LAB REPORT

Science and Technology Making Headlines

Jan. 15, 2021

Behind a great Lab are great people

For the third consecutive year, Lawrence Livermore has been honored with a Glassdoor Employees’ Choice Award, recognizing the best places to work in 2021.

The Employees’ Choice Award, now in its 13th year, is based on the input of employees who elect to provide anonymous feedback by completing a company review about their job, work environment and employer on Glassdoor, a leader on insights about jobs and companies.

This is the third year the laboratory has ranked on Glassdoor’s top 25 “Best Places to Work U.S Large.” This year, LLNL ranked 23 out of 100. Glassdoor’s average company rating is a 3.5 and LLNL received an impressive company rating of 4.4 during the review period and maintains a 4.7 cumulative rating. Other accolades include LLNL being the No. 1 government/government contractor employer and the No. 1 laboratory employer. LLNL also is No. 9 on the list of large employers in the Bay Area and No. 5 of those headquartered in San Francisco.

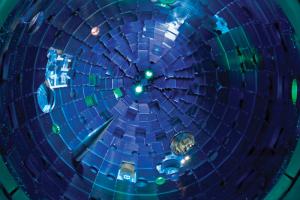

Pulses from NIF’s high-powered lasers race toward the target bay at the speed of light. They arrive at the center of the target chamber within a few trillionths of a second of each other, aligned to the accuracy of the diameter of a human hair.

Pushing the boundaries

If you want to see lasers that push the boundaries of the possible in the most dramatic of ways, you have to turn to those made to further science. Wherever researchers require massive amounts of power or precision, there’s every chance that they are using a laser, some sort of digital photon detector, or both. To see the cutting edge of what light can do, head for a lab.

The National Ignition Facility (NIF) at Lawrence Livermore National Laboratory is a case in point. The 192 laser beams from the 100-meter-long, xenon-pumped beamlines that fill its two warehouse-sized clean rooms converge on a peculiarly perforated spherical chamber. When NIF is operational, a tiny bubble at the center of that chamber is illuminated with 500 terawatts (TW).

Given that the world’s total electricity generating capacity is less than 5TW, how is a 500TW system possible? The answer is brevity. Because power is energy divided by time, a relatively small amount of energy can provide a huge amount of power if it is delivered quickly enough. NIF fires for only a few tens of nanoseconds (billionths of a second) at a time. Each blink-and-you-miss-it 500TW blast thus delivers only a kilowatt-hour or so of energy.

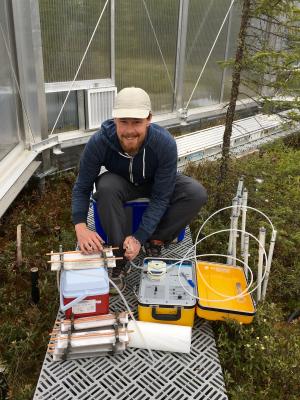

Ate Visser, an LLNL hydrologist, collects groundwater samples in copper tubes for helium isotope analyses. The tests reveal the age of the water. Photo by Karis McFarlane/LLNL.

Here today, gone tomorrow

New research on fossil water from Lawrence Livermore National Laboratory suggests that drinking wells that pump such water can’t rely on it being replenished — especially during times of drought.

Buried deep within the earth lies fossil water — ancient aquifers, created by rain and snow that fell more than 10,000 years ago. Unless the fossil water stores are better protected, scientists say, they may become a thing of the past.

The new study found clear evidence that 7 percent of the 2,330 California drinking wells tested are producing fossil water — and 22 percent of the wells analyzed are pumping mixed-age water containing at least some ancient water. That means that many Californians are already using fossil water to shower, flush their toilets and irrigate their lawns without knowing it.

Because fossil water fell from the sky thousands of years ago, there’s a greater risk of depleting the resource, scientists say. “It’s kind of like a bank account,” said Ate Visser, an LLNL research scientist. “If you start withdrawing from your bank account but you have no income, at some point it’s going to run out.”

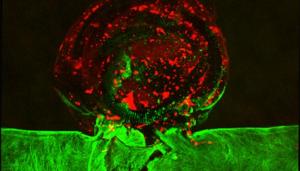

Using 3D printing, an LLNL team replicated an aneurysm in vitro and performed an endovascular repair procedure, inserting a catheter into the blood vessel and tightly packing platinum coils inside the aneurysm sac. The team introduced blood plasma into the aneurysm and observed a blood clot form where the coils were located. The green areas depict the endothelial cells and the red indicates the formed clot. Photo by Elisa Wasson.

A brain aneurysm in a dish

Brain aneurysms, which affect as many as one in 50 people, occur when a blood vessel wall weakens and bulges, setting the scene for a potentially deadly rupture.

Now scientists at Lawrence Livermore and Texas A&M University have created a 3D-printed aneurysm model in the laboratory and “operated” on it: they inserted a device to seal it off and prevent it from bursting. Such models could be tailored to replicate an individual patient's blood vessel, letting doctors try different treatments and find the best solution.

To treat an aneurysm, brain surgeons sometimes operate to install a metal clip on the ballooning vessel that prevents the pooling of blood. A less invasive method involves inserting tiny metal coils into the aneurysm via a catheter to induce a blood clot that seals it off. Most treatment devices are tested in animals, whose blood vessels do not perfectly resemble those in humans. And previous lab-dish aneurysms could not mimic the properties of living blood vessels.

The team 3-D-printed an aneurysm structure with a water-based gel and populated it with human cells that line the brain's blood vessels. They then operated on the aneurysm, injecting platinum coils into the bulging vessel. Finally, they filled the blood vessel with plasma (the liquid component of blood), which formed a clot that sealed off the bulge.

LLNL researchers have found that the current locations of many planetary bodies in the solar system are not where they originally formed. Image courtesy of NASA.

The solar system reconstructed

A team of scientists from Lawrence Livermore decided to reconstruct the original solar system and discovered that planets didn't start out in their current locations.

As the solar system was born, some of the most massive planets (Saturn and Jupiter) developed quickly. As they formed, they moved closer and further away from the sun. The reason? They wanted to stay in gravitationally steady orbits.

Now, scientists want to reach those moments and develop almost the same architecture. According to the team, the most substantial rearrangement of the early solar system due to massive planet movement has hindered our knowledge of where cosmic bodies developed.

By examining the development of meteorites from the asteroid belt, the team found out their host bodies must have accumulated from various areas in the initial solar system.

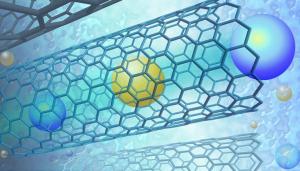

Artistic rendering of fast ion permeation inside single-walled carbon nanotubes. Small ions such as potassium, chloride and sodium permeate through the inner volume of nanometer-wide carbon nanotubes at rates that surpass diffusion in bulk water by an order of magnitude. Image by Francesco Fornasiero/LLNL.

Dialysis in a jiffy

Scientist from Lawrence Livermore National Laboratory have found that ultra-rapid dialysis processes could be achieved by carbon nanotube membrane pores, resulting in considerably reduced treatment time for patients undergoing hemodialysis.

In man-made and biological processes, the potential to isolate molecular components in complex solutions is very important. One way to do this is to apply a concentration gradient across a porous membrane. This method fuels molecules or ions that are smaller in comparison to the pore diameters from one side of the membrane to the other, while preventing anything that is too large to accommodate through the pores.

In nature, biological membranes, like those in the liver or kidneys, carry out complex filtrations and, at the same time, maintain a high throughput. But synthetic membranes usually struggle with a familiar trade-off between permeability and selectivity. The same material characteristics that control what can and cannot travel via the membrane inexorably decrease the speed at which filtration can take place.

In an unexpected finding, the team discovered that carbon nanotube pores (that is, graphite cylinders that have thousands of times smaller diameters than a single strand of human hair) may offer a solution to the trade-off between permeability and selectivity.