LLNL researchers chart progress in architected materials that respond to external stimuli

(Download Image)

(Download Image)

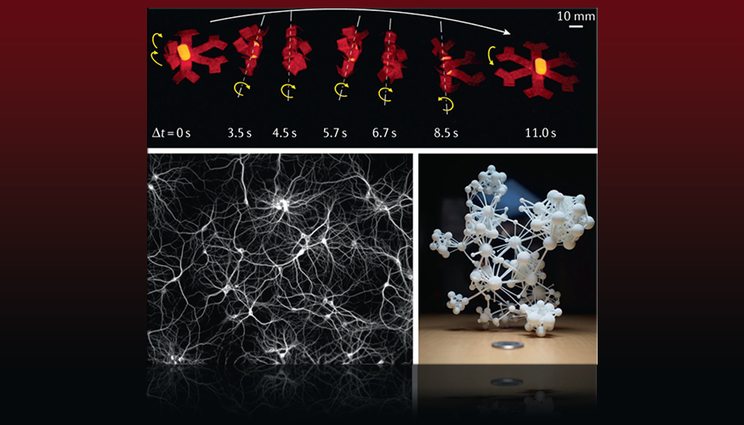

In paper published by Nature Reviews Materials, Lawrence Livermore National Laboratory researchers provide an overview of the progress made in responsive architected materials that can morph into a particular shape and exhibit new properties when exposed to heat, magnetic or electrical forces, chemical or electrochemical reactions and mechanical deformations.

Recent advances in pre-programmed architected materials could enable new functions that can evolve in response to their environments or external stimuli, according to Lawrence Livermore National Laboratory (LLNL) researchers.

In a paper published by Nature Reviews Materials, LLNL researchers provide an overview of the progress made in responsive architected materials that can morph into a particular shape and exhibit new properties when exposed to heat, magnetic or electrical forces, chemical or electrochemical reactions and mechanical deformations. The authors also explain the programming and transformation mechanisms of each approach and examine potential applications, including implantable medical devices, robotics and chemical or mechanical sensors. The journal will feature the paper on the cover of an upcoming print edition.

“Additive manufacturing has made it possible to create architected materials that have enhanced properties and novel functionality compared with the constituent materials due to their carefully designed internal and exterior structures,” said LLNL staff scientist and lead author Xiaoxing Xia. “These responsive architected materials are not stagnant after fabrication; they can evolve in space and time following a programmed trajectory and can respond to various forms of stimuli — be it mechanical, thermal, electromagnetic or chemical — and transform their shape, change properties or navigate autonomously.”

Assessing the current state of responsive architected materials, Xia and team compare responsive materials to dynamic phenomena found in classical materials, such as phase transformation and topological insulators, and describe them in the framework of computation and machine learning. Architected materials can not only conduct pre-programmed mechanical logic, but can also be trained and optimized by machine learning.

Deep neural networks are “potentially transforming” for designing materials with superior mechanical or electromagnetic responses, researchers said. For example, deep-learning algorithms could train on images of geometries and use them to generate novel structures with optimized performance, or design architected materials that can be 3D-printed and act as physical cores to perform inference tasks — such as hand-written number or vowel voice recognition — in real-time in response to sound or light, they concluded.

In the future, responsive architected materials could find their way into implantable medical devices, as vehicles for drug delivery, in “cloaking” technologies or autonomous robots, or be used to store or reveal sensitive information on demand, researchers said. They speculate that such materials could one day evolve to learn from past or current experiences, much like the human brain.

“Architected materials are becoming more and more intelligent, and in the future, they can be neuromorphic — meaning they can emulate the structure and function of the brain,” Xia said. “Here, we’re asking the question, ‘What if they could become sentient by developing preference for certain stimuli over others, which is analogous to feeling happiness or pain?’ They could be a model system for studying the brain.”

Julia R. Greer, a professor and materials scientist at the California Institute of Technology, was one of the co-authors of the paper. She said she envisions a future where nanoscale architected materials replace conventional materials in many areas of daily life and could someday even reach some level of sentience.

“To realize this vision of architected materials being ubiquitous in society — not just used in science and engineering — we will need new, more efficient and accurate computational models that can capture the mechanics and physics of additive manufacturing at an affordable price,” Greer said. “Knowing there are many talented people working on these problems, I look forward to the day when we can create architected materials and devices imbued with the ability to make decisions on their own."

LLNL Materials Engineering Division leader Chris Spadaccini also co-authored the article. The authors acknowledged Judah Goldwasser, a former Defense Advanced Research Projects Agency program manager and renowned materials scientist who supported pioneering efforts in creating architected materials at LLNL and the California Institute of Technology. Goldwasser died in 2020.

Contact

Jeremy Thomas

Jeremy Thomas

[email protected]

(925) 422-5539

Related Links

"Researchers look to computing's past to unlock 3D-printed mechanical logic gates for the future""Lab develops metamaterials that change mechanical properties under magnetic fields"

"Going beyond 3D printing to add a new dimension for additive manufacturing"

Tags

HPC, Simulation, and Data ScienceComputing

Engineering

Science

Featured Articles