Lab study of droplet dynamics advances 3D printing

(Download Image)

(Download Image)

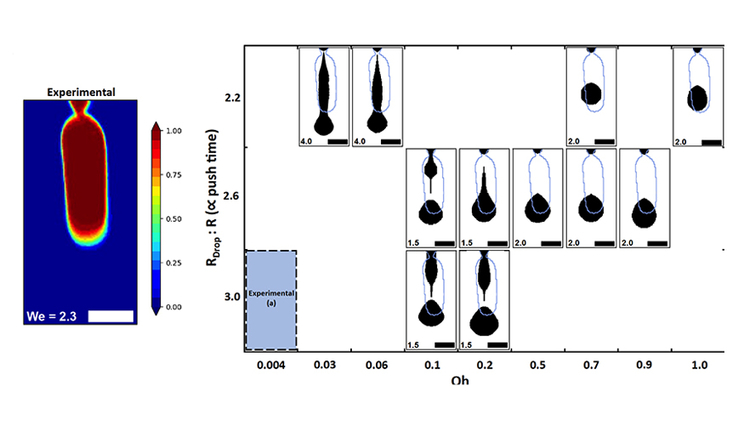

A comparison between the experimentally observed ejected droplet shape at break-up (a) and the simulated droplet shape (b) at various operating conditions approaching the experimental conditions. The simulated droplet shape significantly differs from experiments, highlighting the fact that essential physics appear to be missing from the model. Image courtesy of Andy Pascall/LLNL.

A team of Lawrence Livermore National Laboratory (LLNL) scientists has simulated the droplet ejection process in an emerging metal 3D printing technique called “Liquid Metal Jetting” (LMJ), a critical aspect to the continued advancement of liquid metal printing technologies.

In the paper, the team describes the simulating of metal droplets during LMJ, a novel process in which molten droplets of liquid metal are jetted from a nozzle to 3D print a part in layers. The process does not require lasers or metal powder and is more similar to inkjet printing techniques.

Using the model, researchers studied the primary breakup dynamics of the metal droplets, essential to improving the understanding of LMJ. LMJ has advantages over powder-based approaches in that it provides a wider material set and does not require production or handling of potentially hazardous powders, researchers said. The journal Physics of Fluids published the study on Nov. 25, where it was chosen as an Editor’s Pick.

“We don’t currently have a good understanding of all of the physics that occur right when the droplet breaks off from the metal jet,” said co-author Andy Pascall. “This model points to additional physical mechanisms that might need to be considered to close the gap between experiments and modeling."

To conduct the research, the team built a custom, liquid-metal printer capable of dispensing tin droplets. Combined with high-speed video, the printer served as an experimental test-bed for free-form, droplet-on-demand printing and allowed the team to track detailed droplet dynamics during the ejection process.

The video analysis enabled researchers to build a computational model to simulate the morphology of the metal droplets during ejection, revealing that the drops behave like an extruded “pill” with no tail formation.

The study demonstrates that while LMJ is highly stable and repeatable, it also is extremely challenging to model. In the future, the team plans to explore droplet ejection across a broader range of process parameters and seek greater understanding of the factors impacting droplet shape, breakup and satellite formation, including thermal effects, wettability and the role of surface oxides.

The Laboratory Directed Research and Development program funded the work. Co-authors include Victor Beck, Nicholas Watkins, Ava Ashby, Aiden Martin, Phillip Paul and principal investigator Jason Jeffries.

Contact

Jeremy Thomas

Jeremy Thomas

[email protected]

(925) 422-5539

Related Links

Physics of FluidsTags

Advanced Materials and ManufacturingMaterials Science

Physics

HPC, Simulation, and Data Science

Computing

Engineering

Physical and Life Sciences

Featured Articles