Lab technology helps companies win Tibbetts Awards

Technology developed by Lawrence Livermore National Laboratory (LLNL) research teams helped two companies win the U.S. Small Business Administration's (SBA)Tibbetts Award recognizing economic impact.

STAR Cryoelectronics, LLC of Santa Fe, New Mexico and Inrad Optics of Northvale, New Jersey -- both of which have licensed LLNL technologies -- are two of 25 companies selected for the award. STAR Cryo is using superconducting tunnel junction (STJ) detectors for high-resolution X-ray spectroscopy and Inrad is using solution-grown organic scintillators for neutron radiation detection.

The awards are given to companies based on whether they have met federal research and development needs, encouraged diverse participation in technological innovation and increased the commercialization of federal research.

LLNL's Industrial Partnerships Office (IPO) was instrumental in finding commercial partners for both technologies and working with STAR Cryo, Inrad and Lab researchers to facilitate a successful commercialization process that ended with licensing agreements.

"It's very rewarding to see small businesses invest in commercializing Lab national security technologies," said Catherine Elizondo, the IPO business development executive, who negotiated the tech transfer deals with STAR Cryo and Inrad Optics.

Analyzing material impurities at the nano level

The STJ X-ray detectors operate at very low temperatures, about 0.1 degree from absolute zero, or -459 F. This enables them to measure X-ray energies more precisely to reveal not only the composition of unknown materials, but also the chemical bonding state of elements in the sample.

The technology has many potential applications in both research and industry that range from X-ray astronomy to material analysis.

"The semiconductor industry cares about smaller and smaller impurities that get into the chip fabrication process, which causes the chip to fail and reduces the manufacturing yield," said LLNL physicist Stephan Friedrich, who developed the detectors. "Our detector can analyze impurities at the nano level."

LLNL and STAR Cryo are collaborating on STJ detectors that offer more than a ten-fold improvement in energy resolution as compared with conventional silicon or germanium detectors, said company president Robin Cantor.

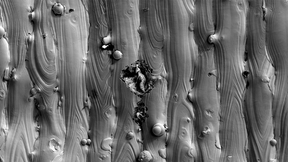

To operate the STJ detectors --which look like a large computer chip -- STAR Cryo also developed an advanced refrigerator technology. These refrigerators use a two-stage pulse tube cryocooler to precool the detector to 3 Kelvin, and then a two-stage adiabatic demagnetization refrigerator (ADR) obtains a base temperature below 0.1 Kelvin. The refrigerator is fully automated without using liquid nitrogen or expensive helium, saving time and money.

"This collaboration with LLNL has been very successful in terms of scientific output as well as contracts and commercial opportunities available through the Industrial Partnerships Office," Cantor said.

Growing crystals for portable radiation detectors

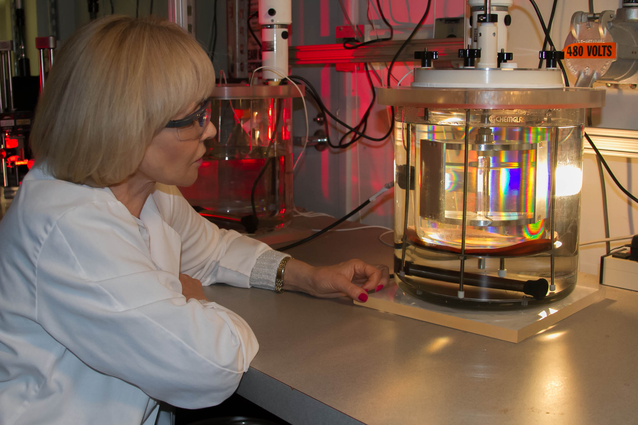

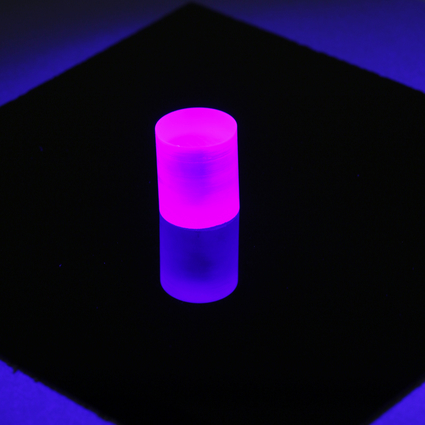

Meanwhile, an LLNL team that includes Natalia Zaitseva, Leslie Carman and Andrew Glenn made a breakthrough by developing solution-grown stilbene crystals that have scintillation capabilities (amount of light produced as a response to neutrons) that exceed stilbene crystals grown by using the common melt-growth technique. Stilbene is a single crystal used for a type of radiation detection known as pulse-shape discrimination (PSD).

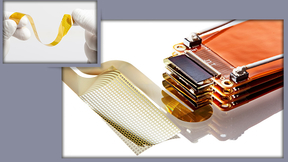

The melt-growth technique is a high-temperature process in which crystallization is conducted by cooling an initial liquid melt until it becomes a solid. During the solution-grown process developed by LLNL, stilbene is grown using crystallization tanks and seed holders to handle organic solutions to improve the growth process with controlled temperature reduction during the crystal's rotation.

"The solution method used for stilbene production is based on technology developed previously for growth of super-large KDP [potassium dihydrogen phosphate] crystals for the National Ignition Facility," said Zaitseva, the physicist who is the project's principal investigator.

These crystals can potentially be used in portable and non-portable neutron radiation detection devices to detect illicit nuclear weapons at ports of entry, security checkpoints, sensitive city installations as well as scanning equipment for wide area sweeping at offshore facilities or onboard ships. They can be used for monitoring nuclear power plants for dangerous or unhealthy levels of radiation from leakage. They also can be used as scientific measurements of neutron emitters, such as in a laboratory or classroom setting.

The LLNL team's solution-grown crystals are faster and cheaper to produce than stilbene crystals using a melt-growth method; can quickly detect neutrons in the presence of a strong gamma ray background; and have good luminescence properties. The team is collaborating with Inrad to develop the crystals for neutron detection applications.

"Until now, only one option existed for detection of fast neutrons," said Amy Eskilson, Inrad Optics' president and CEO.

Candace Lynch, Inrad Optics' senior crystal growth scientist, said LLNL's solution-grown scintillator technology is important because it demonstrates a more scalable, more economical route for production of a material with superior properties for detection of fast neutrons. The company has begun commercial sales of stilbene scintillation crystals.

In addition to the Tibbetts Award, Zaitseva and Inrad Optics also were recently honored by the Department of Homeland Security's Domestic Nuclear Detection Office for exceptional contributions to advanced materials development for neutron detection of radiological and nuclear material.

"It's a great recognition of our team's scientific achievements, which helped to develop a commercial product important for the mission of DNDO," Zaitseva said.

Eskilson said: "We are honored to receive these awards and to contribute to technologies that will help keep Americans safe from nuclear threats. Working with Lawrence Livermore has been a great experience, both from the technical perspective with the scientists and from the experts at the Lab's Industrial Partnerships Office."

Contact

Kenneth K Ma[email protected]

925-423-7602

Related Links

Inrad OpticsSTAR Cryoelectronics

U.S. Small Business Administration

LLNL Industrial Partnerships Office

Department of Homeland Security's Domestic Nuclear Detection Office

Tibbetts Awards

Related Files

DownloadTags

EngineeringFeatured Articles