LLNL researchers capture four awards for industrial innovation

LIVERMORE, Calif. — Laboratory researchers have garnered four awards for developing advanced technologies with commercial potential.

Three teams of LLNL scientists and an individual Livermore scientist who worked with a former Laboratory researcher have won plaques from the trade journal R&D Magazine for being among the top 100 industrial innovations worldwide for 2004. They worked with two industrial collaborators.

This year's R&D 100 awards, often called the "Oscars of invention," will be presented Oct. 20 during a black-tie dinner at the Navy Pier Convention Center in Chicago.

"We are pleased by the Laboratory’s continued success in producing leading innovations that benefit the nation and U.S. industry," said Cherry Murray, LLNL's deputy director for Science and Technology. "These technologies reflect the Laboratory’s tradition of multidisciplinary teams working together to solve important national problems."

With this year's four R&D 100 awards, the Laboratory has captured a total of 106 such awards since 1978. This year, Department of Energy (DOE) labs won a total of 29 R&D 100 awards.

"These awards demonstrate that DOE scientists and researchers are hard at work developing the technologies of the future," said Secretary of Energy Samuel Bodman. "In the past, breakthroughs like these have played an important role in both our economic and national security."

Other DOE laboratories winning R&D 100 awards this year were: Argonne National Laboratory, Sandia National Laboratories and Los Alamos National Laboratory, with four awards each; Lawrence Berkeley National Laboratory and Oak Ridge National Laboratory, with three awards each; the National Renewable Energy Laboratory, with two awards; and Brookhaven National Laboratory, Idaho National Laboratory, Pacific Northwest National Laboratory, the Thomas Jefferson National Accelerator Laboratory and Ames Laboratory at Iowa State University, with one award each.

Protecting against bioterrorism

For the third straight year, LLNL researchers have won an R&D 100 award for developing advanced technologies to rapidly detect the airborne release of biological threat agents.

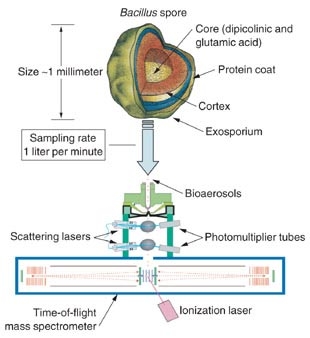

This year’s winner, the Biological Aerosol Mass Spectrometry (BAMS) system, is an instrument about the size of three podiums that can analyze individual aerosol particles in real time and at high rates to almost instantly identify the presence and concentration of harmful biological particles in air samples.

Using a laser to peel cells apart and a mass spectrometer to identify the chemicals inside, BAMS can identify airborne pathogens at the single-cell level in about 100 milliseconds. Combining an understanding of laser-particle interactions, the biochemistry of bacteria and mass spectrometry analysis, BAMS is a prototype system that can identify pathogens and differentiate between harmful anthrax spores and benign agents.

BAMS is designed for operation in office buildings that could be targets for a terrorist attack using a biological agent such as anthrax, or at ports of entry such as airports or train stations to monitor for potential epidemic diseases. Future biomedical applications could include rapid detection of respiratory diseases such as tuberculosis and SARS.

The Livermore employees who developed BAMS come from three directorates - Physics and Advanced Technologies, Chemistry and Materials Science and Engineering. They are: Jim Birch, Keith Coffee, Matthias Frank, David Fergenson, Eric Gard, Norman Madden, Vincent Riot, Abneesh Srivastava, Paul Steele, Herbert Tobias, Todd Weisgraber and Bruce Woods. Funding for the project also came from the Nonproliferation, Arms Control and International Security (NAI) Directorate.

Joining materials in a new way

Reactive NanoTechnologies of Hunt Valley, Md., LLNL, and Johns Hopkins University shared an R&D 100 award for developing a heat source that enables lead-free soldering and brazing of materials at room temperature.

The nanoengineered heat source, dubbed NanoFoil®*, heats only the interface being joined and permits large and small components to be metallically bonded with no thermal damage.

Nearly every product, from computers to airplanes, requires a number of joining steps during manufacturing to form strong and durable metallic bonds that do not damage the materials being bonded. NanoFoil is sold by Reactive NanoTechnologies for different commercial applications.

NanoFoil acts as a rapid and local heat source that replaces the furnaces and torches used in conventional soldering or brazing operations. By sandwiching NanoFoil between two solder layers and the components to be joined, heat generated by a chemical reaction in the foil melts the solder and consequently bonds the components.

NanoFoil is a new class of material and is a unique nanotechnology that was featured last year in the Strategic Plan for the National Nanotechnology Initiative , published by the Executive Office of the President’s Office of Science and Technology Policy.

The development of NanoFoil material was an outgrowth of the technology used to fabricate multilayer X-ray and extreme ultraviolet optics. The salient intellectual property for NanoFoil was created in work on reactive nanolaminate materials initiated and performed in the laboratory of Troy Barbee Jr. in LLNL’s Chemistry and Materials Science Directorate. He received his R&D 100 award for this work. Reactive NanoTechnologies has exclusively licensed nanolaminate technology from LLNL.

*NanoFoil is a registered trademark of Reactive NanoTechnologies, Inc.

Detecting radiation to protect the nation

A team of Livermore researchers has developed the Adaptable Radiation Area Monitor (ARAM), which could play an important role in protecting the nation from radiological or nuclear attack.

Livermore shared its R&D 100 award with Innovative Survivability Technologies (IST) of Goleta, Calif., which licensed the technology in January 2004. IST rapidly transitioned the ARAM technology from the laboratory to production as an easy-to-operate system packaged for use in severe weather.

The ARAM detection system is unique among radiation detectors because of its ability to detect even small quantities of radioactive materials moving at either slow speeds or as fast as 60 miles per hour.

ARAM is a highly sensitive system that uses a thallium-doped sodium iodide crystal to detect small amounts of nuclear material in a number of different scenarios. It can be used as a fixed detector to monitor slow-moving packages, luggage or pedestrians; as a roadside detector to monitor high-speed traffic; or as a portable detector.

Before it was commercialized, ARAM was tested at LLNL and, more recently, it was used as a fixed device to monitor packages for Federal Express in its air cargo facility at the Denver International Airport.

Sponsored by the NAI directorate, the ARAM team was composed of employees from the Chemistry and Materials Science, Computation and Engineering directorates. They are: Dan Archer, Brock Beauchamp, Joe Mauger, Mike Mercer, Karl Nelson, David Pletcher, Vincent Riot, Tom Schaffer (now retired), Jim Schek, Dave Trombino and Guy Urbina.

Seeing the big picture

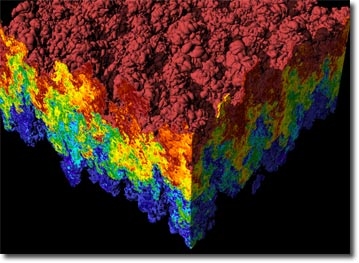

For the second year in a row, Laboratory computer scientists have won an R&D 100 award for developing visualization software. This year’s winner, called VisIt, is a visualization tool geared towards the parallel processing of large amounts of data, including simulations comprising trillions of bytes of data. Problems that require running for days or weeks on the world’s most powerful supercomputers can be visualized and displayed within seconds using VisIt.

To date, VisIt has been downloaded more than 25,000 times by users from throughout the world. This free, interactive parallel visualization and analysis tool operates on one-, two- and three-dimensional data to produce images, movies, and statistical reports. VisIt runs on a multitude of platforms, from Top500 machines like the Advanced Simulation Computing White to smaller parallel platforms using all types of Unix to desktop computers running Windows, Macintosh OS X, or Linux.

At the Laboratory, VisIt has been used to visualize complex physics simulation results including simulations of target capsules for the National Ignition Facility, Rayleigh-Taylor instability codes (where two liquids mix) and the dispersion of airborne chemical releases.

The development of VisIt was sponsored by the Advanced Simulation and Computing Program. The Computation directorate employees who developed VisIt included Eric Brugger, Sean Ahern, Kathleen Bonnell, Hank Childs, Linnea Cook, Jeremy Meredith, Mark Miller, and Brad Whitlock.

In addition to these four awards, another Lab employee – Henry Benner of the Chemistry and Materials Science Directorate – worked on a project at Lawrence Berkeley National Laboratory before he came to LLNL that won an R&D 100 award this year. That project is called "Ion Mobility Analysis for Rapid Identification of Cardiovascular Disease Indicators."

Founded in 1952, Lawrence Livermore National Laboratory has a mission to ensure national security and to apply science and technology to the important issues of our time. Lawrence Livermore National Laboratory is managed by the University of California for the U.S. Department of Energy’s National Nuclear Security Administration.

Contact

Stephen Wampler[email protected]

925-423-3107

Related Links

“When Every Second Counts: Pathogen Identification in Less Than a Minute”RNT Introduces Patented Joining Technology Overcoming Problems of Thermal Damage

“Radiation Detection on the Front Lines”

NAI Technology Showcase (includes ARAM Video)

“From Seeing to Understanding: Livermore computer scientists are revolutionizing the way researchers visualize enormous amounts of supercomputer data”