microbe beads were able to selectively extract REEs from an industrially relevant electronic waste feedstock leachate. In addition, the microbeads are reusable, with adsorption capacity that remains unchanged after nine consecutive adsorption/desorption cycles tested so far.

“Our results demonstrate a generalizable biomass immobilization platform for continuous flow metal purification,” said LLNL bioscientist Dan Park, co-lead author of the paper. “This technique has important implications for industrial rare earth recovery using microbial biomass.”

Microbe-based adsorptive materials offer advantages for solid-phase REE extraction, with a strong potential for environmentally sustainable economic development.

“Microorganisms synthesize and display high-density surface-accessible functional groups as they grow and multiply, facilitating high-capacity REE adsorption without complicated and costly chemical synthesis steps,” Park said.

Microorganisms exhibit a general adsorption preference for REEs over most non-REE metal ions, and the surface-adsorbed REEs can be readily recovered through desorption, enabling efficient REE recovery and recycling of biomass.

The work is part of the Critical Materials Institute (CMI), a Department of Energy (DOE) Innovation Hub led by the DOE’s Ames Laboratory and supported by DOE's Office of Energy Efficiency and Renewable Energy's Advanced Manufacturing Office. CMI seeks ways to eliminate and reduce reliance on rare-earth metals and other materials critical to the success of clean energy technologies.

Besides the CMI scientists, the team also includes researchers from Idaho National Lab, University of California Berkeley and the Environmental Molecular Science Laboratory, a DOE Office of Science User Facility sponsored by the Office of Biological and Environmental Research, located at Pacific Northwest National Laboratory.

Contact

Anne M. Stark

Anne M. Stark

[email protected]

(925) 422-9799

Related Links

Environmental Science and TechnologyCritical Materials Institute

DOE Advance Manufacturing Office

Tags

Laboratory for Energy Applications for the FuturePhysical and Life Sciences

Featured Articles