The Laboratory enters the additive manufacturing arena

You'll be hearing a lot more of those two words in the coming months and years at LLNL.

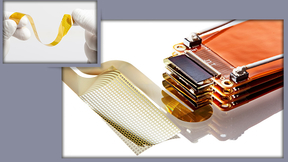

Additive manufacturing (AM) is a new generation of technologies that were actually first developed during the 1970s. But AM has recently become more mainstream with the advent of advances in materials, sensors, micromechanics, computational modeling and simulation.

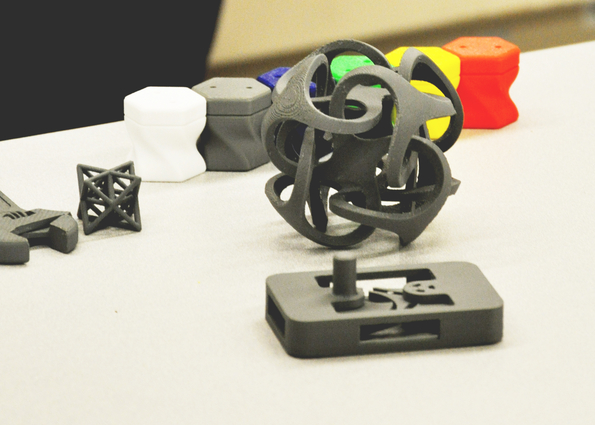

In its simplest form, AM involves creating three-dimensional structures using a machine that sequentially deposits one material on top of another, layer by layer, until the desired shape is complete. It is sometimes called 3D printing, although that term doesn't begin to fully describe the process, which can involve materials with novel properties and shapes.

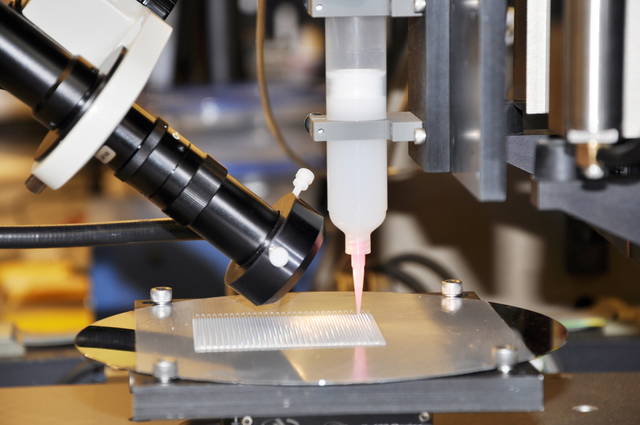

The Laboratory is planning a major push in the field of AM, and has already begun an extensive program of research and development through its Center for Micro and Nano Technology, located in Bldg. 141. The program is led by Chris Spadaccini, Joshua Kuntz and Eric Duoss, along with a team of researchers.

Utilizing newly developed AM technologies will help LLNL achieve its missions with the Department of Energy, departments of Defense and Homeland Security, as well as in development of its energy applications.

But the Lab also has extensive plans to collaborate with U.S. manufacturers to help them become more competitive in the global marketplace, a mission strongly supported by the DOE.

The first step is to understand the needs of private industry.

"They are working with the Laboratory to help us understand the potential needs for manufacturing," said Patrick Dempsey, LLNL's manager of Strategic Engagements, "while at the same time we're helping them understand how we can help them with their manufacturing."

The Laboratory also helped organize an event in Washington, D.C. titled "Additive Manufacturing Symposium -- Preparing for National Prominence in a Disruptive Technology."

Wayne King of LLNL's Condensed Matter and Materials Division, along with staff from The Atlantic Council, the Office of Science and Technology Policy, NIST, DOE, the Institute for Defense Analysis, and Virginia Tech, designed the seminar to:

- Engage policy and research leaders in a dialogue on what potential AM has on the horizon as a disruptive technology.

- Create a working group for dialogue and monitoring of AM research and policy issues.

- Produce a policy report with recommendations on future actions (e.g., foreign and defense policy, regional centers of innovation, standards, regulations, intellectual property) to facilitate national adoption of AM.

Contact

Robert H Hirschfeld[email protected]

925-422-2379

Tags

Advanced Materials and ManufacturingAdditive manufacturing

Engineering

Science

Featured Articles