LAB REPORT

Science and Technology Making Headlines

May 27, 2016

Dawn Shaughnessy prepares a sample for chemical analysis.

Cracking the Top 10

Lawrence Livermore National Laboratory chemist Dawn Shaughnessy has been named No. 9 on Fast Company’s Top 100 Most Creative People in Business for 2016.

Shaughnessy is the principal investigator of the Heavy Element Group, where she has worked as a nuclear and radiochemist since 2002. In December, the International Union of Pure and Applied Chemistry added three new entries to the periodic table of elements that had been synthesized by a team of researchers led by Shaughnessy. Partnering with the Joint Institute for Nuclear Research in Russia, the group has discovered five new “superheavy” elements since 2004, bearing the atomic numbers 114 to 118 with element 116 named Livermorium in honor of the Laboratory.

This year's list of Fast Company’s 100 Most Creative People spans educators to scientists, jazz saxophonists to startup founders, fashion designers to rappers. It includes individuals from Apple, Valentino, Slack, Nike, BuzzFeed and more — from Italy to Costa Rica, Turkey and Nigeria.

LLNL researcher Megan Bruck Syal examines a pair of meteorites destined to be vaporized by high-powered lasers. Photo by Julie Russell/LLNL

Watch out for that comet

To save mankind from a doomsday collision with a comet, Lawrence Livermore planetary scientist Megan Bruck Syal is working with small meteorites — space rocks formed at the dawn of the solar system that drifted through space for billions of years before crashing into Earth.

“Nobody has really looked at meteorites in this way before, under these high-pressure conditions, so we’re doing something new and it’s difficult in a lot of ways when you do something new,” Bruck Syal said. “[They] came a long way and we’re pretty lucky to get to use them,” she added.

Using them also means destroying them, because Bruck Syal and her team are considering two possible ways to deflect a killer asteroid.

Jiun Chang, a UC Merced graduate student working at LLNL, studies cartilage degeneration in an anterior cruciate ligament (ACL) injury in a mouse model. Photo by Julie Russell/LLNL

Preventing ‘wear and tear’

Joint injury can lead to post-traumatic osteoarthritis (PTOA). In fact, about half of all people who rupture the anterior cruciate ligament (ACL) in their knee will develop PTOA within 10 to 20 years of the injury.

But the molecular and cellular mechanisms leading to cartilage degeneration or PTOA due to trauma are not well understood. Recently, a team of scientists from Lawrence Livermore and collaborators examined the whole-joint gene expression by RNA sequencing at one day and one, six and 12 weeks after injury.

Sometimes called degenerative joint disease or “wear and tear” arthritis, osteoarthritis (OA) is the most common chronic condition of the joints. It occurs when the cartilage or cushion between joints breaks down, leading to pain, stiffness and swelling.

The goal of the new research could personalize medical treatment before the disease is all consuming. Most importantly, treatments could be developed that, when administered immediately post injury, would prevent the development of PTOA years later.

Element 117 was first discovered by Lawrence Livermore researchers and Russian collaborators. It has yet to be named.

It’s getting heavy in here

The periodic table is about to get a little bit longer thanks to the addition of four new super-heavy elements.

The discoveries of elements 113, 115, 117 and 118 were officially confirmed by the International Union of Pure and Applied Chemistry. The group is tasked with vetting the man-made elements seeking a permanent spot on the chart that adorns chemistry classrooms around the world. Lawrence Livermore scientists have found five of the most recently discovered elements, elements 114-118, with element 116 named livermorium after the Lab.

The new elements are known as super-heavy elements because the nuclei of their atoms are so enormous. Element 118, for example, is the heaviest element to date, with 118 protons alongside 176 neutrons.

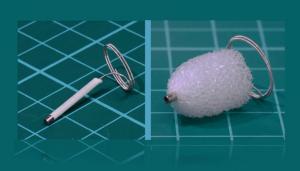

Microstructures of two different foam materials. At left, a traditional open-cell stochastic foam, and at right, a 3-D printed foam with the face-centered tetragonal lattice structure

One foam is better than the other

Lawrence Livermore National Laboratory (LLNL) material scientists have found that 3-D-printed foam works better than standard cellular materials in terms of durability and long-term mechanical performance.

Foams, also known as cellular solids, are an important class of materials with applications ranging from thermal insulation and shock-absorbing support cushions to lightweight structural and floatation components. Such material is an essential component in a large number of industries, including automotive, aerospace, electronics, marine, biomedical, packaging and defense. Traditionally, foams are created by processes that lead to a highly non-uniform structure with significant dispersion in size, shape, thickness, connectedness and topology of its constituent cells.

As an improved alternative, scientists at the additive manufacturing lab at LLNL recently demonstrated the feasibility of 3-D printing of uniform foam structures through a process called direct-ink-write. However, since 3-D printing requires the use of polymers of certain properties, it is important to understand the long-term mechanical stability of such printed materials before they can be commercialized. This is especially vital in applications such as support cushions, where the foam material is subjected to long-term mechanical stresses.