LAB REPORT

Science and Technology Making Headlines

Sept. 4, 2020

Lawrence Livermore's Community Emergency Response Team member Roberta LoGrande was one of more than 20 employees who staffed Cal Fire’s information center at the Alameda County Fairgrounds during the SCU Complex Fire.

In the thick of it

When a severe lightning storm sparked what would become a conflagration consuming more than 390,000 acres and threatening the communities of Livermore and Pleasanton, volunteers with Lawrence Livermore National Laboratory’s Community Emergency Response Team (CERT) answered the state’s call for help.

Ignited by unusual summer thunderstorms in the early morning hours of Aug. 16, the blaze eventually dubbed the SCU Lightning Complex Fire quickly grew to burn portions of five counties, briefly shuttering LLNL’s Site 300 and creeping within miles of the main Lab campus. Due to the massive size of the fire and its proximity to the Livermore area, on Aug. 19, Cal Fire, through the state’s Office of Emergency Services, reached out to LLNL’s CERT for assistance, as part of California’s Emergency Mutual Aid agreement. It was the first time Cal Fire had called upon the Lab CERT team to respond to a major incident.

On Aug. 23, working with CalFire Incident Management Team No. 6, CERT members began reporting to the Cal Fire base camp at the Alameda County Fairgrounds in Pleasanton to staff the agency’s fire information call center. For the next week, working six-hour shifts, including midnight and swing shifts, the more than 20 Lab volunteers answered hundreds of phone calls from concerned residents, providing them with updated information on evacuations, telling evacuees if and when they could return home and instructing them on relocating their livestock. Volunteers also helped with food delivery and training in support duties. By the end of the week, CERT members had worked a total of 57 shifts, including overnights, with many members volunteering more than 30 hours.

A trilayer laminate mimicking a protective military garment and consisting of a nylon/cotton outer-shell fabric with a camouflage pattern, an intermediate protective carbon nanotube membrane layer and a cotton comfort liner.

Saving one’s skin

For those working in war zones poisoned with sarin gas, protective clothing is everything. The invisible chemical weapon is odorless and frequently lethal, so traditional personal protection equipment is heavy and non-breathable. But for first responders and soldiers most likely to encounter chemical weapons in chaotic moments, heavy and non-breathable are dangerous.

“If you are wearing protective suits, you typically have to limit usage to an hour or so before your body temperature spikes to a dangerous level,” says Francesco Fornasiero, a staff scientist in chemical engineering at Lawrence Livermore. “In a worst-case scenario, you could get a heat stroke.”

Fornasiero says these life-or-death situations need new, smart materials that can sense a threat like sarin and respond automatically to block it. Scientists at MIT and Lawrence Livermore have invented a thin, breathable membrane fabric made of carbon nanotubes. The nanotubes, a mainstay in Department of Defense-funded research because of their lightness and durability, are capped with a specially designed polymer that shape-shifts as soon as it senses a chemical or biological weapon. That shape-shifting temporarily closes off the tiny pores automatically.

Fornasiero likens the shape-shifting polymers to sticky strings. Under normal conditions, air and water vapor travel freely through the pores and past the upright strings. But when chemical or biological molecules are around, the strings interact with the molecule’s distinct chemistry, causing them to contort and stick to each other. That collapse of strings clogs up the pores, preventing the chemical or biological agent from entering.

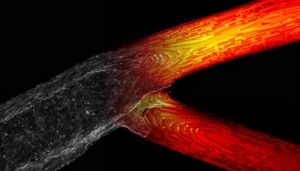

LLNL combined 3D bioprinting and computational flow models to analyze the physics behind circulating tumor cell behavior and the cells’ attachment to the vascular endothelium, the layer of cells that line the interior surface of blood vessels. Visualization by Claire Robertson/LLNL.

Tracking the spread in 3D

Lawrence Livermore scientists have paired 3D-printed, living human brain vasculature with advanced computational flow simulations to better understand tumor cell attachment to blood vessels, the first step in secondary tumor formation during cancer metastasis. The unique approach, developed with outside collaborators, lays the foundation for developing a predictive capability that can help clinicians and researchers anticipate the spread of cancer within individual patients, according to LLNL researchers.

The research creates a new approach to training computational models on biological processes and provides insights into how and why cancer cells metastasize in certain areas of the vasculature.

The team, which includes scientists at Duke University, combined bioengineering and computation to analyze the physics behind circulating tumor cell behavior and the cells’ attachment to the vascular endothelium, the layer of cells that line the interior surface of blood vessels.

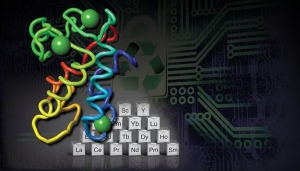

This illustration depicts lanmodulin, a small protein that is a bio-sourced alternative to extract, purify and recycle rare earth elements from various sources. Illustration by Thomas Reason/LLNL.

A rare find

Rare-earth metals are essential parts of electronic components in phones, vehicles, displays and wind turbines. A new Lawrence Livermore study shows that a recently discovered protein from bacteria outperforms many current methods for extracting these elements from waste streams while potentially being more environmentally friendly

Concentrated amounts of rare-earth metals, also called lanthanides, are only found in a few ore deposits around the world. More abundant but far more dilute sources of these materials include electronic waste and rare-earth-containing coals. But these sources are rarely economical to tap because the current methods for collection, which mainly involve solvent extraction, are inefficient and produce large amounts of toxic compounds.

In the new work, the team wanted to see if the protein could be useful in extracting these elements. They compared lanmodulin’s ability to pull lanthanides out of streams of electronic waste and rare-earth-containing coal with the traditional chelators used in current rare-earth processing plants. Lanmodulin was orders of magnitude more selective, capturing neodymium and europium ions while leaving behind ions present at higher concentrations in the waste streams, such as iron and zinc.

Lanmodulin “has a huge appetite for rare-earth metals and basically nothing else,” said study author Gauthier Deblonde of LLNL.

Tungsten’s high melting and boiling points make it popular for use in lightbulb filaments and arc welding.

Cracked open

Tungsten has the highest melting and boiling points of all known elements, making it a popular choice for applications involving extreme temperatures, including lightbulb filaments, arc welding, radiation shielding and, more recently, as a plasma-facing material in fusion reactors such as the ITER Tokamak.

However, tungsten’s inherent brittleness, and the microcracking that occurs within the material during PBF-LB AM, currently pose challenges to its widespread adoption. Previous research into microcracking in tungsten has been limited to examining cracks post-build, but observing the build process in re-examining cracks post-build, but observing the build process in real-time allowed LLNL’s scientists to observe how microcracks initiated and spread as the metal heated and cooled.

Thanks to this real-time perspective on the process, the team was able to correlate the microcracking phenomenon with variables such as residual stress, strain rate and temperature, and confirm that the ductile-to-brittle (DTB) transformation of the material was the cause of the cracking.